Patents

Literature

35results about How to "Strong electrical signal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick film conductor composition for use in biosensors

InactiveUS6599408B1Improve electrocatalytic activityStrong electrical signalImmobilised enzymesBioreactor/fermenter combinationsElectrical conductorCombined use

The invention is directed to polymer thick film conductor compositions comprising conductive metal particles selected from the group consisting of finely divided powders of platinum group metals and mixtures thereof or metallized graphite particles; in combination with a thermoplastic polymer and optionally, graphite conductive filler.

Owner:DUPONT ELECTRONICS INC

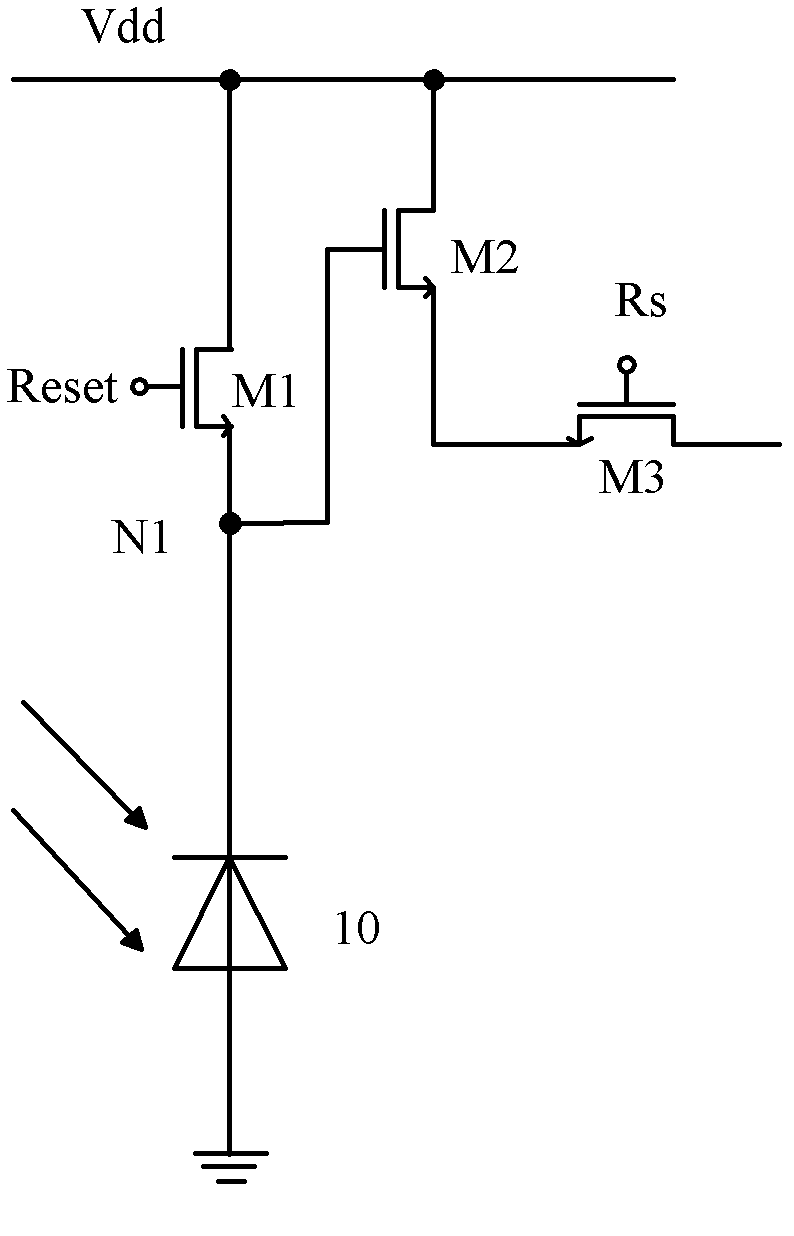

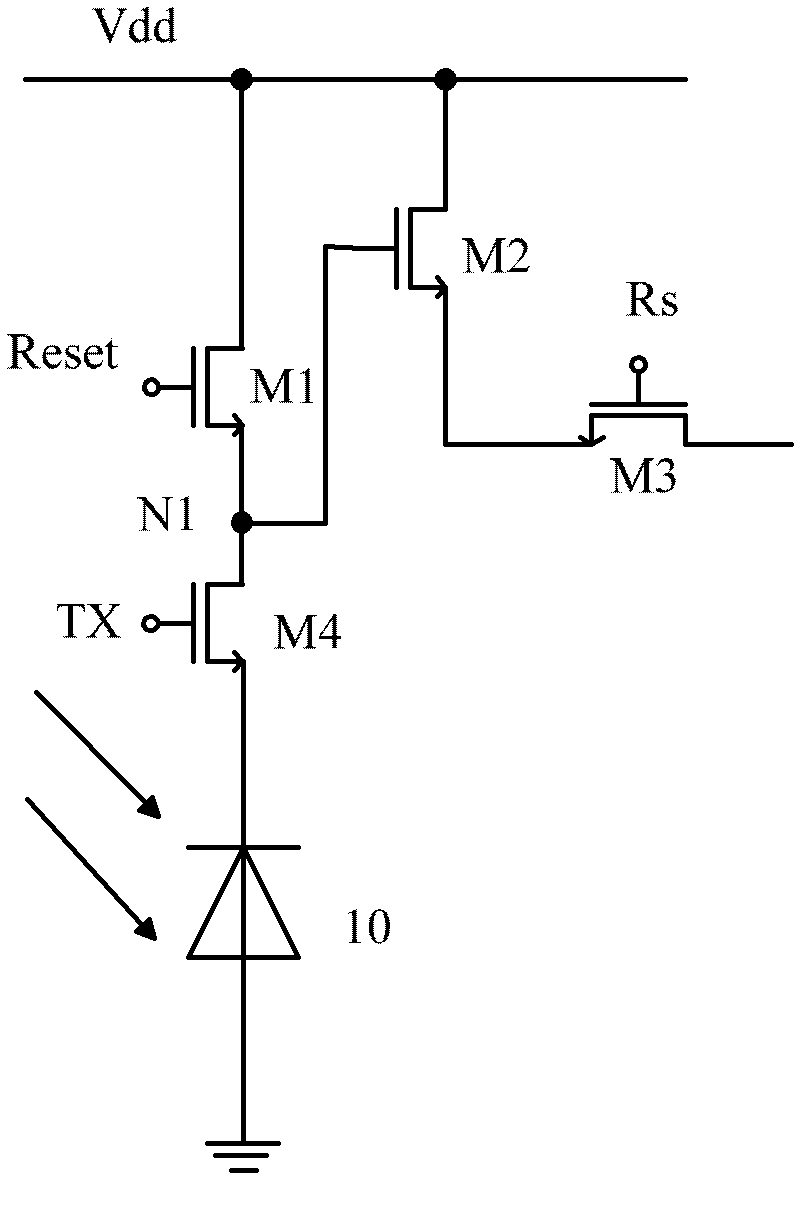

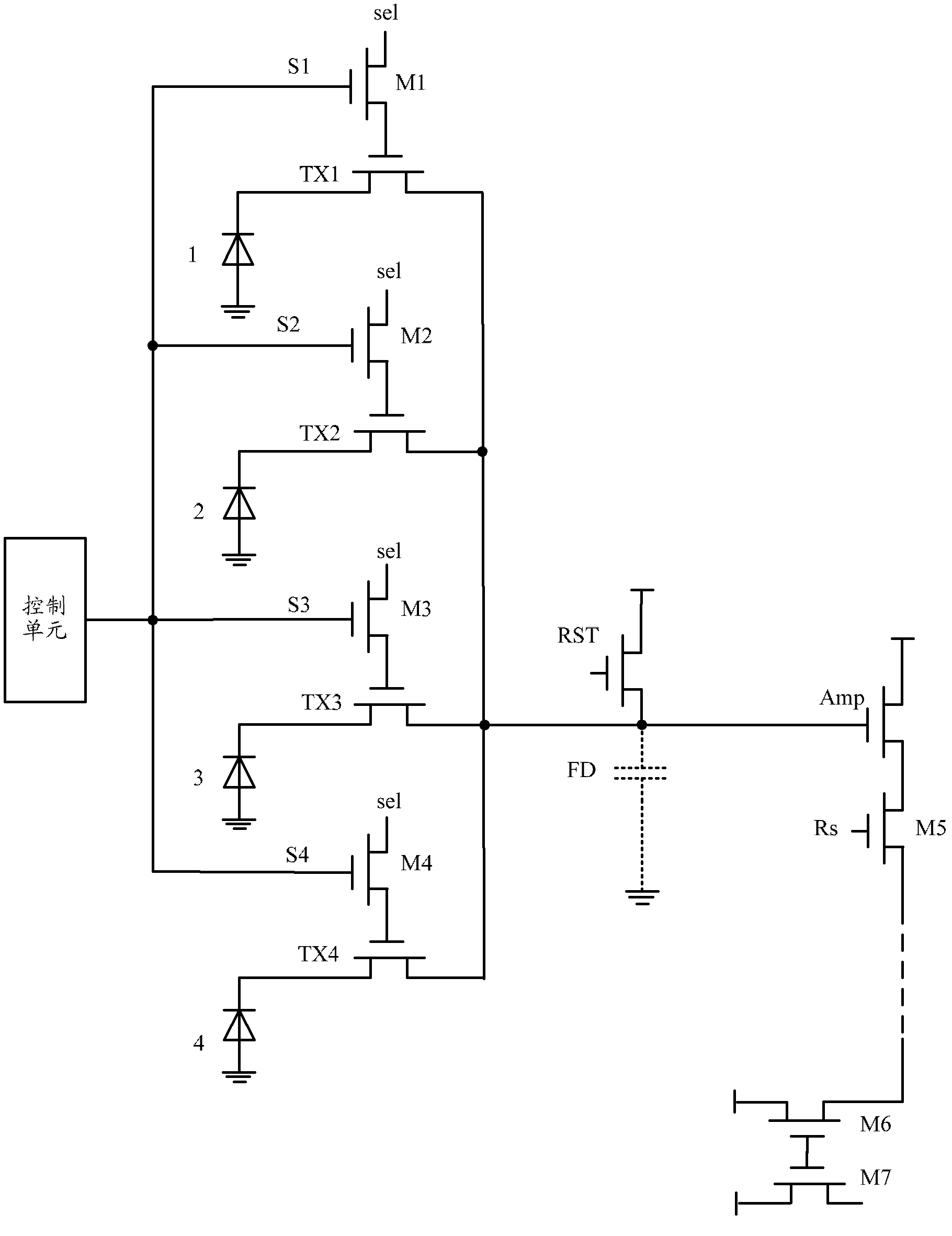

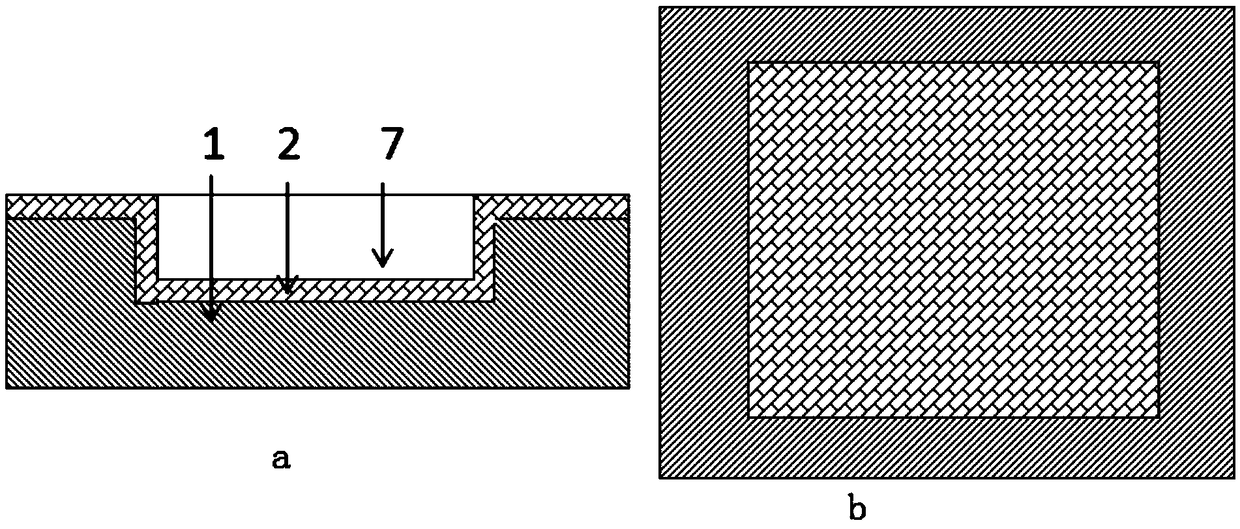

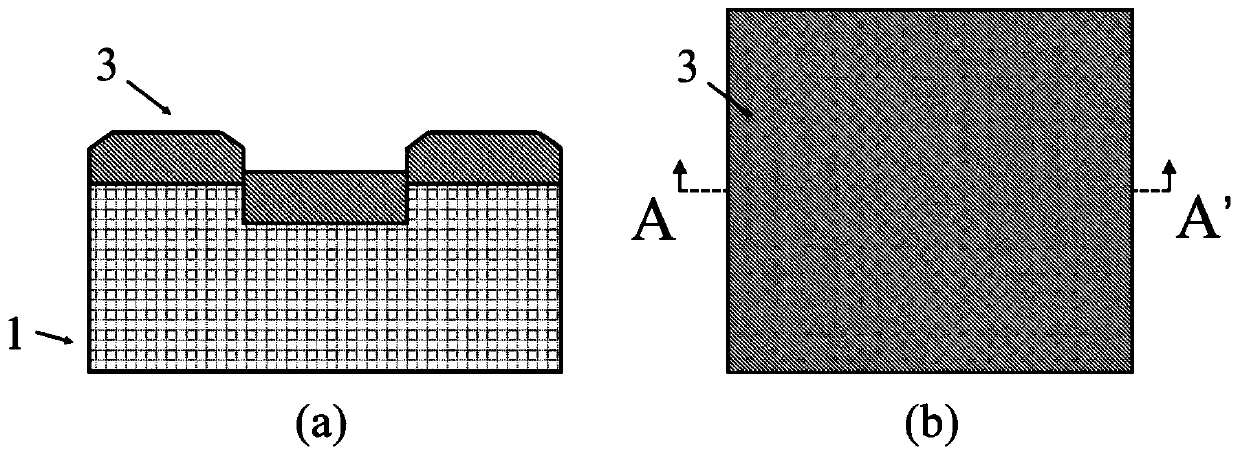

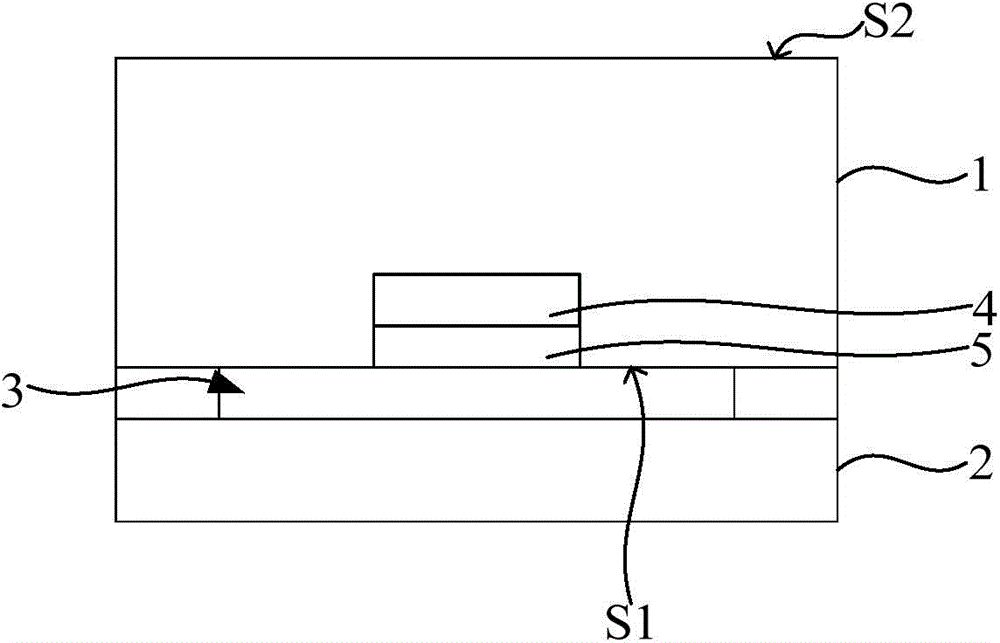

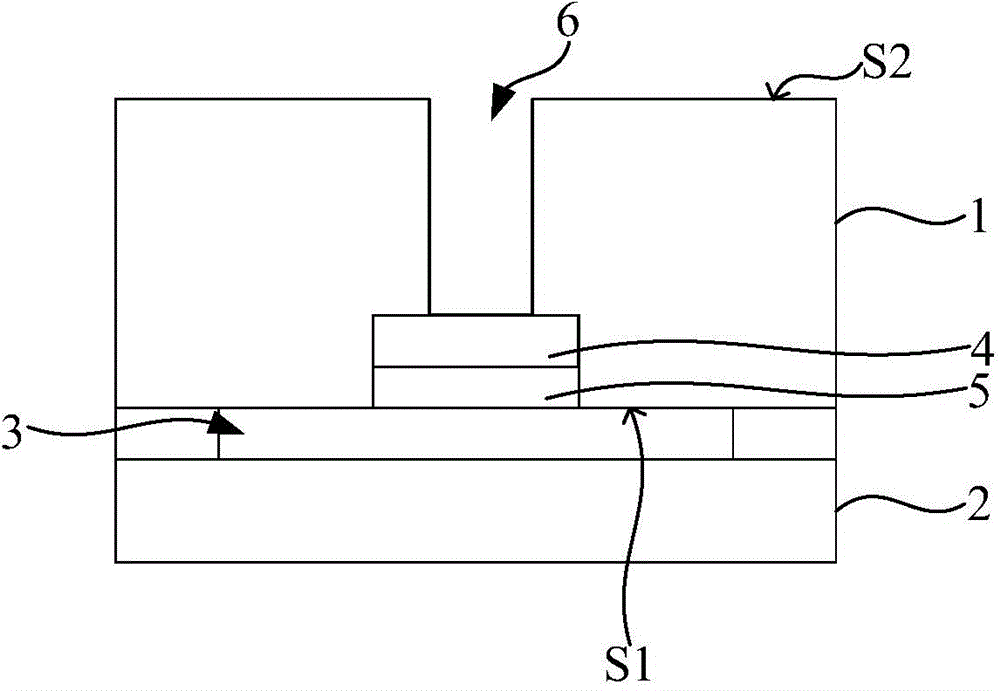

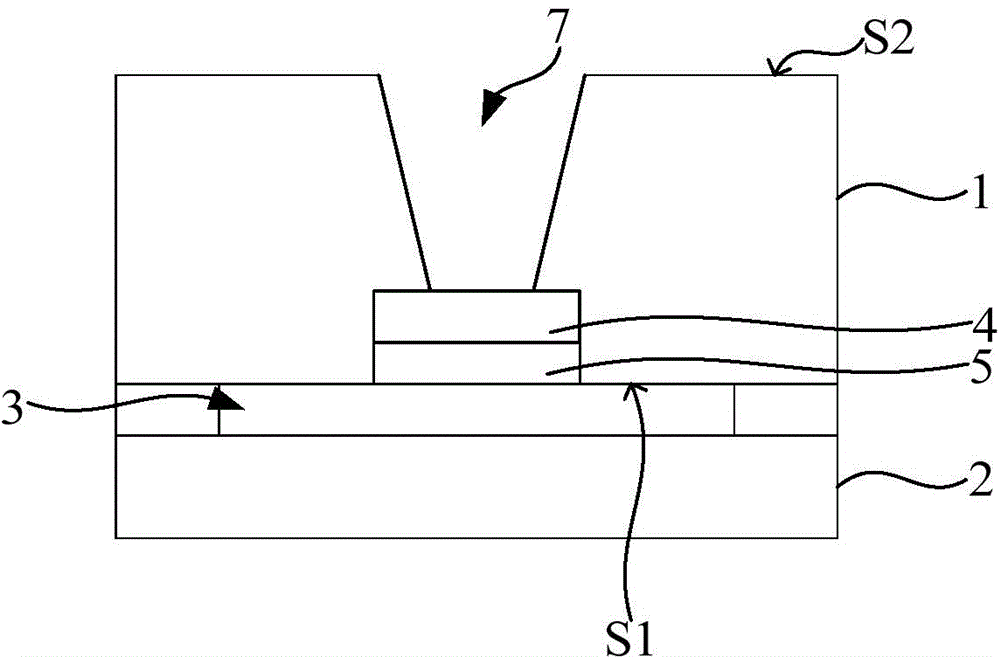

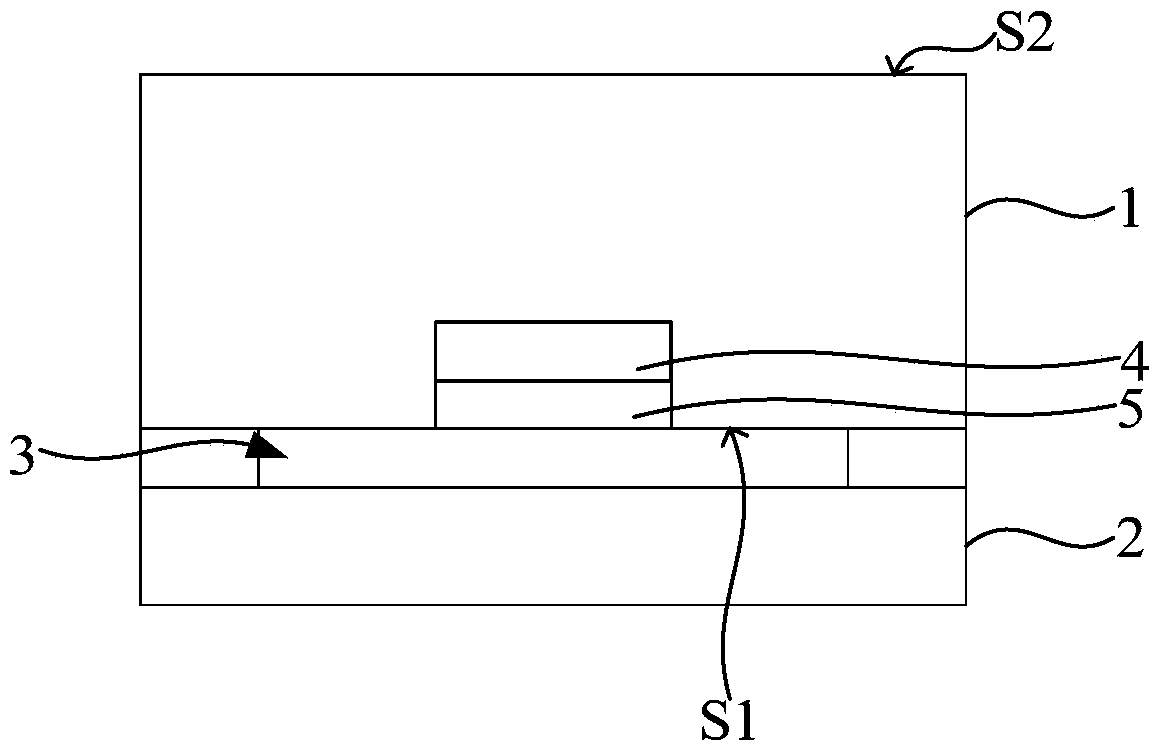

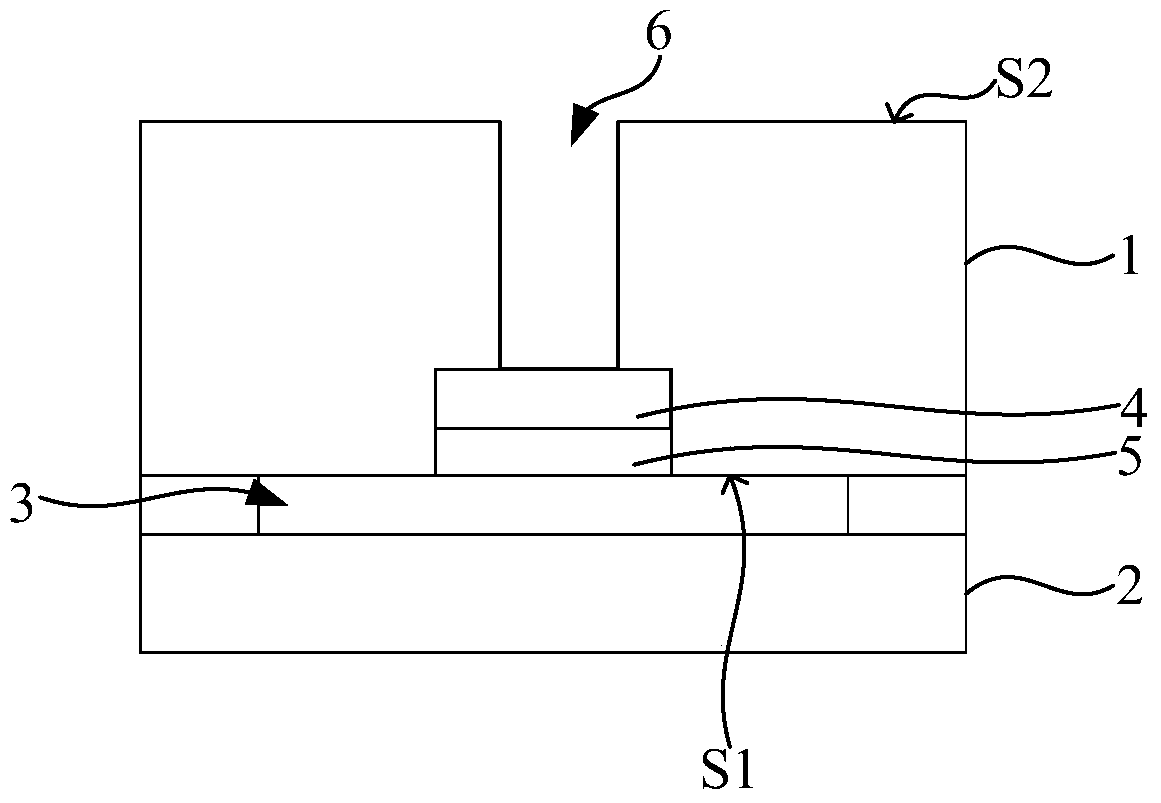

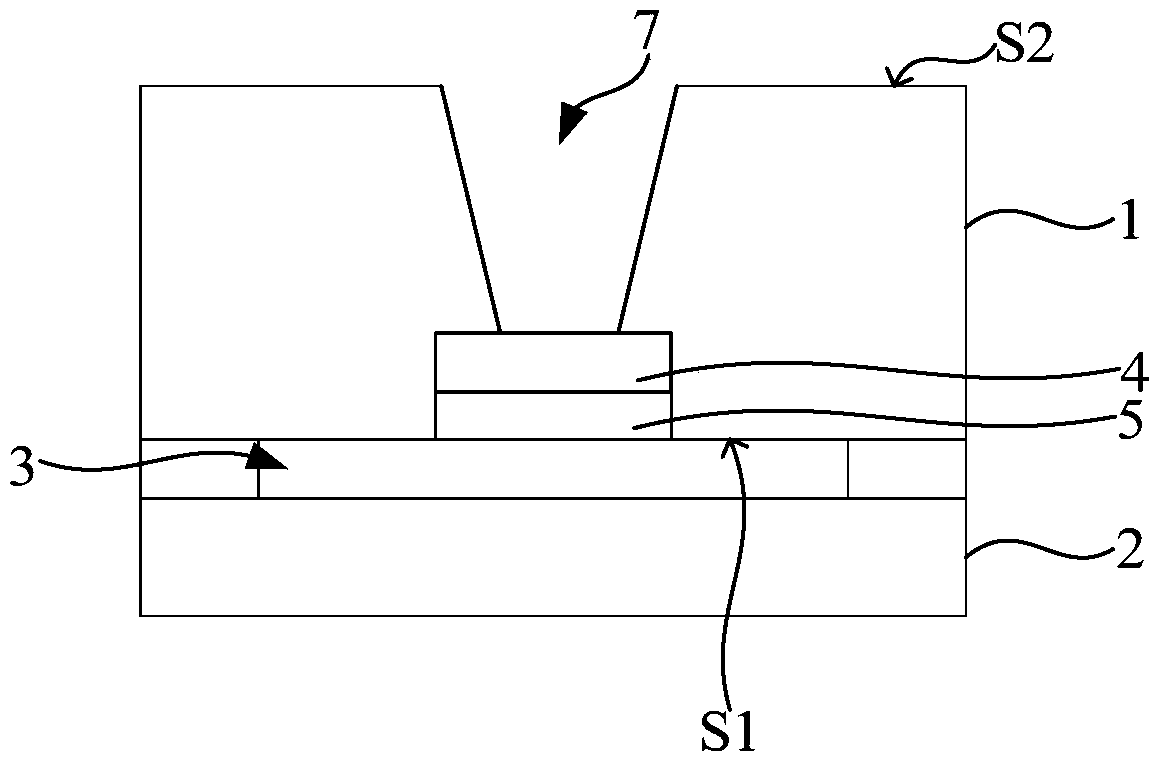

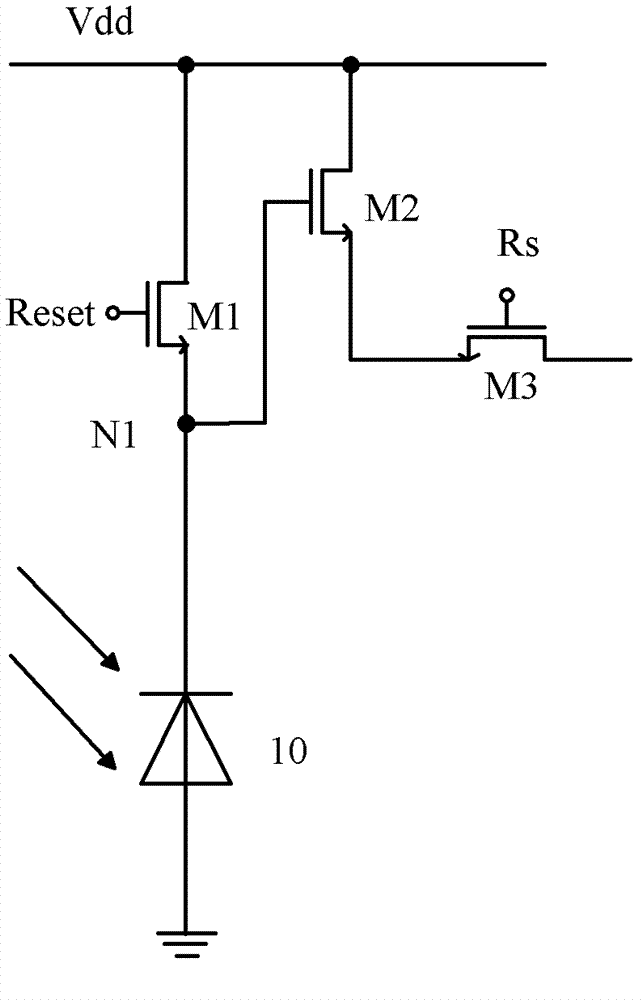

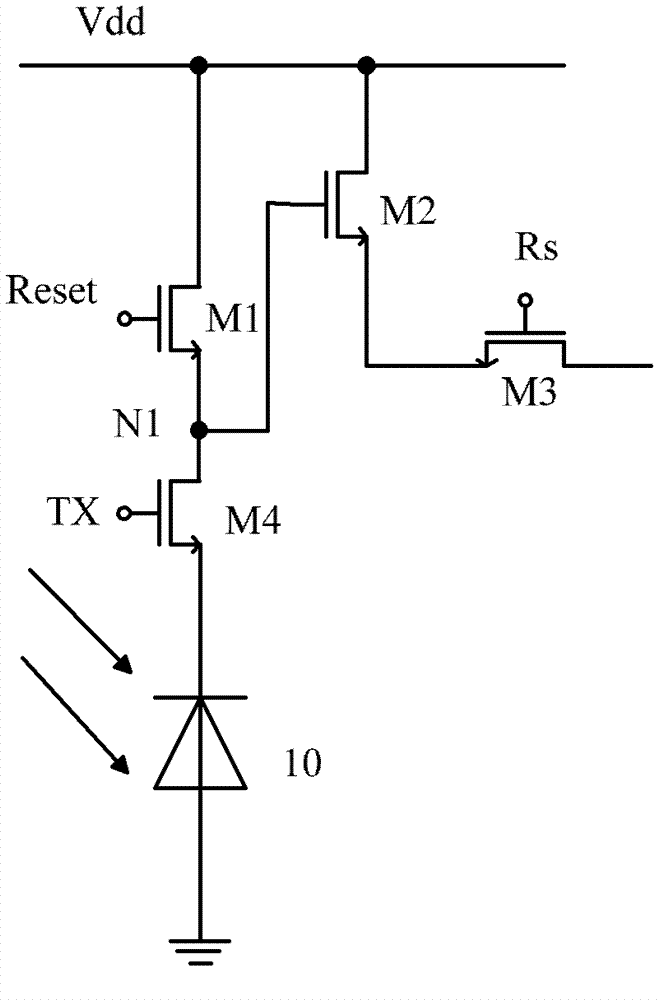

