Silicon and carbon negative electrode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems that affect applications, poor conductivity, and environmental protection, and achieve no decline in conductivity , stable structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

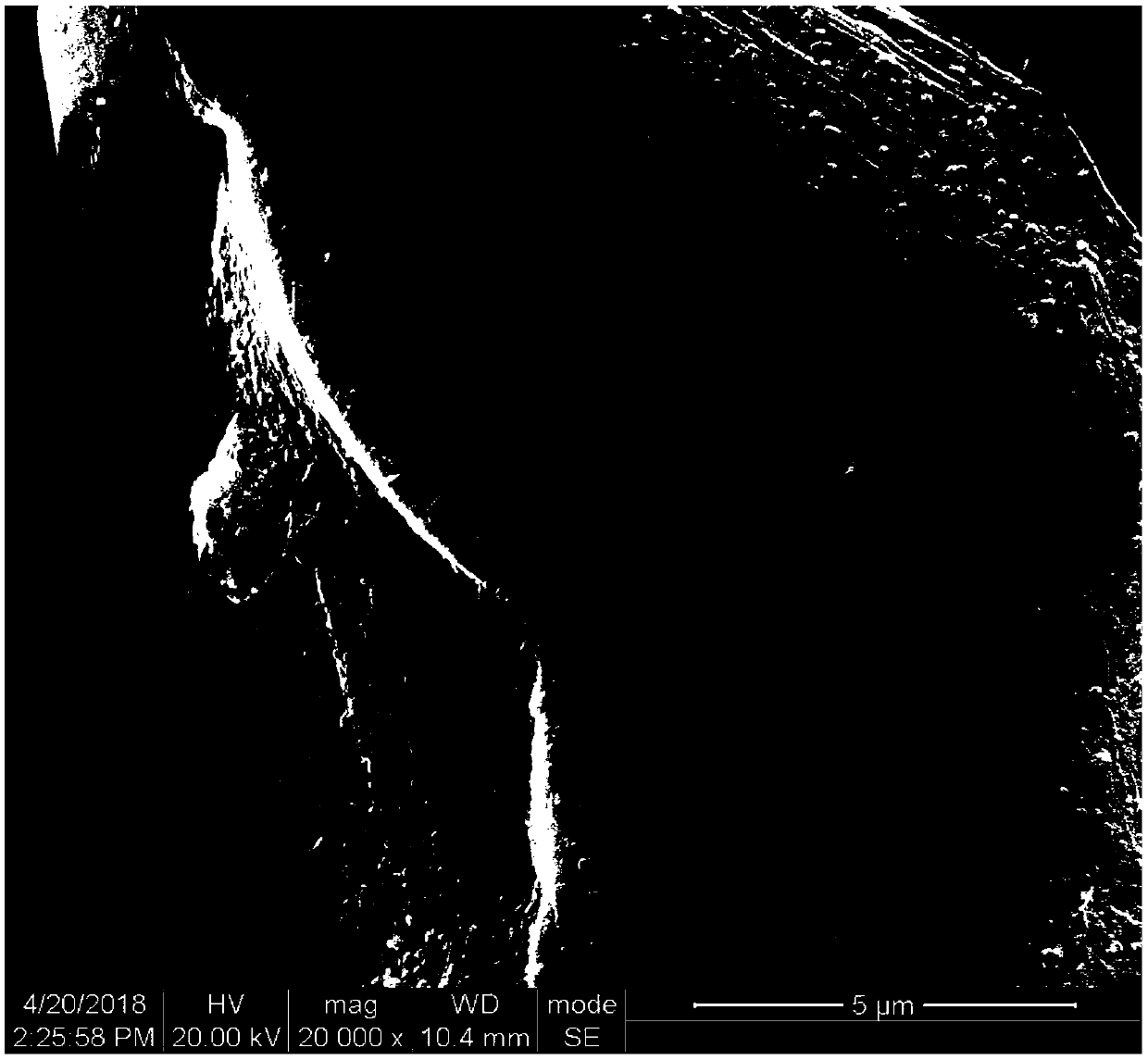

Image

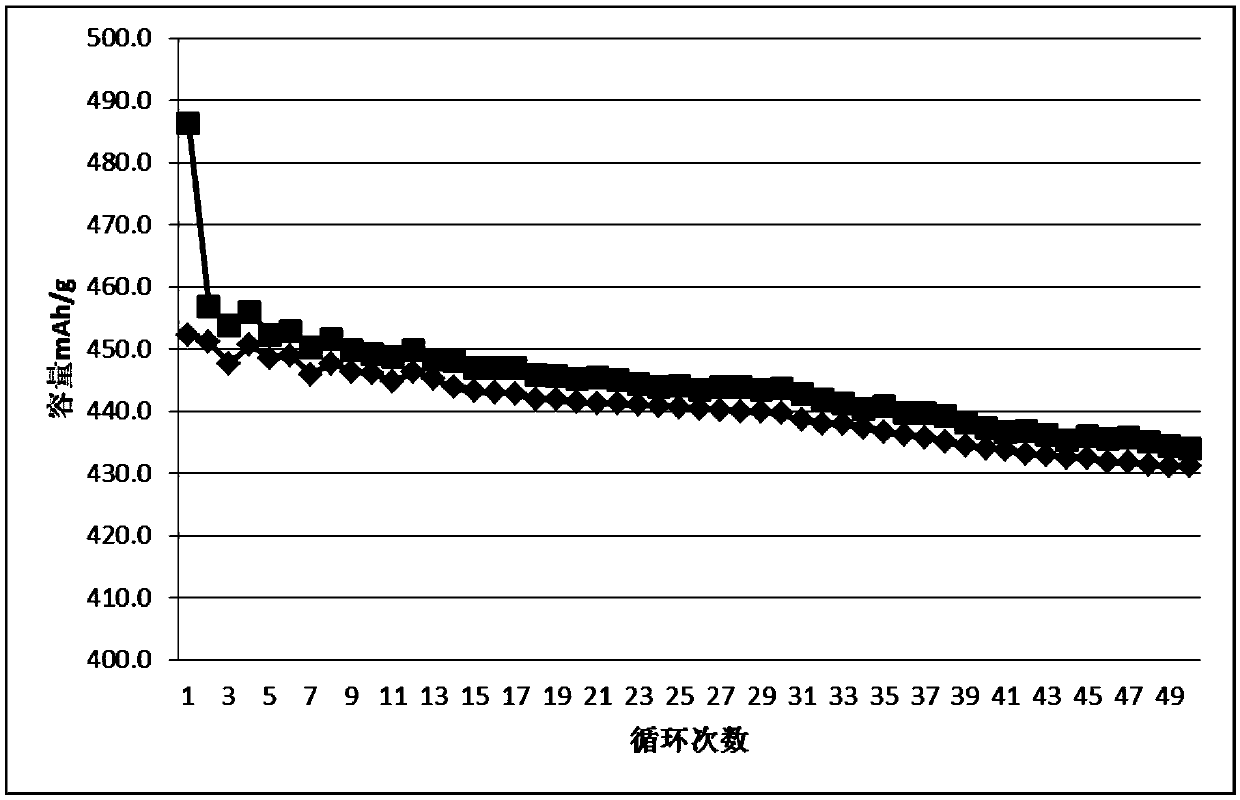

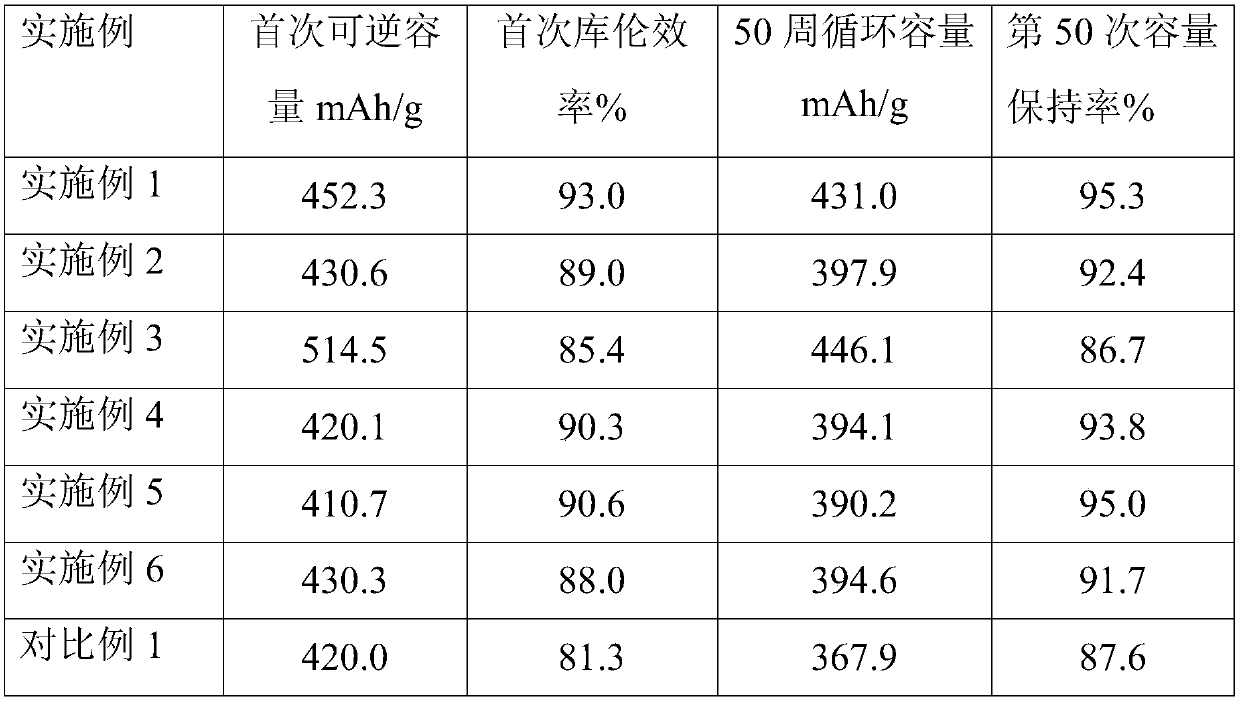

Examples

Embodiment 1

[0061] Sand-mill 3um coarse silicon in a 1:1 mixed solution of acetone and ethanol to a median particle size of 50nm, and control the solid content to 10% to prepare a nano-silicon slurry. Add the mixed dispersant of isobutanol and glyceryl monostearate with a mass ratio of 1:1 to the nano-silicon slurry at a mass ratio of dispersant: nano-silicon slurry of 3:100, and stir for 1 hour using a high-speed disperser at 1300RPM Added to the vacuum kneader. Then according