Hard carbon cathode material for lithium ion power and energy storage battery and preparation method of hard carbon cathode material

A negative electrode material, hard carbon technology, applied in battery electrodes, carbon preparation/purification, circuits, etc., can solve the problems that the electrical properties of negative electrode materials cannot meet the needs, cannot meet the needs, and the reversible capacity is low, and the first Coulomb efficiency is large. , low cost, and the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Pre-curing: add 15 g of dopant ammonium dihydrogen phosphate to 60 g of furfural phenol resin, use a high-speed disperser at a speed of 2800r / min, and cure for 30 minutes in air at 250°C for 4 hours to obtain pre-curing Precursor.

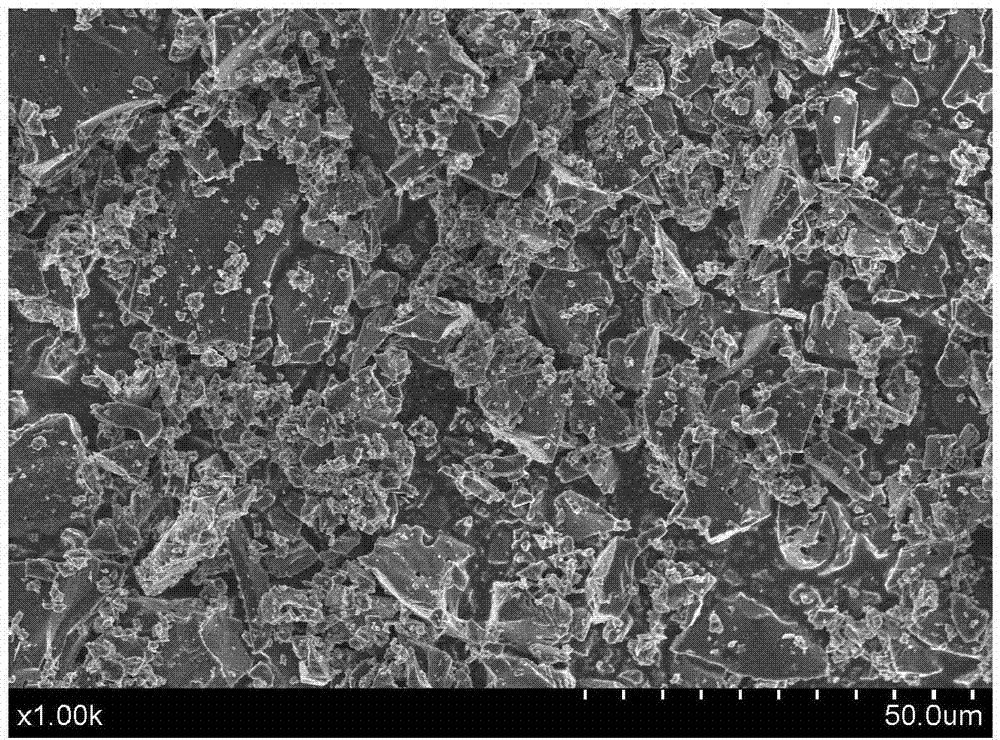

[0062] (2) Crushing: The pre-cured precursor is ball-milled with a planetary ball mill to obtain powder particles with an average particle size of 20 μm.

[0063] (3) Curing: 25g of curing agent hexamethylenediamine was added to the powder, stirred evenly, and cured in air at 200°C for 12 hours to obtain a solid precursor.