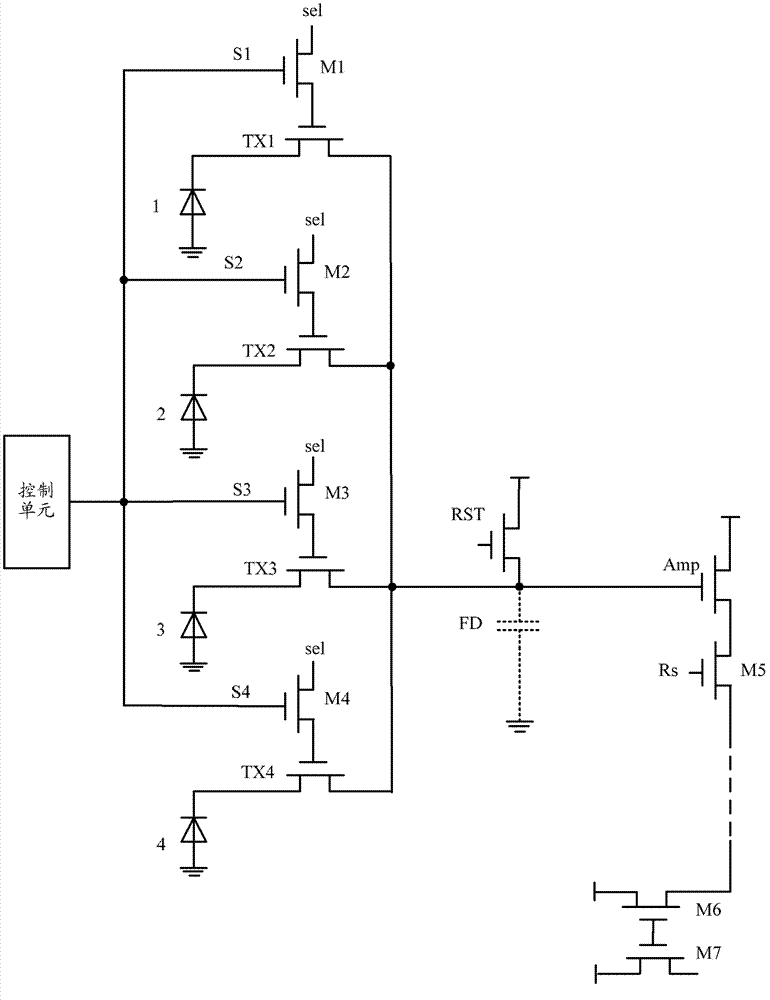

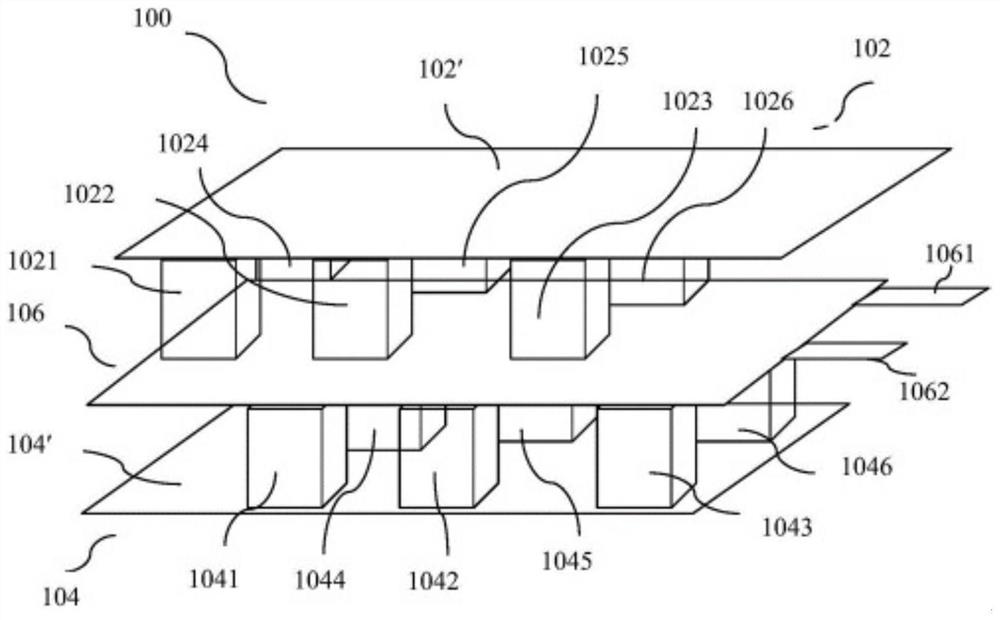

Wide-dynamic range image sensor and control method thereof

ActiveCN102547159AWork fasterReduce total operating timeTelevision system detailsColor television detailsFloating diffusionWide dynamic range

The invention relates to the field of image sensors, and discloses a wide-dynamic range image sensor and a control method thereof. According to the invention, a plurality of photoreceptors and a plurality of transfer transistors are arranged in each pixel; in each integration period, the photoreceptors are sequentially connected with a floating diffusion area according to a preset time sequence respectively, the photoreceptors are sequentially read, and the other photoreceptors are integrated in the reading process of a certain photoreceptor, so that concurrent integration can shorten total operation time and increase the operating speed of the image sensor in a wide-dynamic range operating mode; and a structure with two layers of micro lenses is adopted, so that each photoreceptor in the same pixel can sample optical signals of the same point, and the optical signal detection accuracy of the image sensor is improved.

