Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

A compound and mixture technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low efficiency, achieve good dispersion uniformity, avoid precipitation, and improve Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Synthesis of the complex:

[0076] (1) Take 5Kg Si powder, 10Kg SiO 2 Powder, put into VC mixer and mix for 30min to get SiO 2 and the mixture of Si, the mixture is put into the end of the vacuum furnace near the end of the furnace as a raw material for preparing silicon oxide;

[0077] (2) get 10Kg dolomite, 5Kg ferrosilicon powder, after dropping into VC mixer and mix 30min, obtain the mixture of 15Kg dolomite and ferrosilicon powder, put this mixture into the vacuum furnace as the raw material of preparing Mg near the end of furnace mouth;

[0078] (3) A collector is placed in the collection chamber, heated to 1350°C under a negative pressure of 3 Pa and kept warm for 24 hours, so that SiO vapor and Mg vapor are generated in the furnace, and the uniformly mixed gaseous mixture undergoes rapid condensation (condensed The temperature is 900°C) to generate SiOx-Mg material, named as modified SiO X After the reaction, the equipment was cooled and 15Kg of product was c...

Embodiment 2

[0092] Except in the synthesis process of the composite, the operation of step (1) and step (2) is changed to: the obtained SiO 2 The mixture with Si and the obtained raw materials for preparing Mg are first mixed, and then the mixed mixture is put into a vacuum furnace. Other preparation methods and conditions are the same as in Example 1.

[0093] Compound tests:

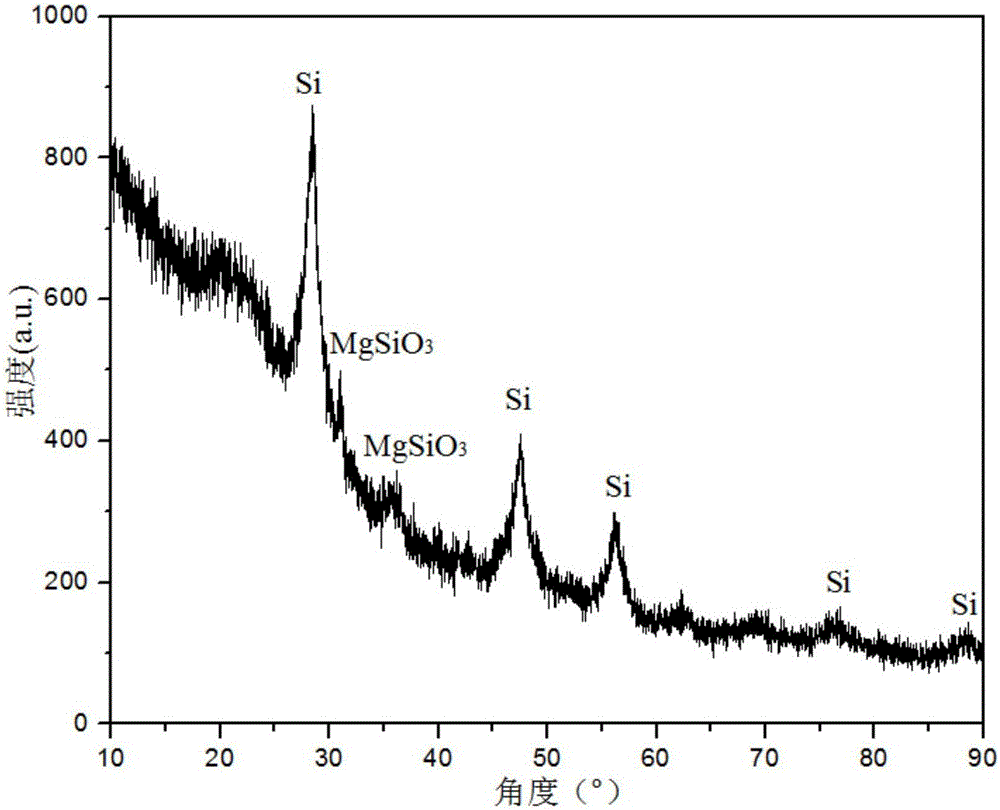

[0094] Use X-ray diffractometer to carry out qualitative analysis to the compound that present embodiment makes, and detection result is the same as that in embodiment 1 figure 1 Similarly, the characteristic peaks of magnesium silicate formed after the reaction of Mg and SiO and the characteristic peaks of Si appeared in the prepared composite, but the peak of Mg did not appear. Silicon oxide SiO x (0<x≤2) is amorphous and thus not shown in the XRD pattern.

[0095] In the compound that the present invention obtains, comprise silicon, silicon oxide SiO x , 0<x≤2, magnesium silicate, does not contain Mg elemen...

Embodiment 3

[0101] Except in the synthetic process of composite, the operation of step (1) and step (2) is replaced as: replace the raw material of preparing Mg with 2Kg magnesium powder, and it is mixed with the obtained SiO 2 Mix evenly with the mixture of Si, put into vacuum furnace, other preparation methods and conditions are identical with embodiment 1.

[0102] Compound tests:

[0103] Use X-ray diffractometer to carry out qualitative analysis to the complex that the present embodiment makes, and detection result is the same as that in Example 1. figure 1 Similarly, the characteristic peaks of the silicate formed after the reaction of Mg and SiO and the characteristic peaks of Si appeared in the prepared composite, but the peak of Mg did not appear.

[0104] Silicon oxide SiO x (0<x≤2) is amorphous and thus not shown in the XRD pattern.

[0105] In the compound that the present invention obtains, comprise silicon, silicon oxide SiO x , 0<x≤2, magnesium silicate, does not contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com