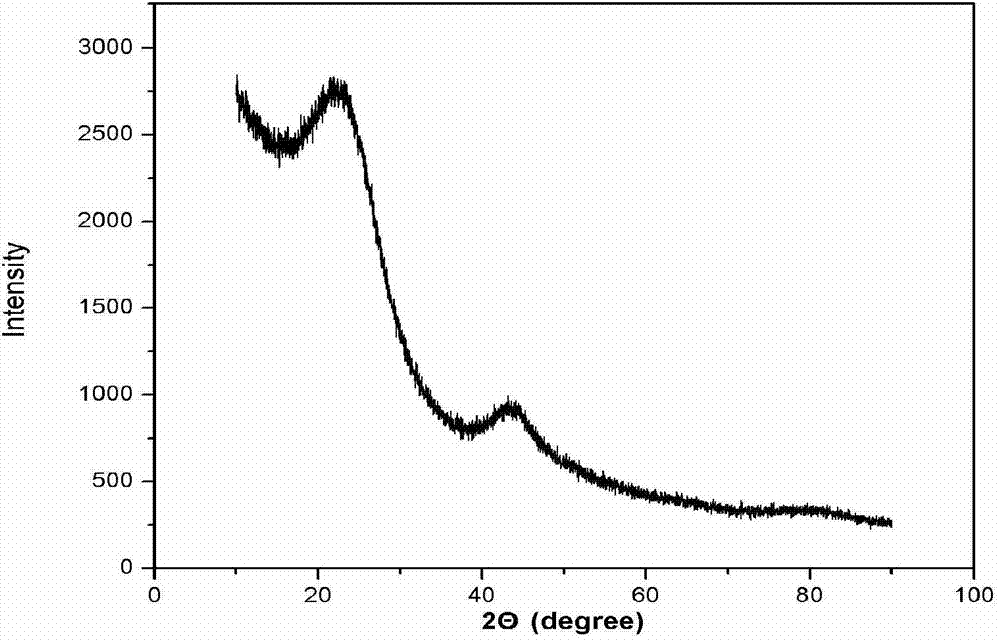

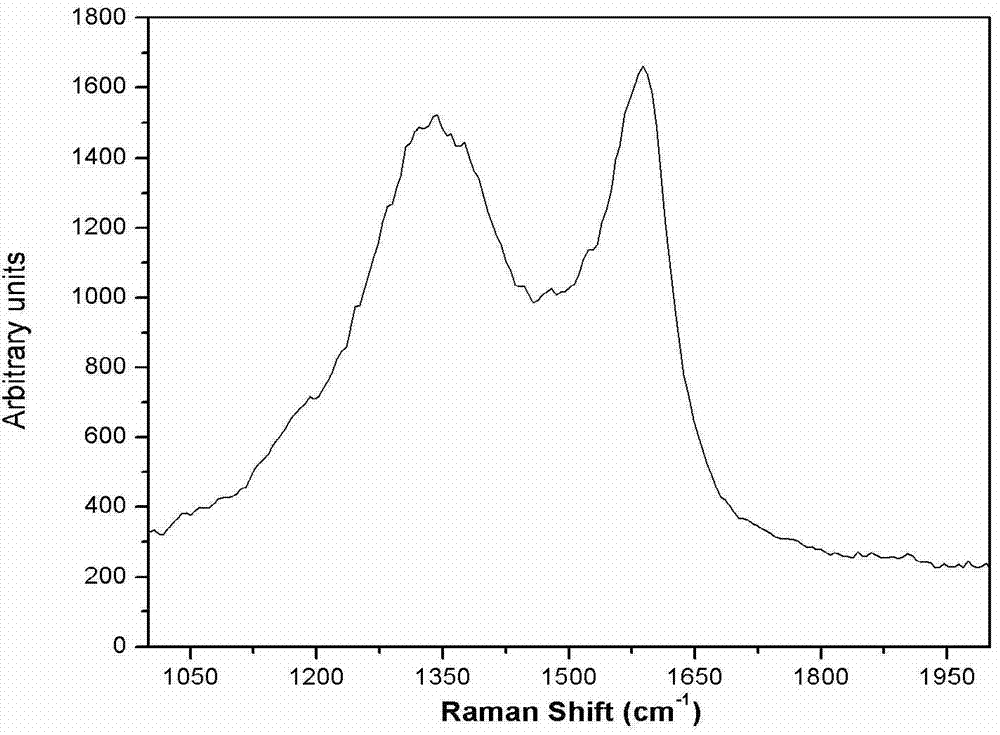

[0064] (4) Pyrolysis: put the cured precursor into a box-type resistance furnace, heat up to 1050°C at a heating rate of 10°C / min, pyrolyze for 1 hour, and cool down to room temperature naturally to obtain hard carbon. The pyrolysis is carried out under a nitrogen atmosphere , the nitrogen flow rate is 0.3m 3 / h.

[0065] (5) Crushing: use a planetary ball mill to grind the hard carbon balls to an average particle...

Embodiment 2

[0068] (1) Pre-curing: Add 10 g of dopant phosphoric acid to 80 g of phenolic resin, use a high-speed disperser at a speed of 2000 r / min, and cure for 60 minutes in air at 200°C for 6 hours to obtain a pre-cured precursor.

[0069] (2) Crushing: The pre-cured precursor was ball-milled with a planetary ball mill to obtain powder particles with an average particle size of 24 μm.

[0070] (3) Curing: 10 g of curing agent melamine was added to the powder, stirred evenly, and cured in air at 220° C. for 6 hours to obtain a solid precursor.

[0071] (4) Pyrolysis: put the cured precursor into a box-type resistance furnace, heat up to 950°C at a heating rate of 5°C / min, pyrolyze for 2 hours, and cool down to room temperature naturally to obtain hard carbon. The pyrolysis is carried out under a nitrogen atmosphere , the nitrogen flow rate is 0.4m 3 / h.

[0072] (5) Crushing: use a planetary ball mill to grind the hard carbon balls to an average particle size of 10 μm to obtain a har...

Embodiment 3

[0075] (1) Pre-curing: Add 15 g of dopant boric acid to 70 g of epoxy resin, use a high-speed disperser at a speed of 1200 r / min, and cure for 120 min in air at 150°C for 8 hours to obtain a pre-cured precursor.

[0076] (2) Crushing: The pre-cured precursor is ball-milled with a planetary ball mill to obtain powder particles with an average particle size of 22 μm.

[0077] (3) Curing: 15g of curing agent phthalic anhydride was added to the powder, stirred evenly, and cured in air at 80°C for 20 hours to obtain a solid precursor.

[0078] (4) Pyrolysis: put the cured precursor into a box-type resistance furnace, heat up to 950°C at a heating rate of 12°C / min, pyrolyze for 1 hour, and cool down to room temperature naturally to produce hard carbon. The pyrolysis is carried out under a nitrogen atmosphere , the nitrogen flow rate is 0.4m 3 / h.

[0079] (5) Crushing: use a planetary ball mill to grind the hard carbon balls to an average particle size of 16 μm to obtain a hard ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com