Owner:重庆子丘软件有限公司

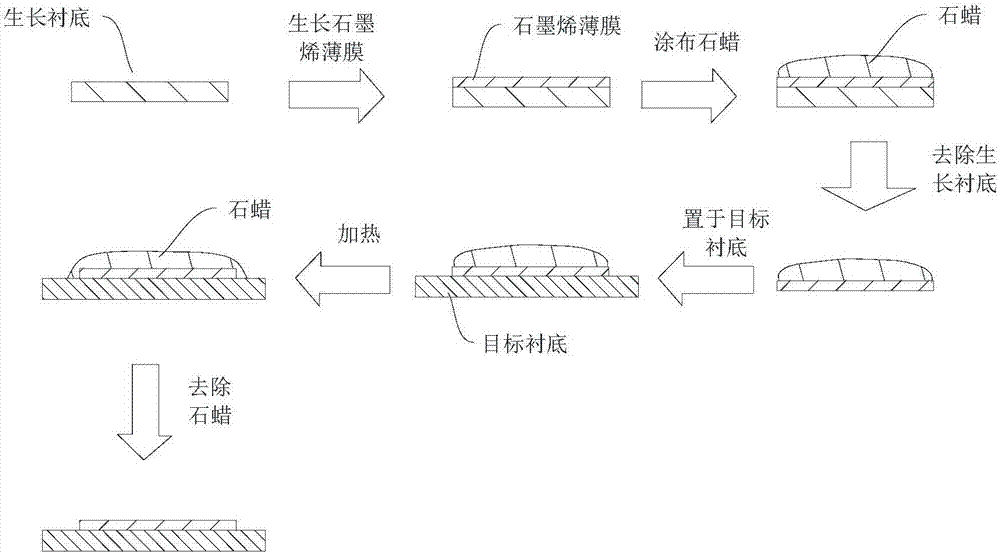

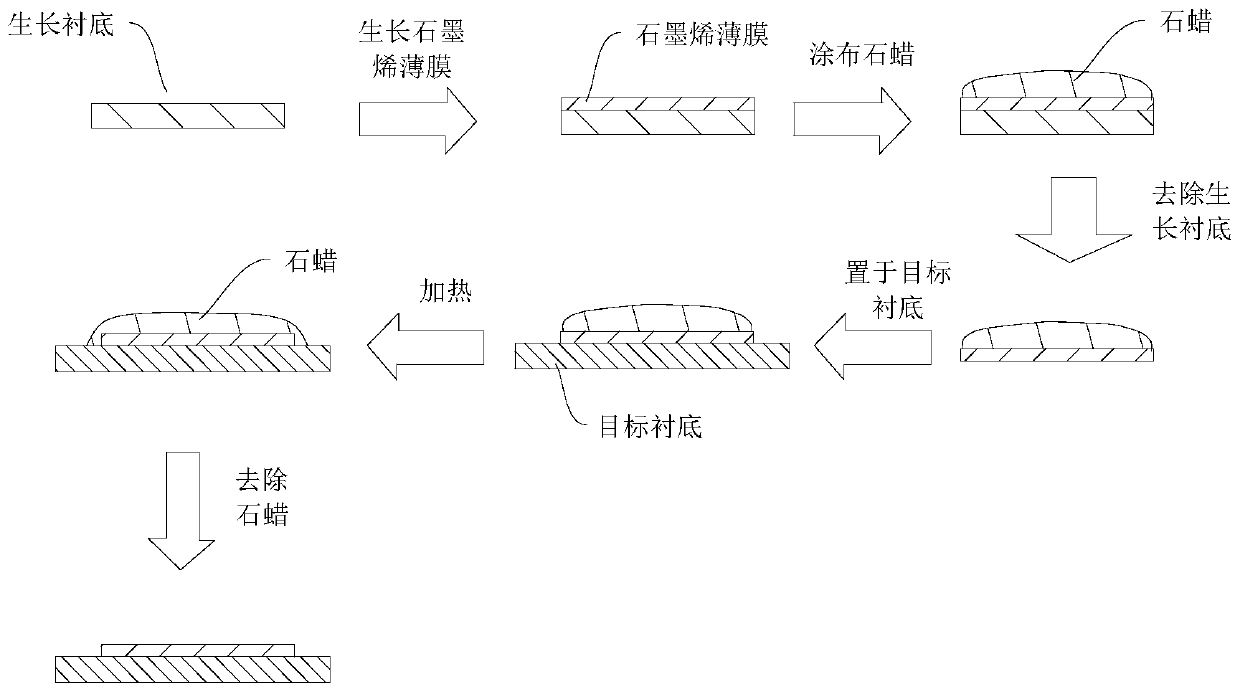

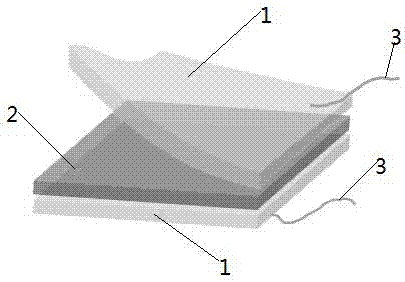

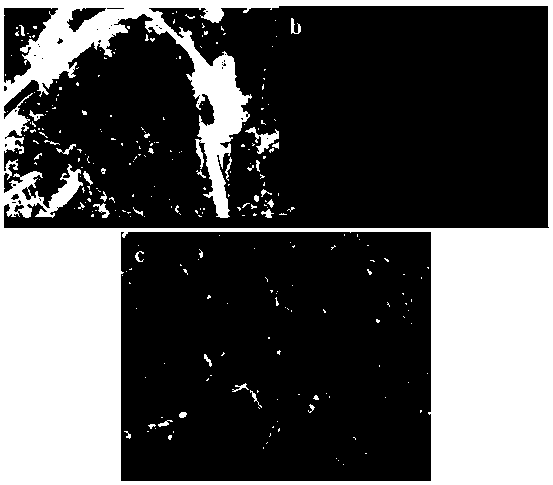

Novel graphene thin film transferring method and preparation method of sensor

InactiveCN106946248ATransfer losslessReduce the difficulty of operationCarbon compoundsConverting sensor output electrically/magneticallyParaffin waxComposite film

The invention provides a novel graphene thin film transferring method and a preparation method of a sensor and relates to the technical field of graphene. The novel graphene thin film transferring method comprises the following steps: covering melted paraffin wax on the surface of a graphene thin film which is formed on the surface of a growth substrate; after the paraffin wax is cured, removing the growth substrate to obtain a paraffin wax / graphene composite thin film; putting the paraffin wax / graphene composite thin film on the surface of a target substrate; heating the target substrate until the paraffin wax is fitted to the target substrate and removing the paraffin wax by utilizing a solvent. The method provided by the invention takes the paraffin wax as a novel transferring medium and is convenient to operate; and the graphene thin film can be basically transferred in a lossless manner. The preparation method of the sensor comprises the following steps: a channel electrode is manufactured on the surface of the graphene thin film prepared using the transferring method and a pattern of a touch sensor is formed by the graphene thin film; and an optical adhesive is fitted on the surface of the graphene thin film and then de-foaming treatment is carried out. By adopting the method provided by the invention, the obtained graphene thin film is complete, basically has no loss and has large area, and can be used for manufacturing the sensor.

Owner:成都川烯科技有限公司

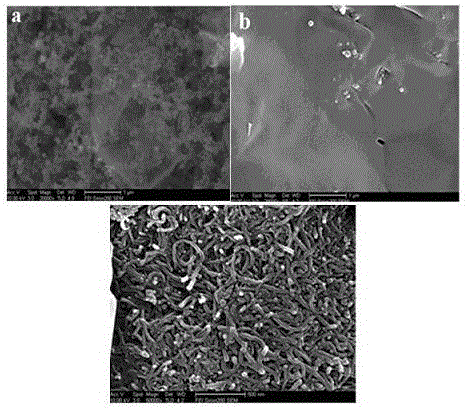

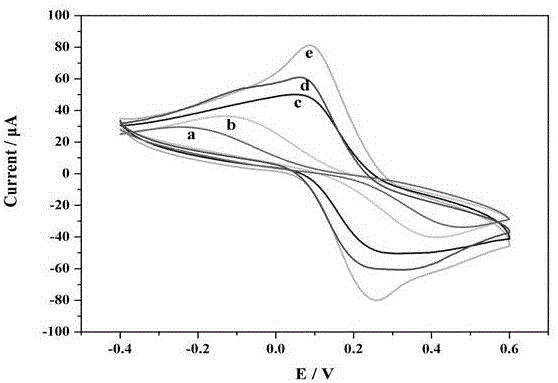

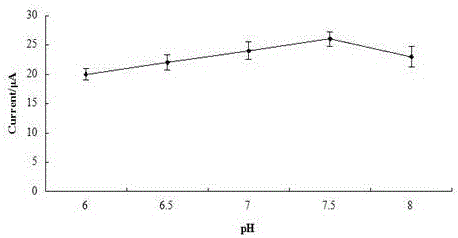

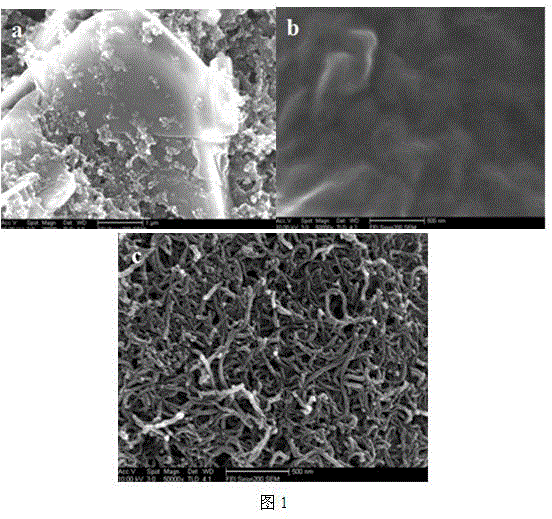

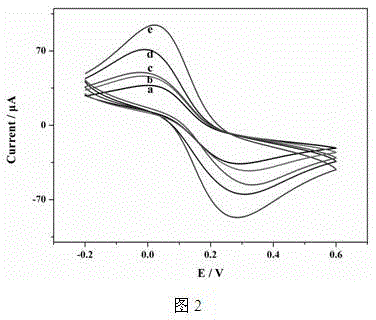

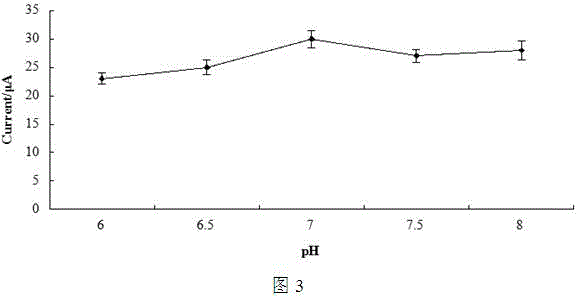

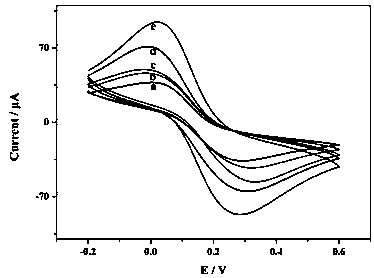

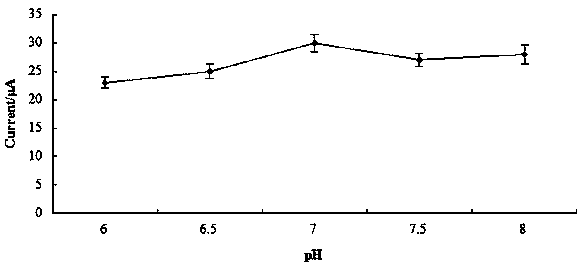

Silk-screen printing electrode sensor preparation method based on ionic liquid-multi-wall carbon nano-tube modification

InactiveCN105021679AIncreased current responseFlexible designMaterial nanotechnologyMaterial analysis by electric/magnetic meansScreen printingPesticide residue

The present invention discloses a silk-screen printing electrode sensor preparation method based on ionic liquid-multi-wall carbon nano-tube modification, and belongs to the technical field of biological sensors. According to the method, an ionic liquid-multi-wall carbon nano-tube nanometer material is prepared and then coats the surface of a silk-screen printing carbon electrode in a dropwise manner, and then acetylcholine esterase coats the surface of the ionic liquid-multi-wall carbon nano-tube nanometer material modified silk-screen printing work electrode in a dropwise manner so as to prepare the acetylcholine esterase biological sensor for detecting organic phosphorus and carbamate pesticides. According to the present invention, the prepared sensor has characteristics of simple process, easy operation, low cost, high detection sensitivity, strong electrical signal and simple electrode pretreatment, and is suitable for detection of pesticide residues, wherein the detection limit is 0.05 [mu]g / L.