to the mass ratio of nano-silicon: artificial graphite is 5:100; select carbon nanotubes with a median particle size of 80nm according to carbon nanotubes: nano-silicon / graphite mass ratio is 1:100; : The mass ratio of nano-silicon / graphite is 5:100; weigh the corresponding materials and add them to the vacuum kneader, heat to 250°C under vacuum (vacuum degree ≤ 0.085Mpa), mix and knead for 4 hours, cool to room temperature, and dry in a blast drying oven Dry at 85°C for 4 hours to obtain the precursor.

[0062] ...

Embodiment 2

[0065] Silicon powder with a median particle size of 50nm is dispersed in a mixed solution of acetone and ethanol with a mass ratio of 1:1 by stirring and ultrasonic, and the solid content is controlled at 10%. Add the mixed dispersant of isobutanol and glyceryl monostearate with a mass ratio of 1:1 to the nano-silicon slurry according to the mass ratio of dispersant: nano-silicon slurry of 3:100, and use a high-speed disperser at 1300RPM to stir and disperse for 1h Then add to the vacuum kneader. Then according to the mass ratio of nano-silicon: artificial graphite is 5:100; select carbon nanotubes with a median particle size of 80nm according to carbon nanotubes: nano-silicon / graphite mass ratio is 1:100; : The mass ratio of nano-silicon / graphite is 5:100; weigh the corresponding materials and add them to the vacuum kneader, heat to 250°C under vacuum (vacuum degree ≤ 0.085Mpa), mix and knead for 4 hours, cool to room temperature, and dry in a blast drying oven Dry at 85°C ...

Embodiment 3

[0068] Compared with Implementation 1, except that the mass ratio of nano-silicon:artificial graphite is 10:100, the silicon-carbon composite anode material is prepared under the same process conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com