Carbon-containing material and lithium secondary cell containg the same material

A polymer material and conductive carbon technology, applied in battery electrodes, transportation and packaging, circuits, etc., can solve the problems of poor cycle characteristics, low charge-discharge efficiency, low conductivity, etc., to prevent cycle efficiency from getting worse, Improved charge-discharge capacity and improved charge-discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

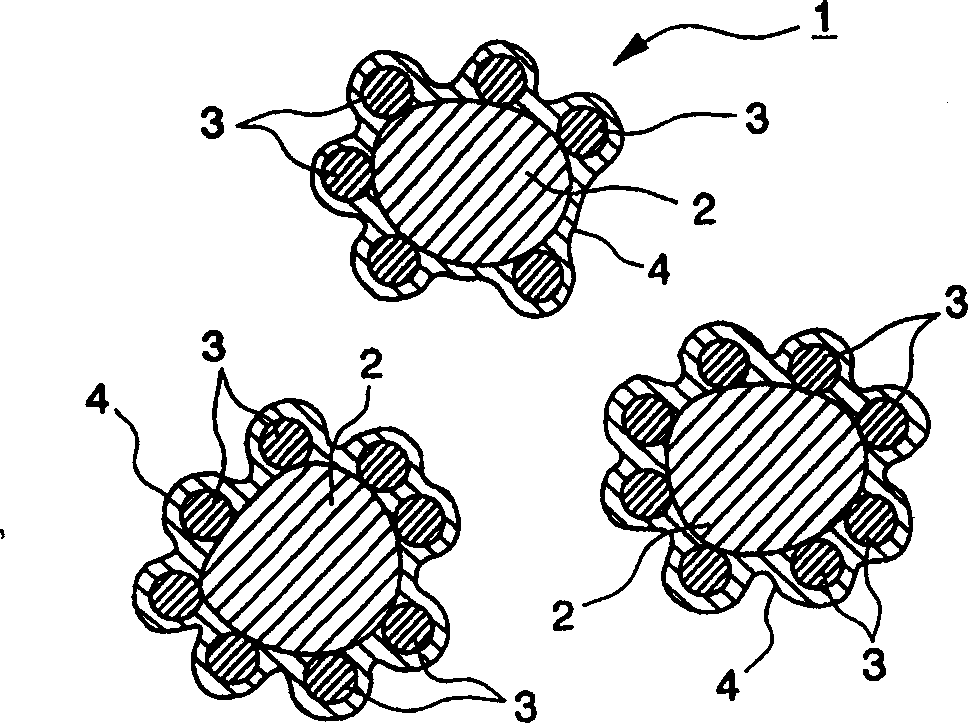

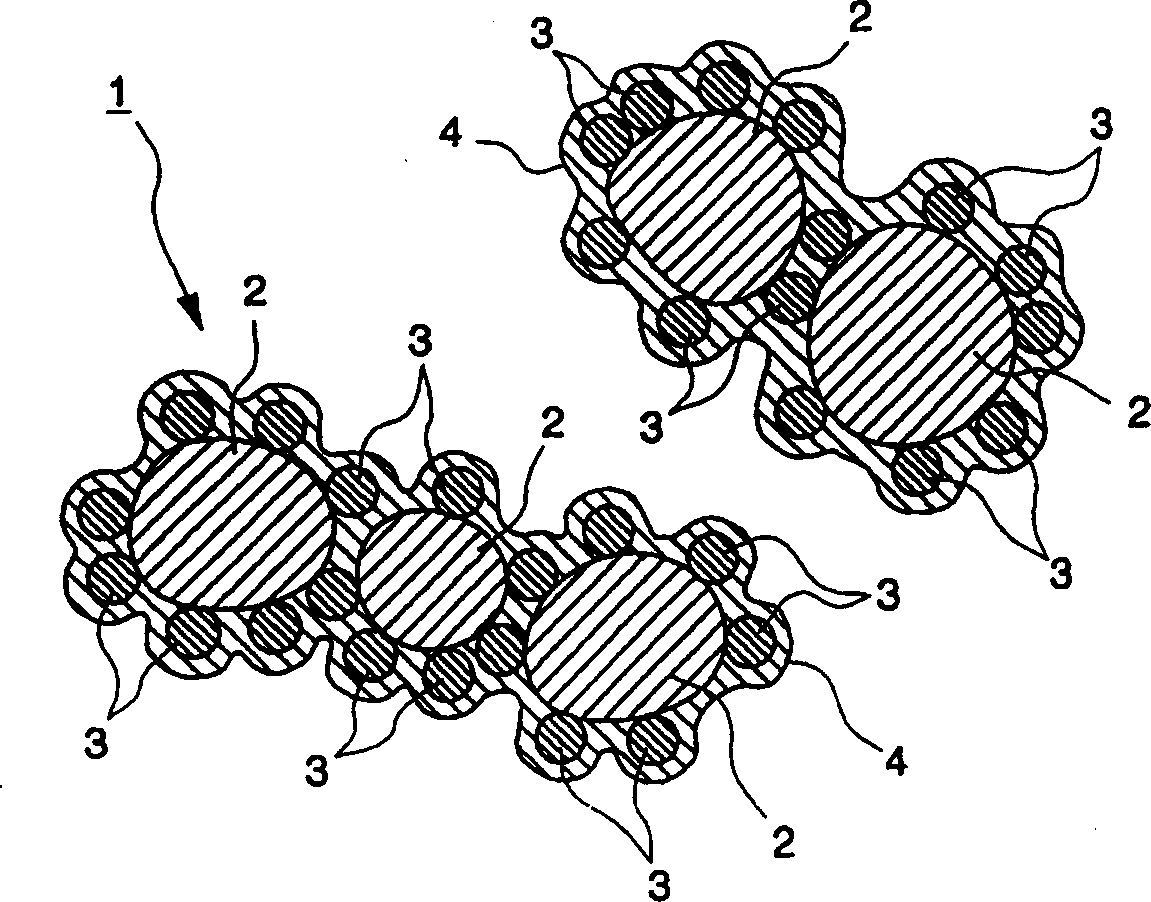

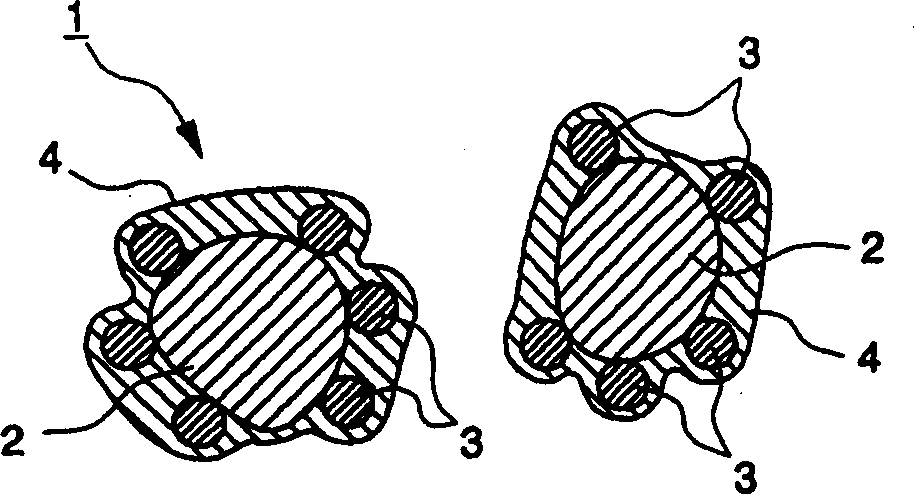

[0144] 2 parts by weight of Si particles having an average particle size of 390 nm were mixed with 1 part by weight of carbon black. Si particles are mainly composed of crystalline silicon, and the resistivity of carbon black is 10 -4 Ω·m.

[0145] 10 parts by weight of the phenolic resin was dissolved in isopropyl alcohol to prepare a solution. A mixture of Si particles and carbon black was added to the solution and stirred well, and then the solvent was removed to obtain a composite particle precursor in which carbon black and a phenolic resin layer were attached to the surface of the Si particles.

[0146] The composite particle precursor was heated at 1000° C. for 180 minutes in an argon (Ar) atmosphere to carbonize the phenolic resin layer, thereby forming a 0.05 μm thick hard carbon layer on the composite particle surface.

[0147] According to the flexible strength of carbonized material is about 800kg / cm 2 In fact, when the phenolic resin itself is carbonized under ...

Embodiment 2

[0153] The carbonaceous material was prepared in the same manner as in Example 1, except that the average particle size of the Si particles was 700 nm.

Embodiment 3

[0155] The carbonaceous material was prepared in the same manner as in Example 1, except that the average particle size of the Si particles was 1060 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com