Owner:SHANDONG UNIV OF TECH

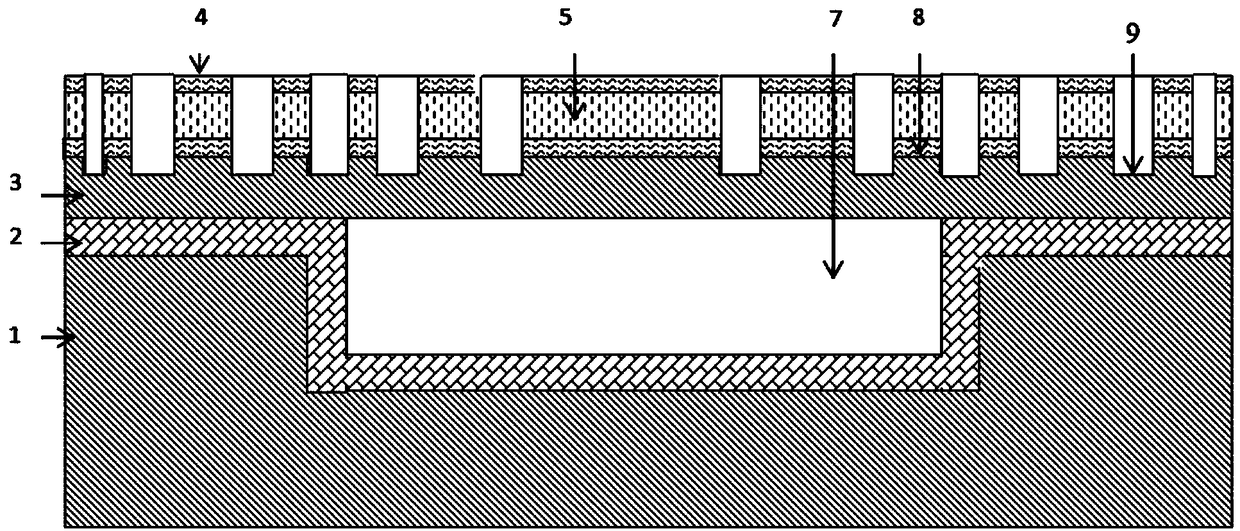

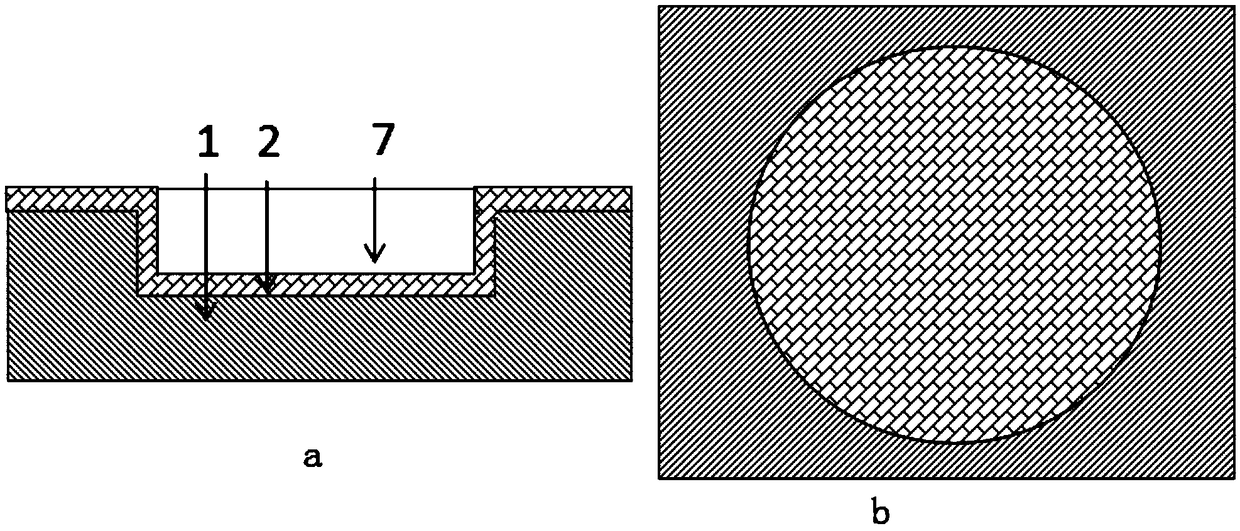

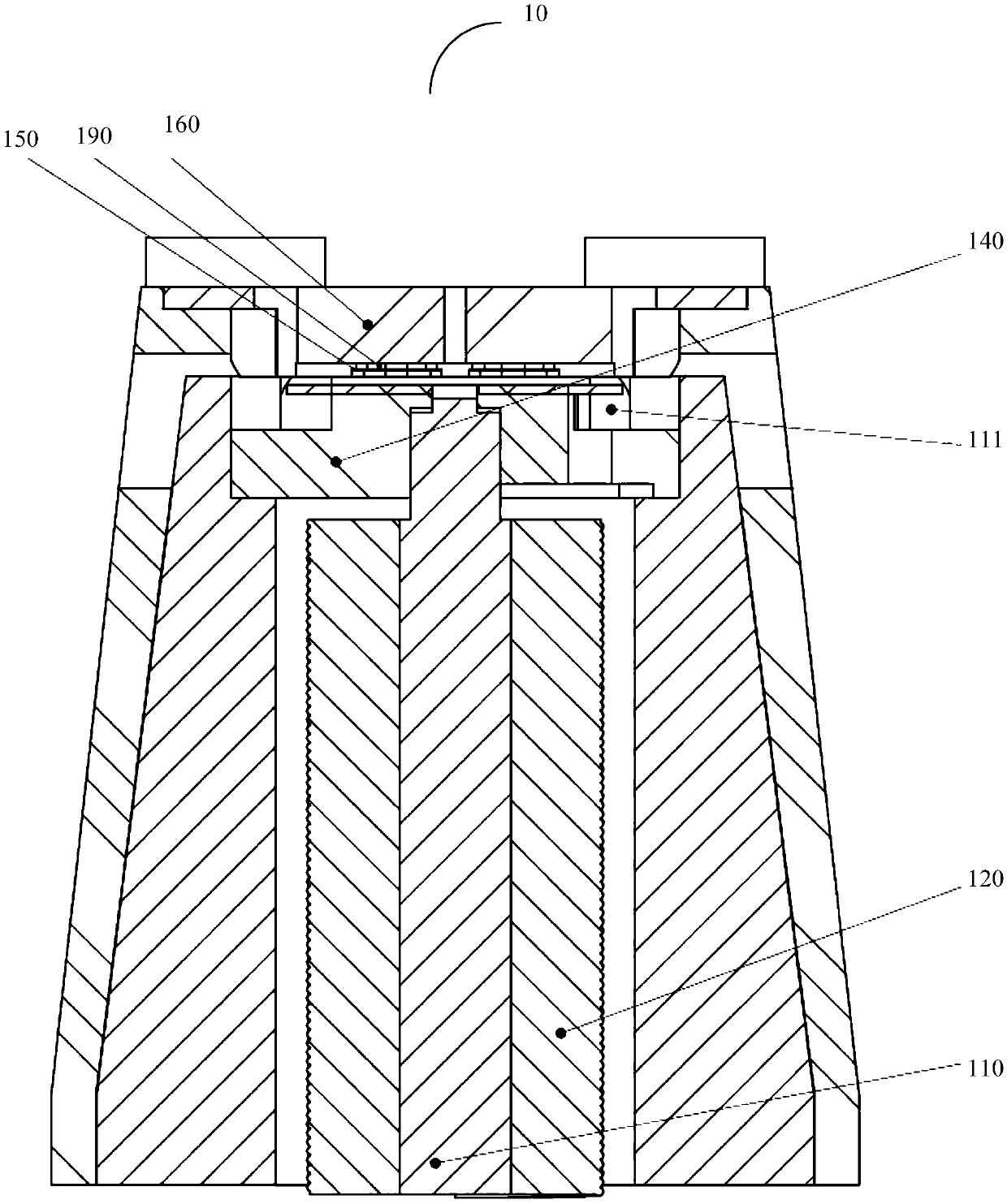

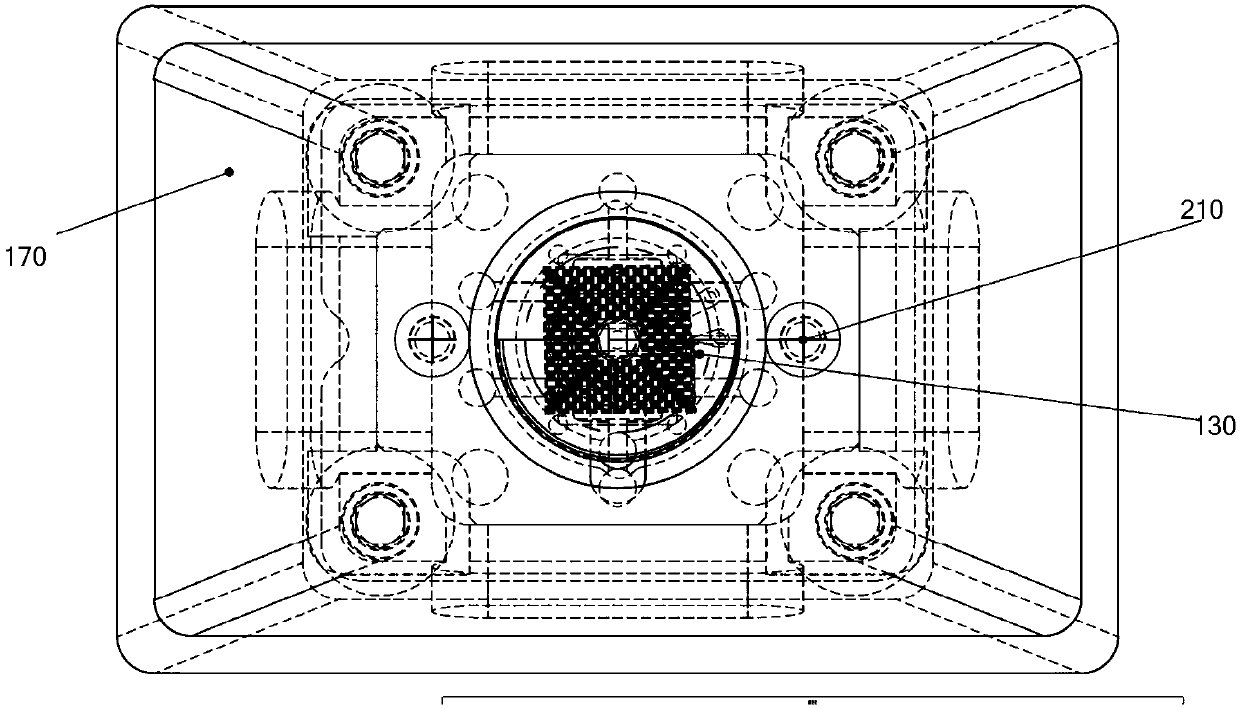

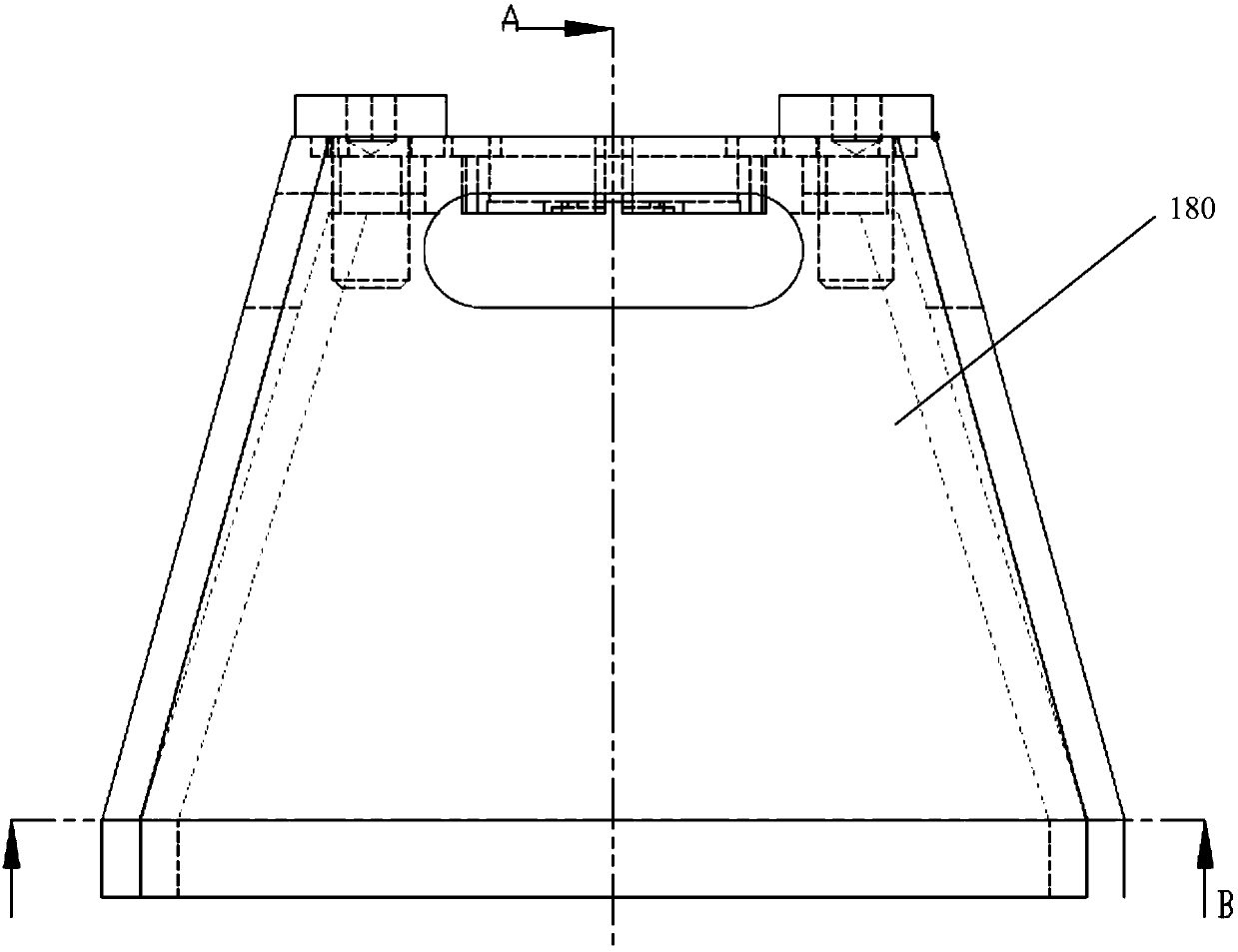

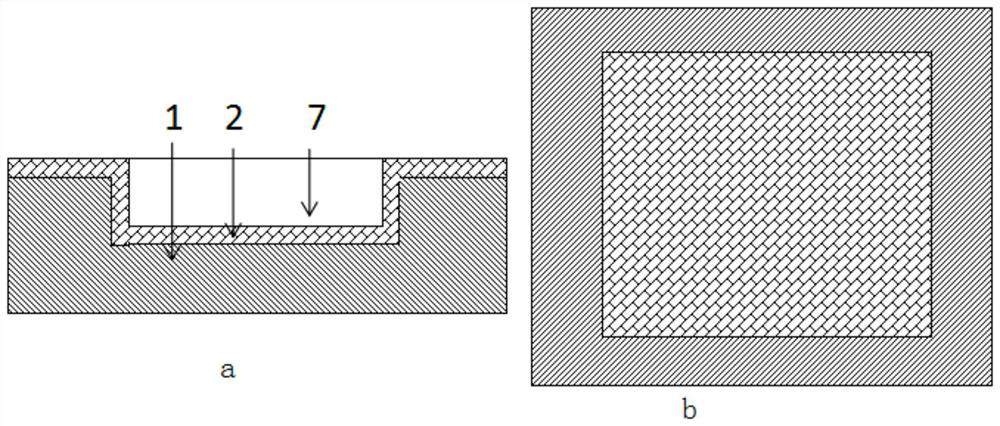

Piezoelectric microphone with high sensitivity as well as production method

ActiveCN109511023AIncrease vibration displacementIncreased strain stressMouthpiece/microphone attachmentsElectricityInter layer

The invention discloses a piezoelectric microphone with high sensitivity as well as a production method. The piezoelectric microphone comprises a base provided with a cavity and a piezoelectric stacking structure arranged on the base, the cavity in the base is a vacuum vibration cavity, the piezoelectric stacking structure sequentially comprises a bottom electrode, a piezoelectric film and a top electrode, and the base comprises a base bottom layer, a base intermediate layer and a base top layer. The production method comprises the following steps: firstly etching the cavity in the base bottomlayer, then depositing the base intermediate layer, then bonding the base top layer on the base intermediate layer in a vacuum environment, so as to form a vibration cavity, then etching an annular groove on the base top layer, depositing a sacrificial layer in the annular groove, then sequentially depositing the bottom electrode, the piezoelectric film and the top electrode on the base top layer, forming a corrosion hole in the top electrode, and corroding off the sacrificial layer, so that production of the piezoelectric microphone is completed. The piezoelectric microphone disclosed by theinvention can guarantee a vacuum state inside the cavity, air resistance does not exist, strain stress of the piezoelectric film is greatly improved, and a stronger electrical signal is output.

Owner:武汉敏声新技术有限公司

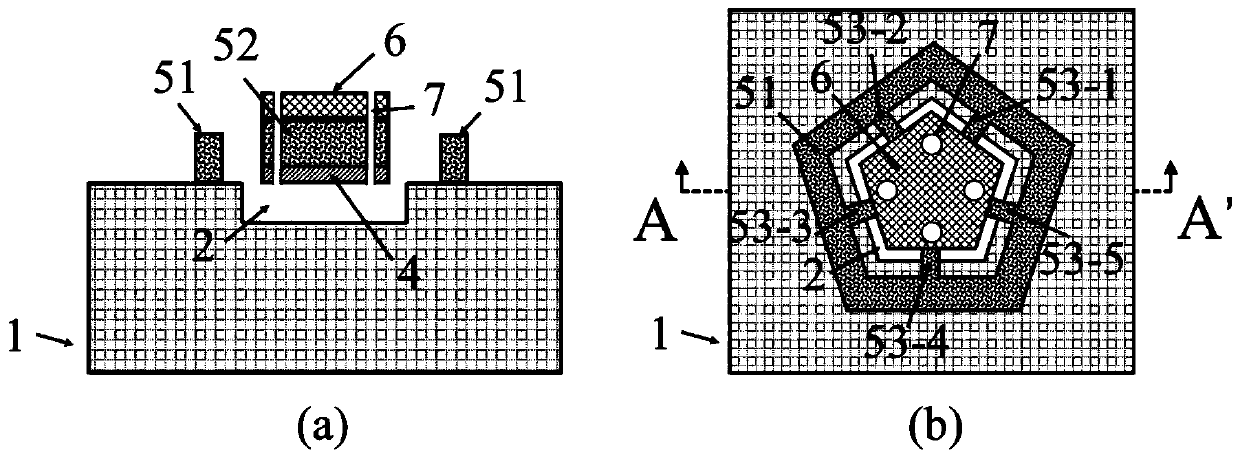

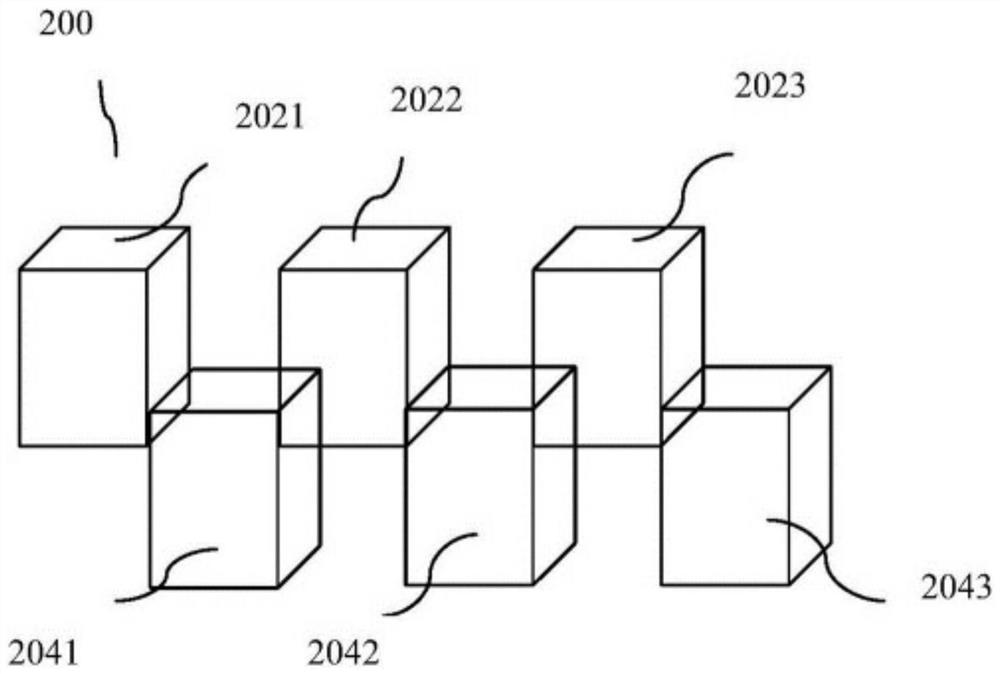

Film bulk acoustic resonator and preparation method thereof

ActiveCN111010127AImprove performanceVibration freeImpedence networksThin-film bulk acoustic resonatorThin membrane

The invention discloses a film bulk acoustic resonator and a preparation method thereof. The film bulk acoustic resonator comprises a substrate, a cavity and a piezoelectric stack structure, the piezoelectric stack structure sequentially comprises a bottom electrode, a piezoelectric material layer and a top electrode from bottom to top; the piezoelectric material layer is composed of a piezoelectric material effective area, a piezoelectric material outer area and an anchor. The effective area of the piezoelectric material is smaller than the cavity area. The edge of the effective area of the piezoelectric material contacts with air and is connected with the outer area of the piezoelectric material through an anchor. The effective area of the piezoelectric material is suspended above the cavity through the support of the anchor; during resonance, sound waves transversely propagating in the effective area of the piezoelectric material are reflected by air at the edge, in addition, duringresonance, only vibration of the working area of the piezoelectric stack structure is bound by anchors, the piezoelectric stack structure can vibrate more freely, stronger electric signals are generated while clutter influences are reduced, and therefore the performance of the film bulk acoustic resonator is improved.

Owner:武汉敏声新技术有限公司

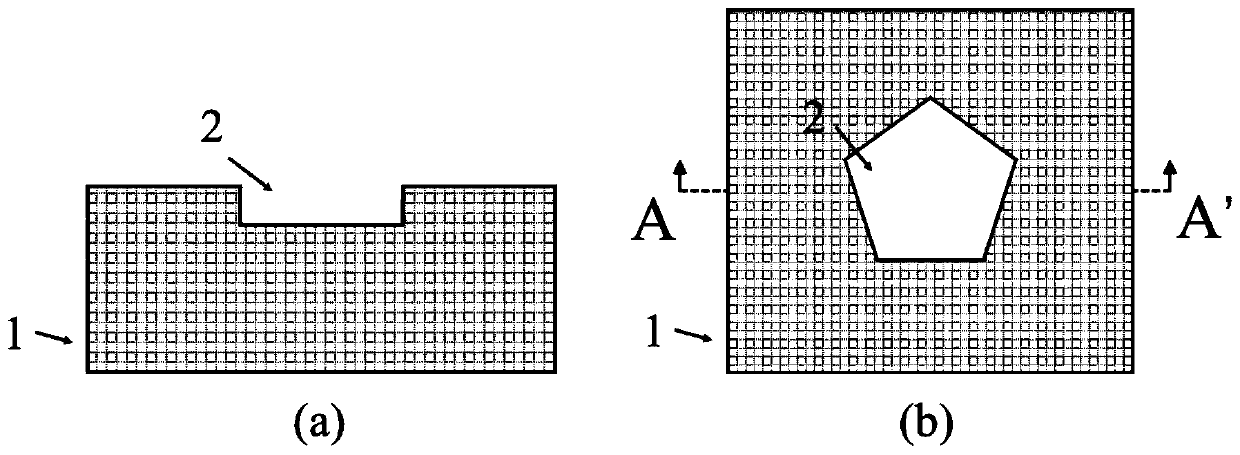

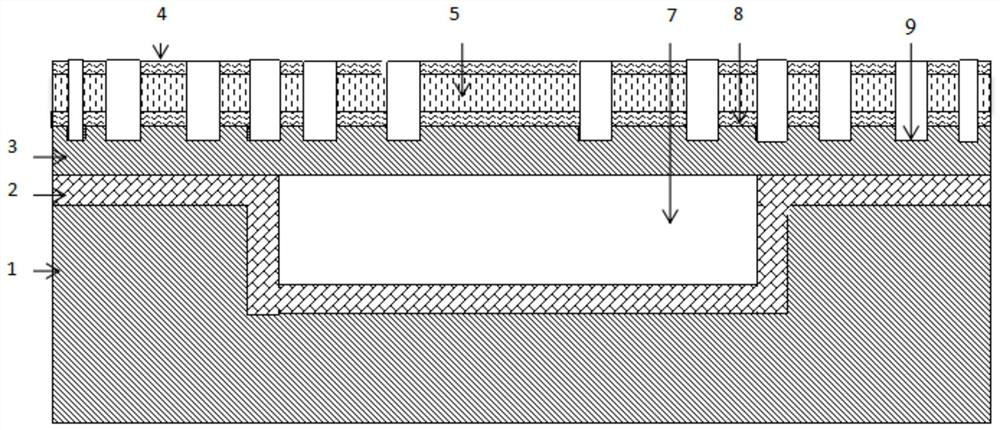

Wafer level packaging method

ActiveCN104617033AStrong electrical signalImprove performanceSemiconductor/solid-state device manufacturingEXPOSEWafer-level packaging

The invention discloses a wafer level packaging method. The wafer level packaging method includes that providing a substrate, wherein the substrate has a front surface and a back surface, and an interlevel dielectric layer and a welding pad located on the interlevel dielectric layer are formed in the front surface; forming a first through hole in the back of the substrate, wherein the interlevel dielectric layer exposes out of the first through hole; forming a polymer layer at each of the back surface of the substrate and the side wall of the first through hole; etching the interlevel dielectric layer, and etching to remove the polymer layers when etching the interlevel dielectric layer; repeating the steps of forming the polymer layer at each of the back surface of the substrate and the side wall of the first through hole, etching the interlevel dielectric layer, and etching to remove the polymer layers when etching the interlevel dielectric layer till exposing the welding pad, and forming a second through hole. According to the technical scheme, when etching the interlevel dielectric layer, the polymer layers protect the back of the substrate and the side wall of the first through hole from damage, the surfaces of the back of the substrate and the side wall of the first through hole are smooth, the electrical signals of wires in the second through hole are good, and the performance of the packaging structure is good.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Preparation method and application of sensor based on screen-printed carbon electrode

ActiveCN104931554AFlexible designLow costMaterial electrochemical variablesCarbamate pesticidesPre treatment

The invention discloses a preparation method and an application of a sensor based on a screen-printed carbon electrode and belongs to the technical field of biological sensors. The method comprises steps as follows: a dicyclohexyl phthalate / multiwalled carbon nanotube nano material is prepared and dripped on the surface of the screen-printed carbon electrode layer by layer, then acetylcholine esterase is dripped on the screen-printed work electrode surface modified with a dicyclohexyl phthalate / multiwalled carbon nanotube, and the acetylcholine esterase biological sensor for detecting organophosphorus and carbamate pesticides is prepared. The prepared sensor has the characteristics of simple work procedure, convenience in operation, low cost, high detection sensitivity, strong electric signal and simplicity in electrode pre-treatment and is applied to detection of pesticide residues, and the detection limit reaches 0.05 mu g / L.

Owner:SHANDONG EMBER INSTR

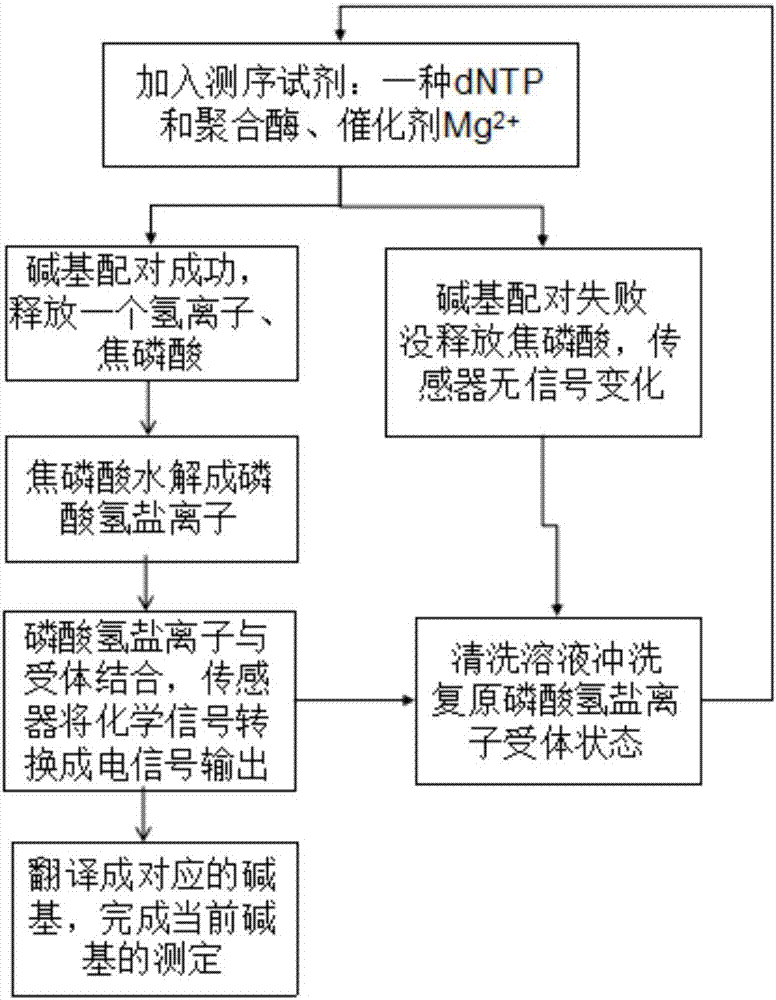

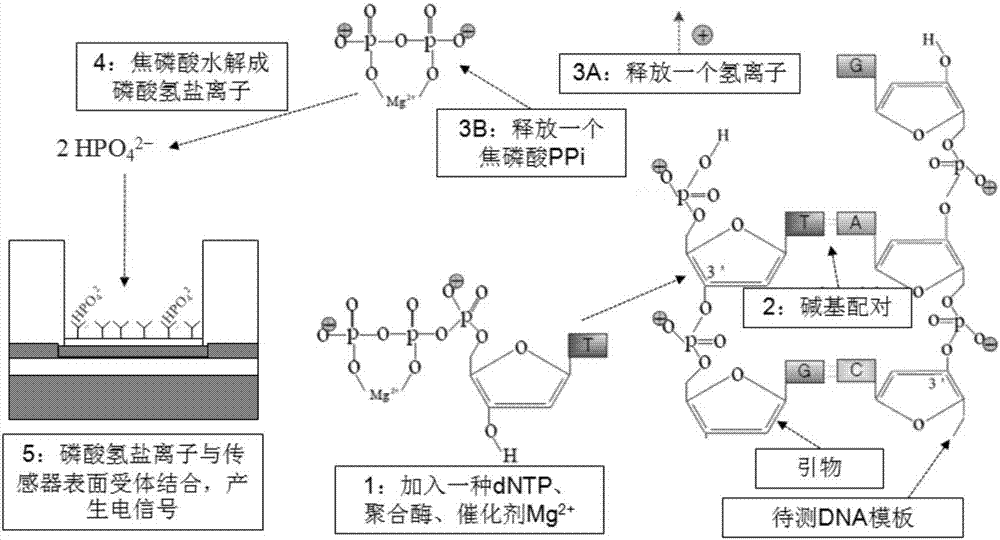

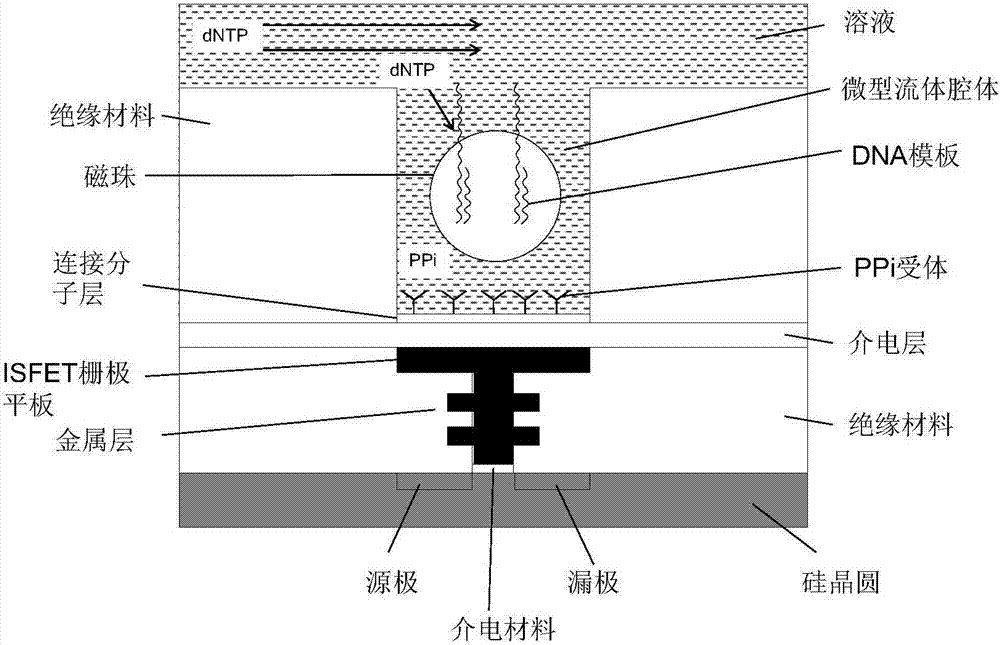

Gene sequencing method realized by detecting pyrophosphoric acid charges

InactiveCN107460233ALong electrical signalImprove accuracyMicrobiological testing/measurementSensor arrayEffective surface

The invention discloses a gene sequencing method capable of increasing the signal-to-noise ratio by detecting pyrophosphoric acid charges. According to the method, by adding dNTP, polymerases and catalysts to a reaction system, pyrophosphoric acid is released through base pairing, pyrophosphoric acid is hydrolyzed to generate hydrogen phosphate ions, and the hydrogen phosphate ions are combined with sensor surface receptors to generate electrical signals which are further translated into corresponding bases. Pyrophosphoric acid generated during amplification can be detected, the diffusion rate of pyrophosphoric acid is much slower than that of hydrogen ions because the relative molecular mass of pyrophosphoric acid is 174, electrical signals which can be detected last for a long time, and accuracy can be effectively improved. Besides, pyrophosphoric acid has four positive charges, diffusion is slowed down, effective surface concentration is high, the converted electric signals are strong, and the detected signal-to-noise ratio is high. The high signal-to-noise ratio allows the use of smaller sensors and a sensor array with higher density and larger scale, so that sequencing throughput can be further improved and sequencing cost can be reduced.

Owner:ZHANGJIAGANG ONECHIP BIO TECH CO LTD

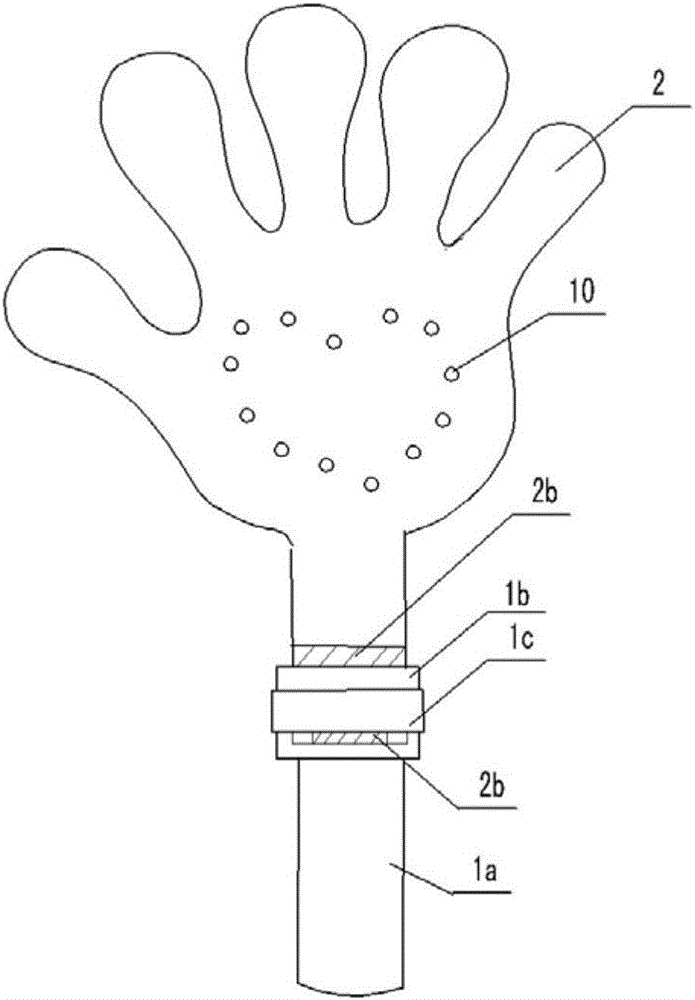

Self-driven luminescence applauding device based on friction nanometer motors and preparation method of applauding device

PendingCN106730882ARealize self-driven lighting effectReduce dependenceMusical toysFriction generatorsNanogeneratorMechanical energy

The invention discloses a self-driven luminescence applauding device based on friction nanometer motors and a preparation method of the applauding device. The applauding device comprises two palms and at least one friction nanometer motor, and each friction nanometer motor is formed by two friction parts which are fixed on the beating surfaces of the palms respectively; the first friction part is a flexible substrate where a metal aluminum sheet and a PDMS film are fixed sequentially, and array type PDMS bulges are integrally formed on the surface of the PDMS film; the second friction part is a flexible substrate where a metal aluminum sheet is fixed, and array type aluminum bulges are arranged on the metal aluminum sheet; electrodes are led out from the metal aluminum sheets of the two friction parts and connected with the pins of light emitting diodes respectively; mechanical energy is formed when the two palms are clapped, and the friction nanometer motors convert the mechanical energy into electric energy so that the light emitting diodes can illuminate. The self-driven luminescence applauding device is simple in structure and stable in performance and has a wide application prospect.

Owner:HEFEI UNIV OF TECH

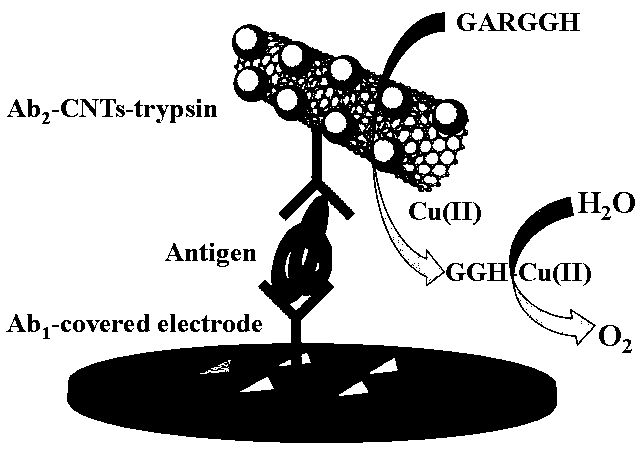

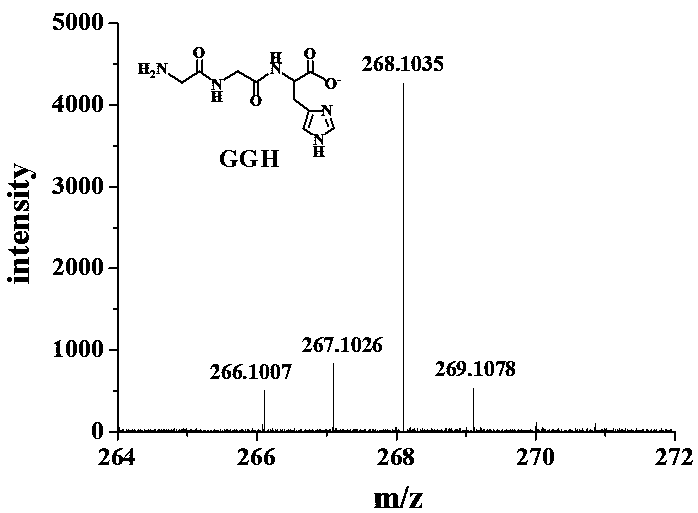

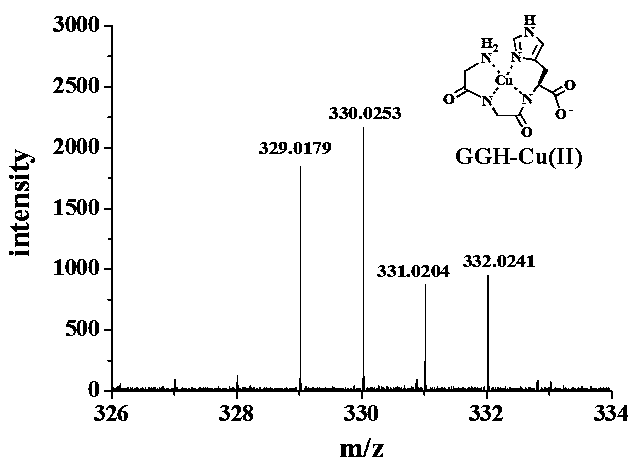

Electrochemical immunosensor electric signal marker for prostate specific antigen detection and detection method

InactiveCN109470757AStrong electrical signalThe electrical signal is obvious, and the stability is obviousDisease diagnosisBiological testingAntigenCarbon nanotube

The invention discloses an electrochemical immunosensor electric signal marker for prostate specific antigen detection. The electric signal marker is protease, and a catalytic substrate of the protease is polypeptide with the sequence characteristic that the third amino acid from a cleavage site to a carbon end is histidine H. A detection method for prostate specific antigen detection adopts the electrochemical immunosensor electric signal marker for prostate specific antigen detection. The method comprises the steps as follows: A, preparing a secondary antibody / carbon nanotube / protease compound; B, preparing a working electrode; C, soaking the working electrode in a PBS solution containing copper ions and the polypeptide substrate for 2 h, and conducting an electrochemical test with linear sweep voltammetry. The electrical signal marker has obvious electrical signals, can meet the requirement of detection of concentration of prostate specific antigens in human serum and is harmless toworkers and environments due to the fact that no biphenyl substances are used in the catalytic substrate.

Owner:ANYANG NORMAL UNIV

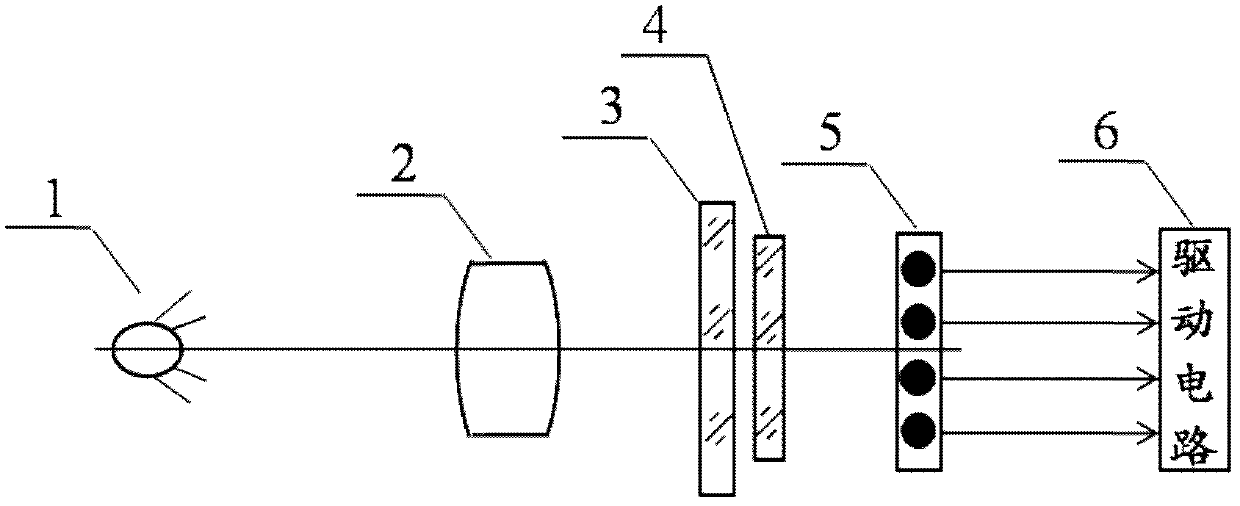

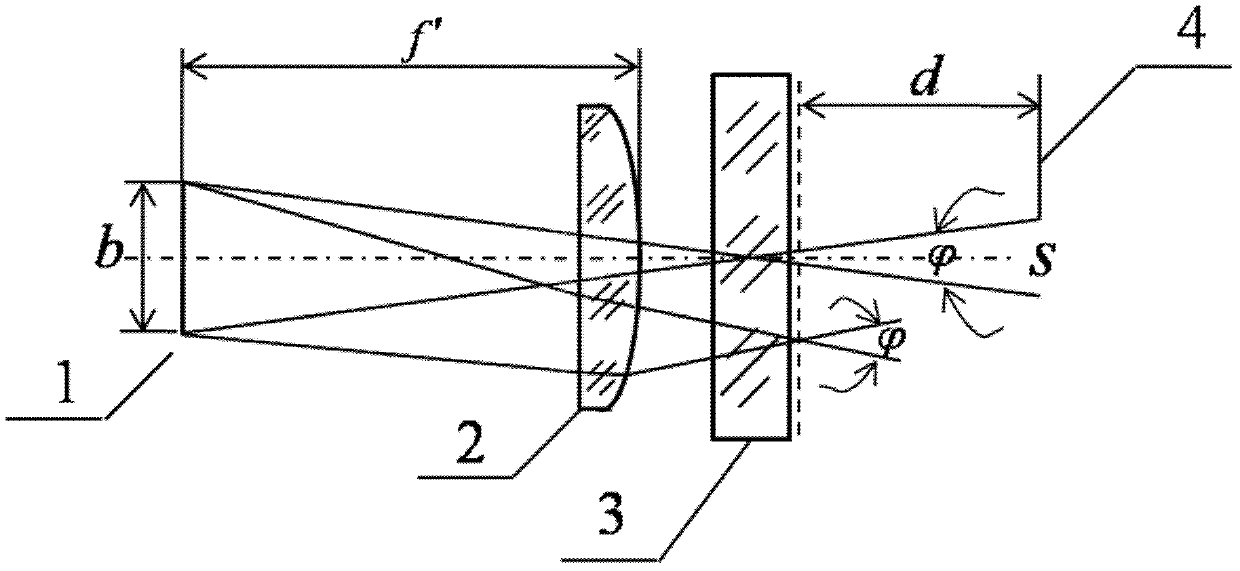

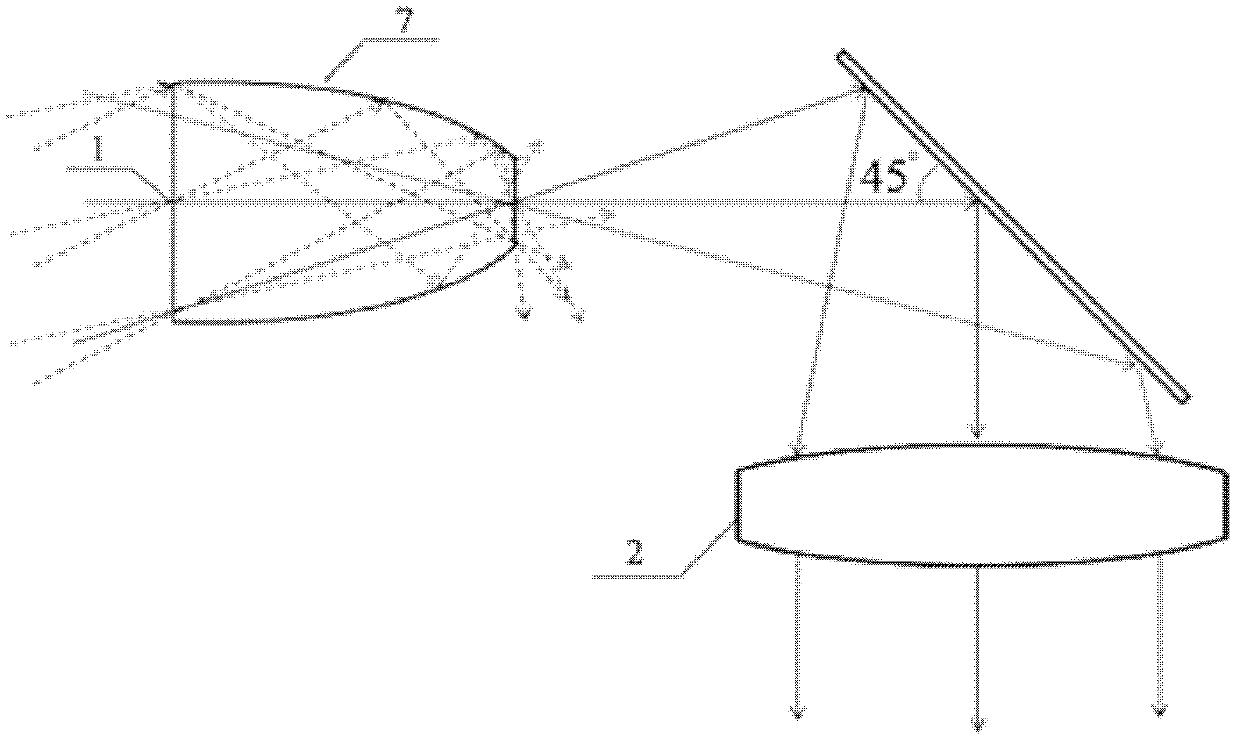

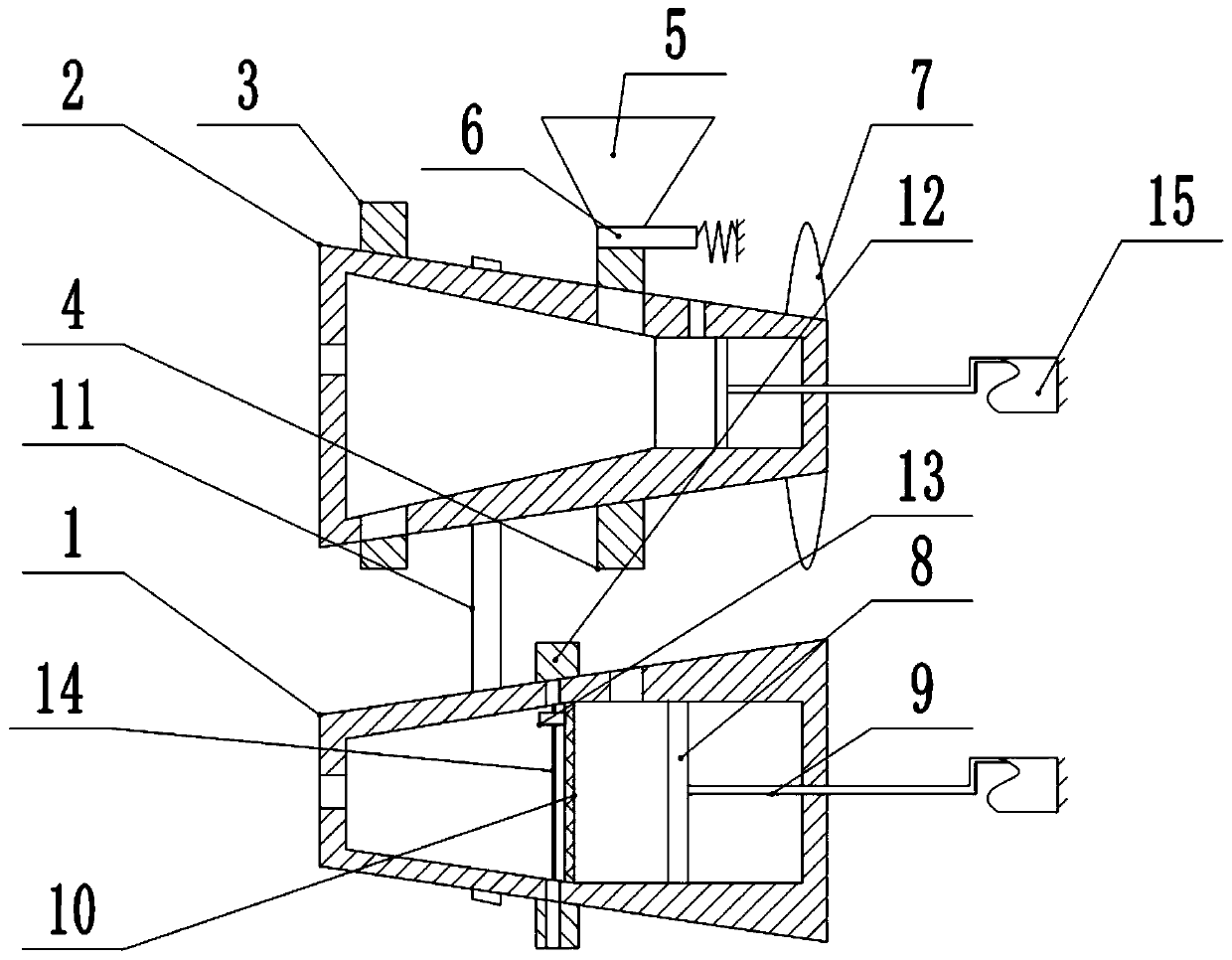

Design method for condensing element for improving illumination system of grating reading head

InactiveCN102607415AIncrease luminous fluxGood collimationUsing optical meansCondensersGratingOptical axis

A design method for a condensing element for improving an illumination system of a grating reading head belongs to the technical field of optics. According to the method, the size of light source is reduced, electric signals can be stably output, and the resolution and precision of a grating measuring device can be increased. The method includes the following steps: the position of the condensing element is first determined, i.e., the condensing element is between the light and a collimating lens, and is on the same optical axis as the illumination system of the grating reading head; according to the specific structure of the grating reading head and the mounting position of the condensing element, the size of the light passing through the condensing element is determined; and according to the actual size of the light source, the size of the light passing through the condensing element and the maximum incidence half-angle of the light capable of being received by the condensing element, the axial length and focal length of the condensing element are determined. The luminous flux of the light is increased, and the electric signals outputted by the illumination system of the grating reading head are strong; the collimation and parallelism of the emergent light passing through the condensing element are high; when the illumination system is used for measuring a grating scale, the measurement precision is high, and response speed is high.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

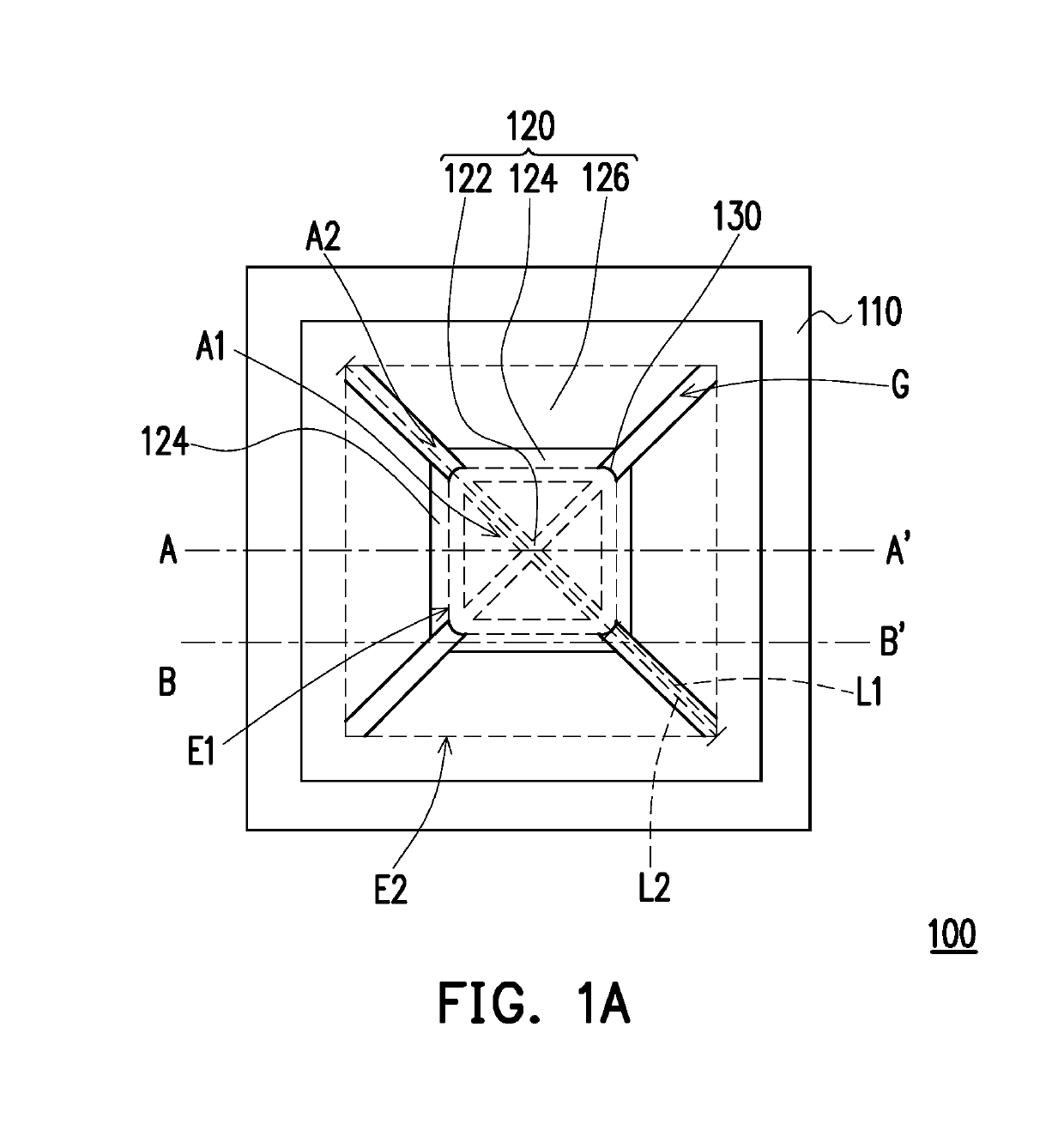

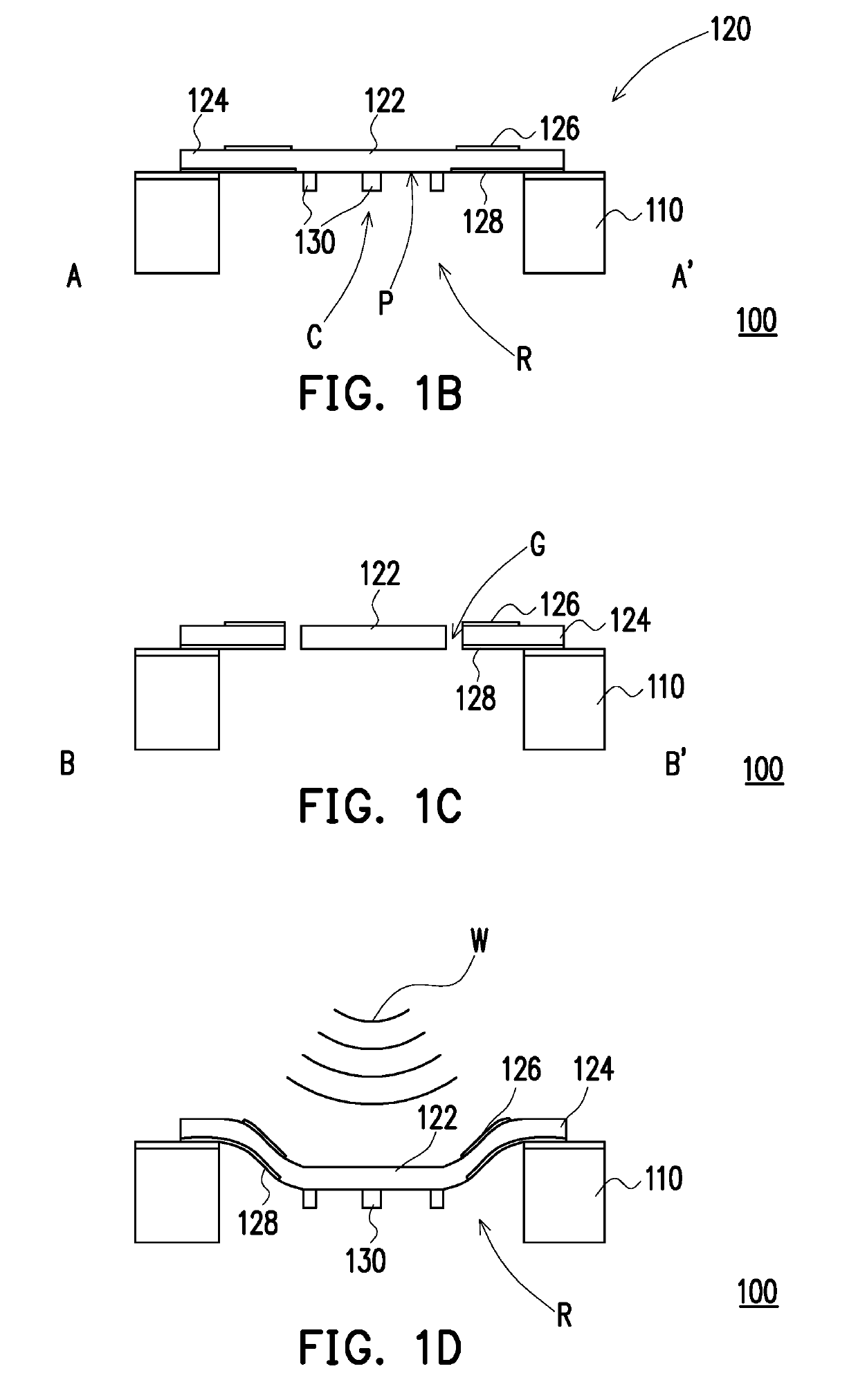

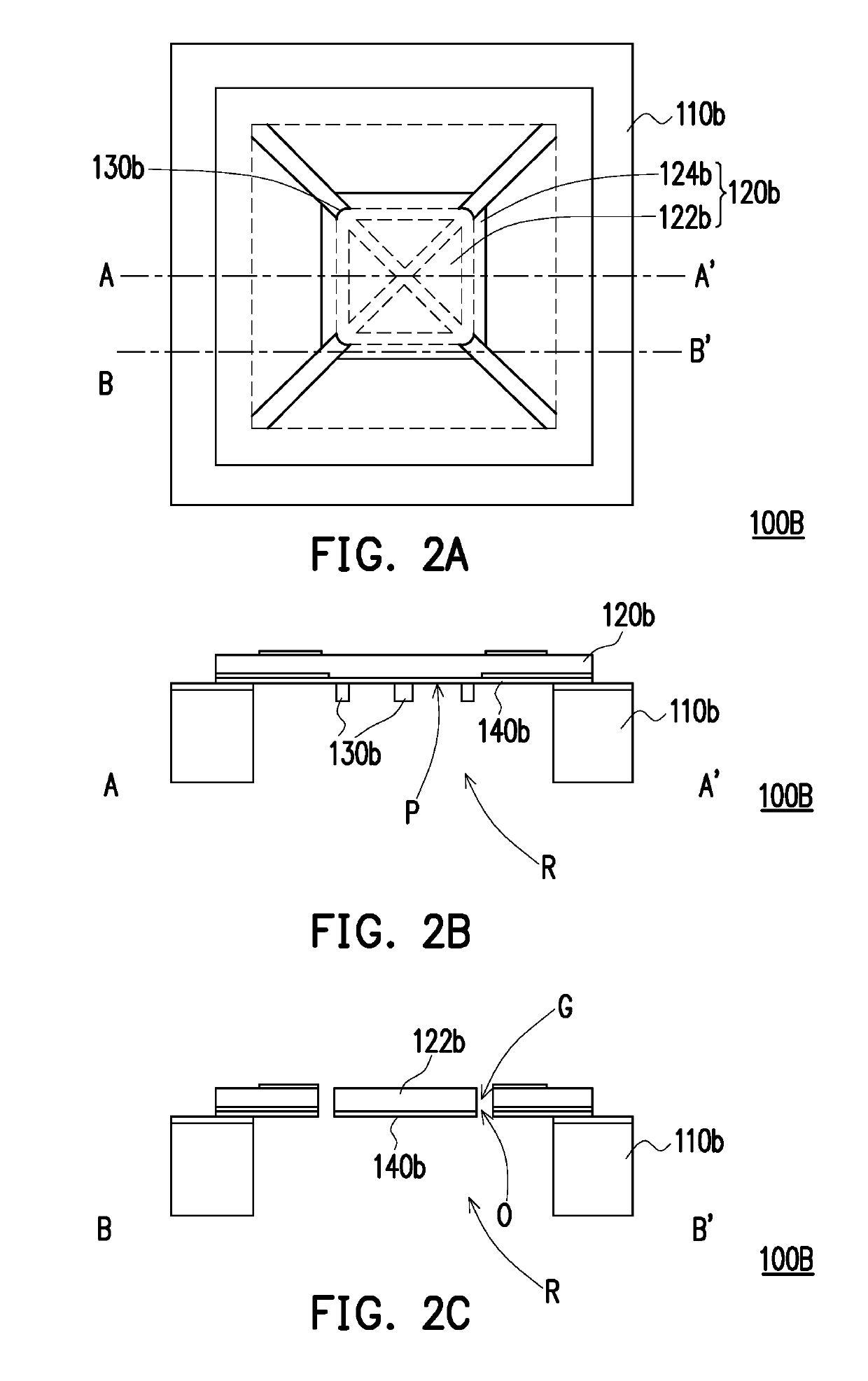

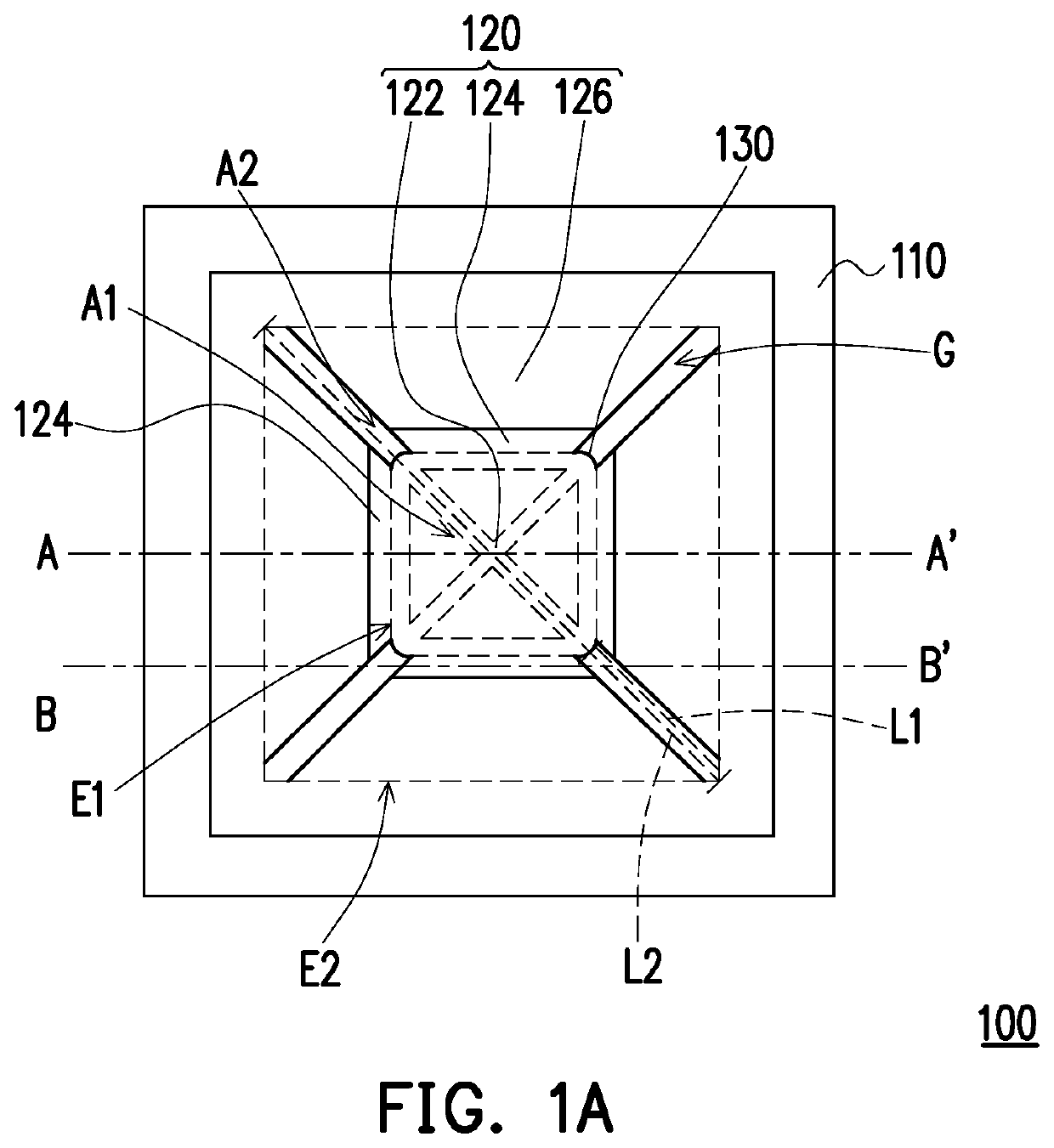

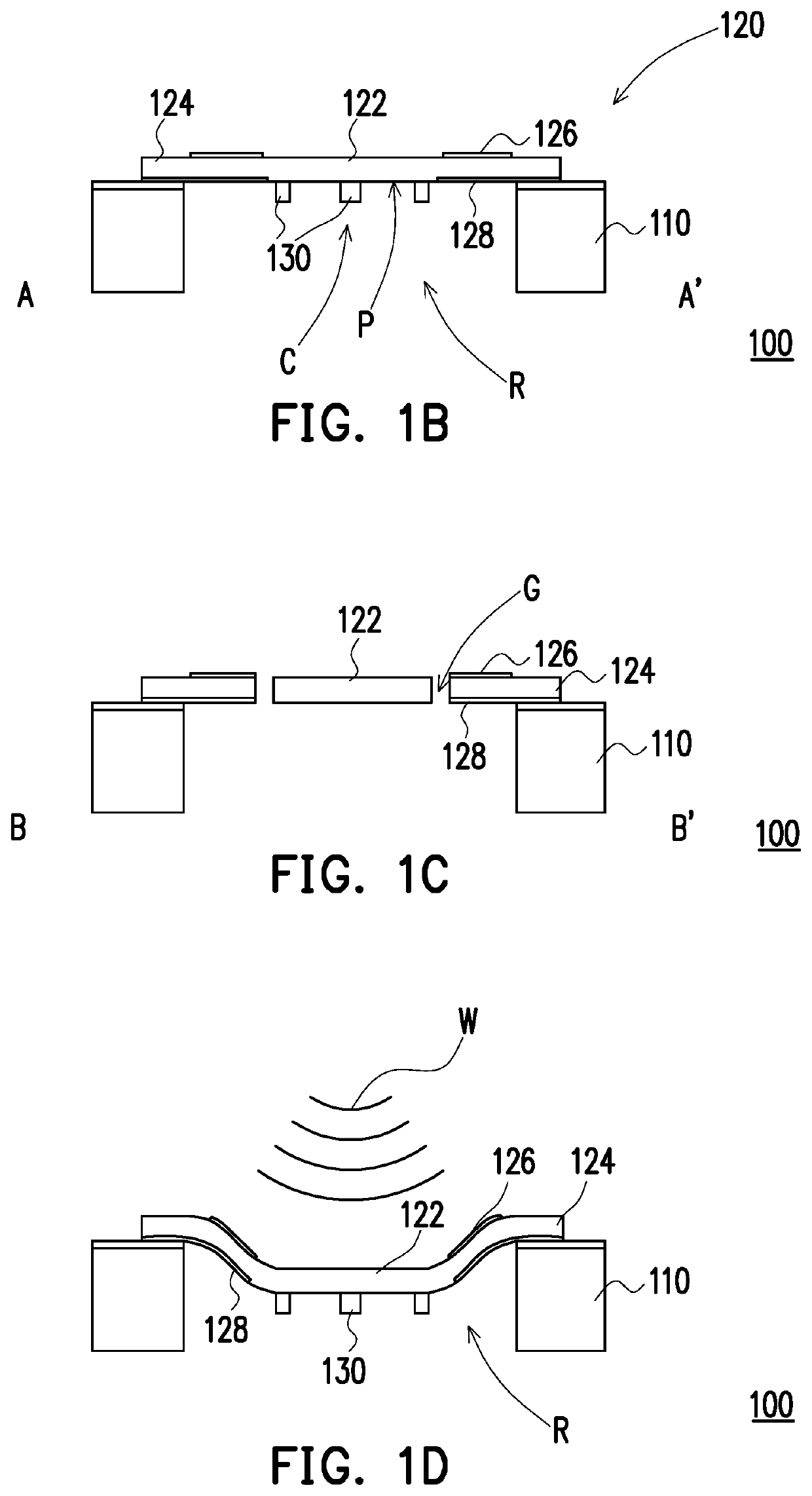

Piezoelectric transducer

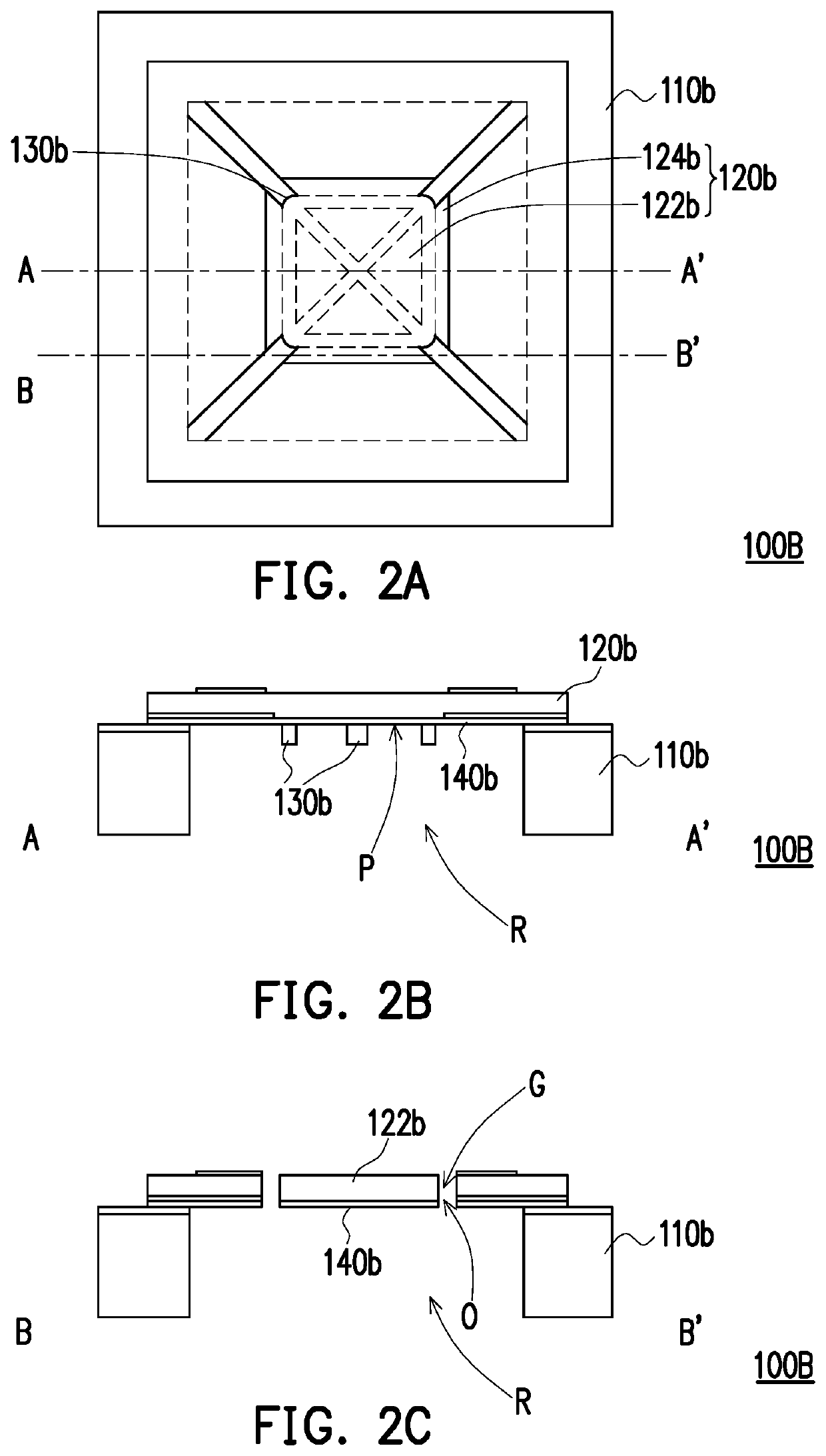

ActiveUS20190222940A1Improve sensor sensitivityPressure balancePiezoelectric/electrostrictive microphonesMicrophonesTransducerPiezoelectric transduction

A piezoelectric transducer including a substrate, a piezoelectric layer and a stiffening structure is provided. The substrate has a chamber. The piezoelectric layer has a displacement zone, a plurality of sensing zones, a plurality of gaps, a plurality of top electrodes, and a plurality of bottom electrodes. The displacement zone is located over the chamber. The sensing zones are surroundingly connected to an outer edge of the displacement zone and are located over the chamber. The gaps are each formed between any adjacent two of the plurality of sensing zones, and each of the gaps communicates with the chamber. The top electrodes are each disposed on a top surface of each of the sensing zones. The bottom electrodes are each disposed on a bottom surface of each of the sensing zones. The stiffening structure is disposed on a bottom of the displacement zone.

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

Piezoelectric transducer

ActiveUS10536780B2Improve sensor sensitivityPressure balancePiezoelectric/electrostrictive microphonesMicrophonesEngineeringMechanical engineering

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

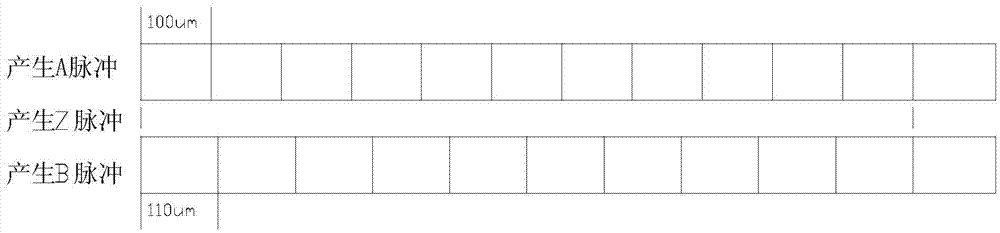

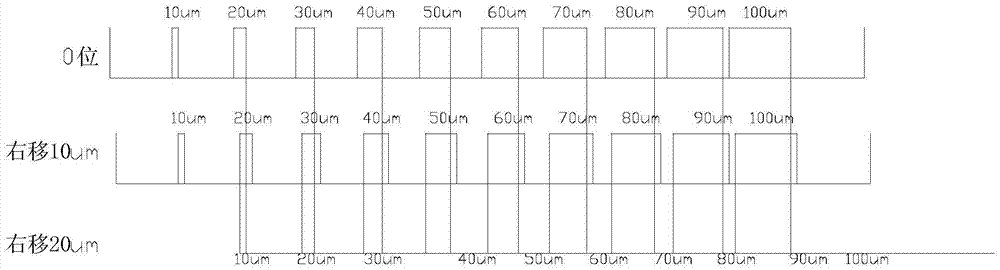

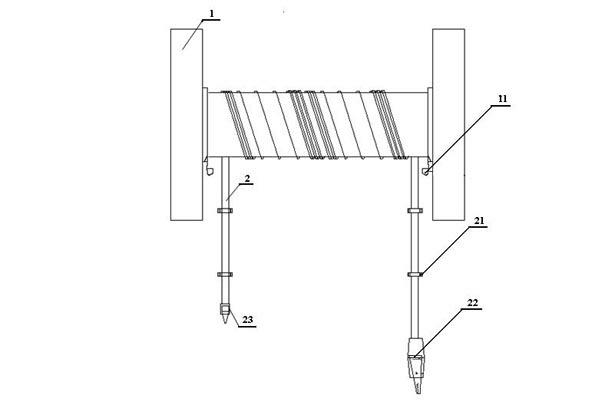

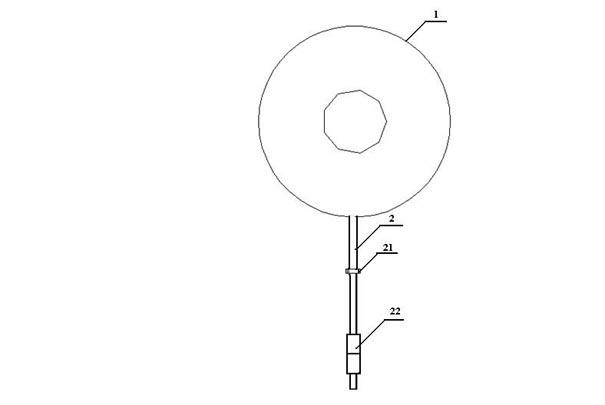

Linear grating scale of numerical control machine tool

InactiveCN105436995AGood pollution effectImprove anti-interference abilityMeasurement/indication equipmentsNumerical controlPhase grating

The invention relates to a linear grating scale of a numerical control machine tool. The linear grating scale of the numerical control machine tool comprises a number reading head and a grating scale body. The linear grating scale of the numerical control machine tool is characterized in that the grating scale body is provided with two rows of grating lines, namely, a first row of grating lines and a second row of grating lines; the first row of grating lines is scaled at equal distance, so is the second row of grating lines; the scaling distance of the first grating lines is greater than that of the first row of grating lines; pulse is between the first row of grating lines and the second row of grating lines. According to the linear grating scale of the numerical control machine tool, the method that two rows of A-B-phase grating lines are scaled at every 100 microns and are staggered in 10 microns is adopted, and the effective working grating torque is 10 microns, so that the manufacturing difficulty can be greatly reduced, and the oil-water pollution resistance can be effectively improved; the anti-interference performance of pulse signals generated by a photoelectric cell unit is high. The linear grating scale is high in novelty and creativity and high in practical value.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Dust detection and purification device

ActiveCN108956396BLarge refraction angleBig change in strengthDispersed particle filtrationTransportation and packagingFiberDust detection

The invention belongs to the field of detection equipment, and specifically discloses a dust detection and purification device, which includes a frame on which a driving roller and a driven roller are rotatably connected. It is set opposite to the driven roller; the driven roller is covered with a first bump and a second bump, and a belt for transmission is also provided between the driving roller and the driven roller, and the belt is located between the first bump and the second bump. There is a magnetic block between the bumps and on the belt; fiber filter cloth is provided in the cavity of the driving roller on the side of the piston away from the piston rod, and a filter cloth is provided on the driven roller to match the feed port and communicate with the cavity. A through hole, the driven roller is also provided with a through hole that matches the discharge port and communicates with the cavity; the cavity of the driving roller is provided with a detection unit on the side close to the small diameter end of the driving roller. By adopting the solution of the present invention, the requirement that the dust can be purified in time after the dust detection is completed is met.

Owner:重庆博创知识产权运营有限公司

Wafer Level Packaging Method

ActiveCN104617033BStrong electrical signalImprove performanceSemiconductor/solid-state device manufacturingEngineeringDielectric layer

The invention discloses a wafer level packaging method. The wafer level packaging method includes that providing a substrate, wherein the substrate has a front surface and a back surface, and an interlevel dielectric layer and a welding pad located on the interlevel dielectric layer are formed in the front surface; forming a first through hole in the back of the substrate, wherein the interlevel dielectric layer exposes out of the first through hole; forming a polymer layer at each of the back surface of the substrate and the side wall of the first through hole; etching the interlevel dielectric layer, and etching to remove the polymer layers when etching the interlevel dielectric layer; repeating the steps of forming the polymer layer at each of the back surface of the substrate and the side wall of the first through hole, etching the interlevel dielectric layer, and etching to remove the polymer layers when etching the interlevel dielectric layer till exposing the welding pad, and forming a second through hole. According to the technical scheme, when etching the interlevel dielectric layer, the polymer layers protect the back of the substrate and the side wall of the first through hole from damage, the surfaces of the back of the substrate and the side wall of the first through hole are smooth, the electrical signals of wires in the second through hole are good, and the performance of the packaging structure is good.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A novel method of transferring graphene film and the preparation method of sensor

InactiveCN106946248BTransfer losslessReduce the difficulty of operationCarbon compoundsConverting sensor output electrically/magneticallyParaffin waxComposite film

The invention provides a novel graphene thin film transferring method and a preparation method of a sensor and relates to the technical field of graphene. The novel graphene thin film transferring method comprises the following steps: covering melted paraffin wax on the surface of a graphene thin film which is formed on the surface of a growth substrate; after the paraffin wax is cured, removing the growth substrate to obtain a paraffin wax / graphene composite thin film; putting the paraffin wax / graphene composite thin film on the surface of a target substrate; heating the target substrate until the paraffin wax is fitted to the target substrate and removing the paraffin wax by utilizing a solvent. The method provided by the invention takes the paraffin wax as a novel transferring medium and is convenient to operate; and the graphene thin film can be basically transferred in a lossless manner. The preparation method of the sensor comprises the following steps: a channel electrode is manufactured on the surface of the graphene thin film prepared using the transferring method and a pattern of a touch sensor is formed by the graphene thin film; and an optical adhesive is fitted on the surface of the graphene thin film and then de-foaming treatment is carried out. By adopting the method provided by the invention, the obtained graphene thin film is complete, basically has no loss and has large area, and can be used for manufacturing the sensor.

Owner:成都川烯科技有限公司

Magnetostrictive biosensor driving device

PendingCN109100414ALow modification costLow input costMaterial magnetic variablesElectricityPower flow

The invention provides a magnetostrictive biosensor driving device. A DC solenoid coil is wound on an iron core, the upper end of the iron core is fixed on a coil mounting seat, an AC flat coil is fixed on the coil mounting seat, the AC flat coil is is arranged in parallel with a magnetostrictive biosensor, the magnetostrictive biosensor is fixed on a sensor mounting seat, the coil mounting seat is fixed on a first shell, and the sensor mounting seat is fixed on a second shell. According to the magnetostrictive biosensor driving device provided by the invention, a driving magnetic field is changed by adjusting the current, a driving coil can be separately modified according to different AC and DC magnetic field requirements, thereby reducing the repeated modifications and the input cost ofthe hardware circuit drive; and by reducing the use of permanent magnets, precise control of the magnetic field can be achieved to achieve optimal electrical signals.

Owner:深圳砺剑脑科学科技有限公司

A high-sensitivity piezoelectric microphone and its manufacturing method

ActiveCN109511023BIncrease vibration displacementIncreased strain stressMouthpiece/microphone attachmentsThin membraneEngineering

The invention discloses a piezoelectric microphone with high sensitivity as well as a production method. The piezoelectric microphone comprises a base provided with a cavity and a piezoelectric stacking structure arranged on the base, the cavity in the base is a vacuum vibration cavity, the piezoelectric stacking structure sequentially comprises a bottom electrode, a piezoelectric film and a top electrode, and the base comprises a base bottom layer, a base intermediate layer and a base top layer. The production method comprises the following steps: firstly etching the cavity in the base bottomlayer, then depositing the base intermediate layer, then bonding the base top layer on the base intermediate layer in a vacuum environment, so as to form a vibration cavity, then etching an annular groove on the base top layer, depositing a sacrificial layer in the annular groove, then sequentially depositing the bottom electrode, the piezoelectric film and the top electrode on the base top layer, forming a corrosion hole in the top electrode, and corroding off the sacrificial layer, so that production of the piezoelectric microphone is completed. The piezoelectric microphone disclosed by theinvention can guarantee a vacuum state inside the cavity, air resistance does not exist, strain stress of the piezoelectric film is greatly improved, and a stronger electrical signal is output.

Owner:武汉敏声新技术有限公司

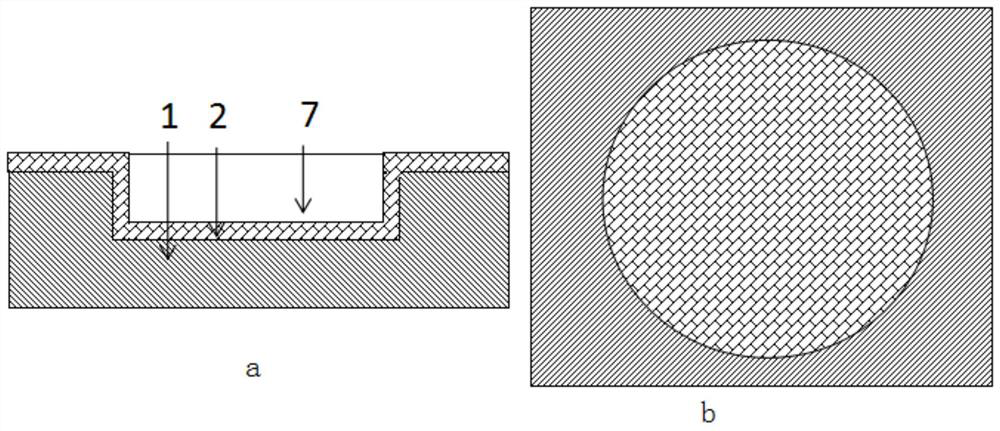

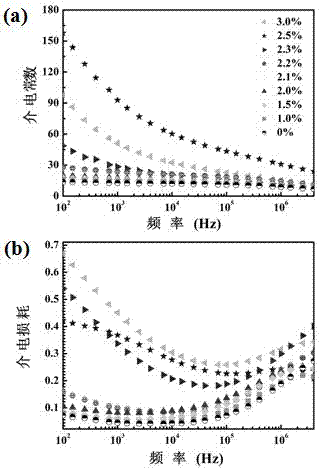

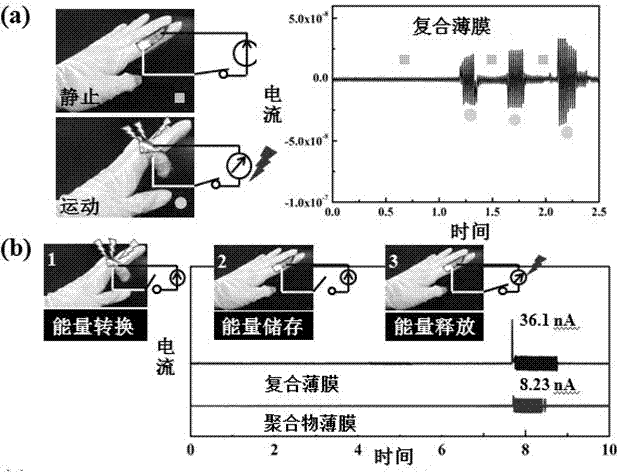

Preparation method of modified graphene oxide-piezoelectric polymer energy storage thin film device

The invention discloses a preparing method for a modified graphene oxide-piezoelectric polymer energy-storing thin-film device. According to the preparing method, at first, a thin-film material is prepared, perfluoro nitrine benzoic acid and graphene oxide are subjected to a covalent reaction through heating so that micro-molecular modifying agents can be connected to the surface of modified graphene oxide, then the modified graphene oxide is washed cleanly through ethyl alcohol, frozen, dried, and then dispersed in N, N-dimethylformamide in an ultrasonic mode, a certain quantity of polyvinylidene fluoride-hexafluoropropylene copolymers is added, the mixture is heated and stirred, a tape-casting method is used for preparing a composite thin film, after heating is carried out to remove solvent, the thin film is cooled and recrystallized, then the thin film and a substrate are soaked in water, and the thin film is taken down; finally, the prepared thin film is prepared into the device, two pieces of copper foil are connected to the upper face and the lower face of the thin film respectively to serve as current collectors, wires are led out of the copper foil, or the copper foil can be directly connected with a test instrument for testing, and namely the flexible thin-film device integrating an electricity generation ability and an electricity storage ability is prepared.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

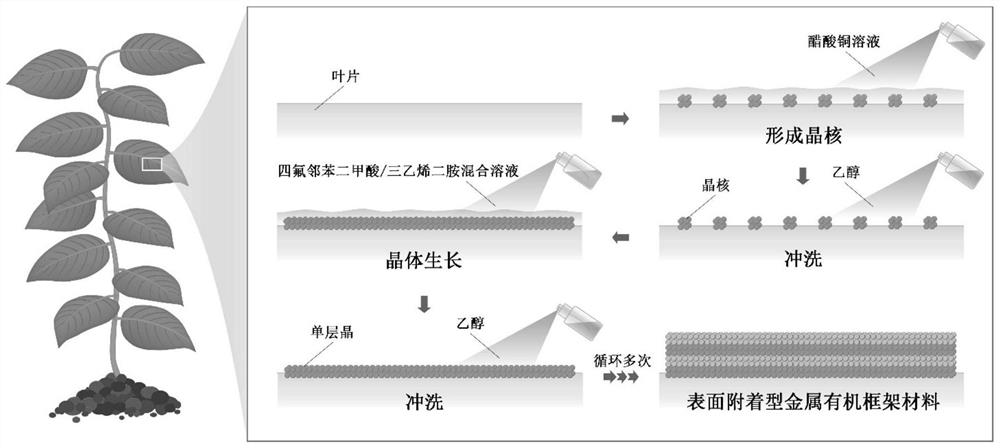

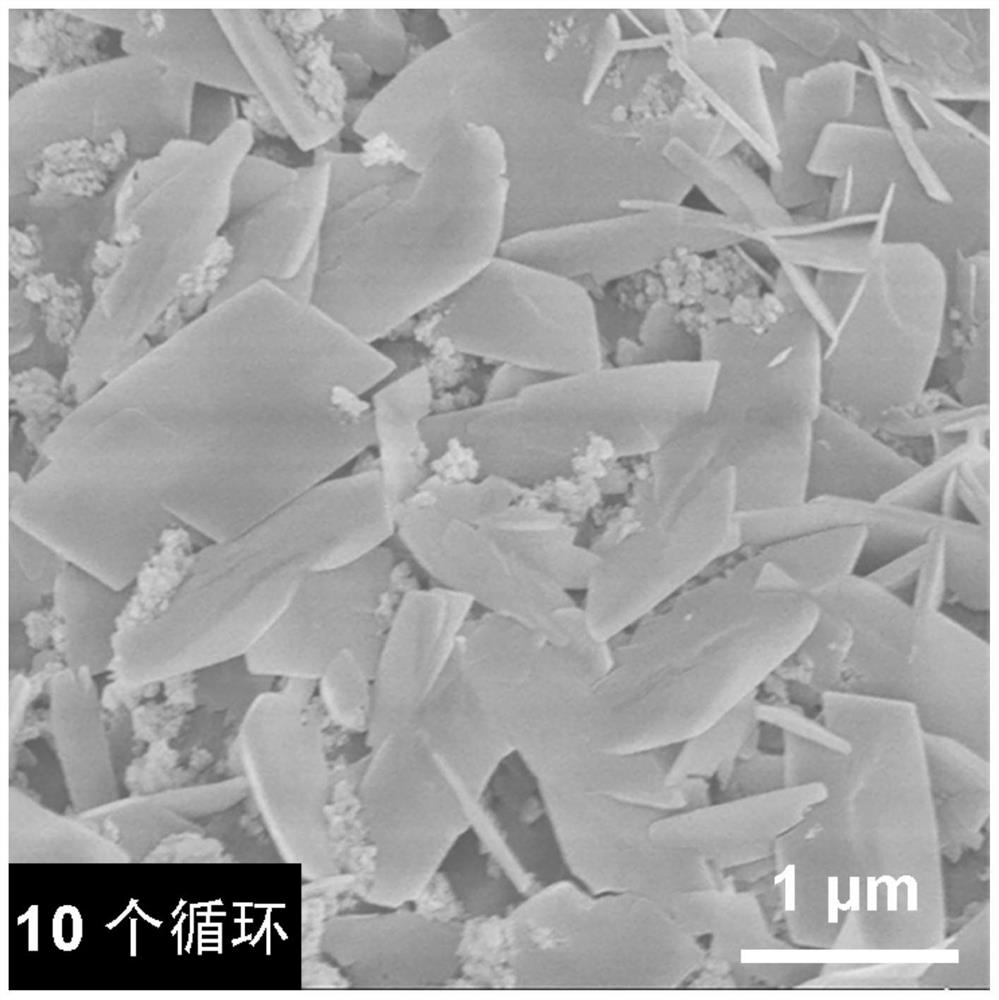

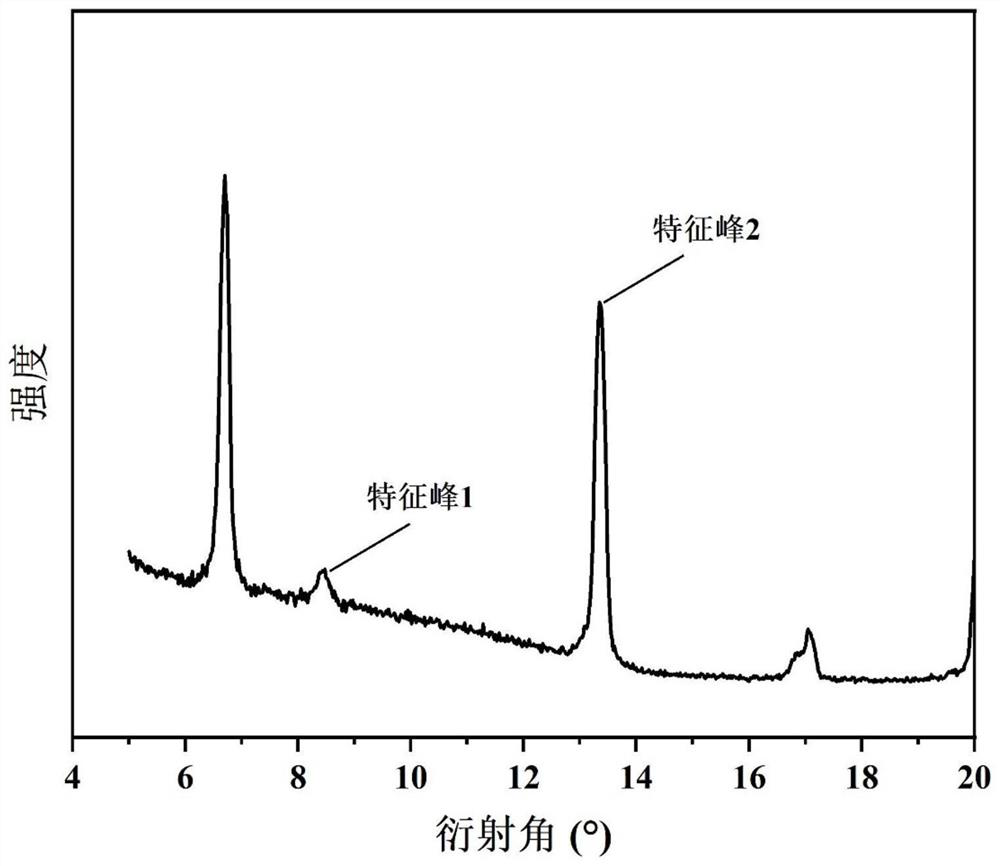

Preparation method and application of MOF-based plant leaf friction nano-generator

ActiveCN113193779APromote commercial applicationImprove capture abilityCoatingsFriction generatorsNanogeneratorAlcohol

The invention discloses a preparation method and application of an MOF-based plant leaf friction nano-generator. The preparation method comprises the following steps: washing a substrate clean, preparing a copper acetate solution, and mixing a tetrafluorophthalic acid solution and a triethylene diamine solution to obtain a mixed solution A; spraying a copper acetate solution, the mixed solution A and absolute ethyl alcohol on the surface of a substrate, wherein the copper acetate solution, the absolute ethyl alcohol, the mixed solution A and the absolute ethyl alcohol are sequentially sprayed; after each solution is sprayed, using a fan with a heating function for evaporating absolute ethyl alcohol on the surface of the substrate; and repeatedly spraying for a plurality of times to obtain the MOF-based plant leaf friction nano-generator. The nano-generator has the advantages of being easy to prepare, good in biocompatibility, high in sensitivity and free of batteries, can stably work for a long time, and is an excellent substitute of a traditional wind speed sensor.

Owner:ZHEJIANG UNIV

A kind of sensor preparation method and application based on screen printing carbon electrode

ActiveCN104931554BAvoid disadvantagesIncreased current responseMaterial electrochemical variablesPesticide residueCarbon nanotube

Owner:SHANDONG EMBER INSTR

Wide-dynamic range image sensor and control method thereof

ActiveCN102547159BImprove dynamic rangeStrong electrical signalTelevision system detailsColor television detailsFloating diffusionComputer science

The invention relates to the field of image sensors, and discloses a wide-dynamic range image sensor and a control method thereof. According to the invention, a plurality of photoreceptors and a plurality of transfer transistors are arranged in each pixel; in each integration period, the photoreceptors are sequentially connected with a floating diffusion area according to a preset time sequence respectively, the photoreceptors are sequentially read, and the other photoreceptors are integrated in the reading process of a certain photoreceptor, so that concurrent integration can shorten total operation time and increase the operating speed of the image sensor in a wide-dynamic range operating mode; and a structure with two layers of micro lenses is adopted, so that each photoreceptor in the same pixel can sample optical signals of the same point, and the optical signal detection accuracy of the image sensor is improved.

Owner:重庆子丘软件有限公司

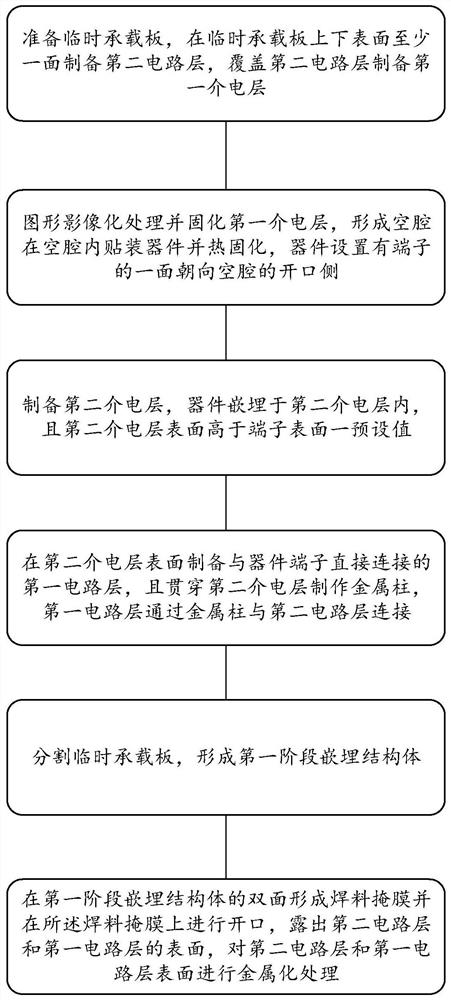

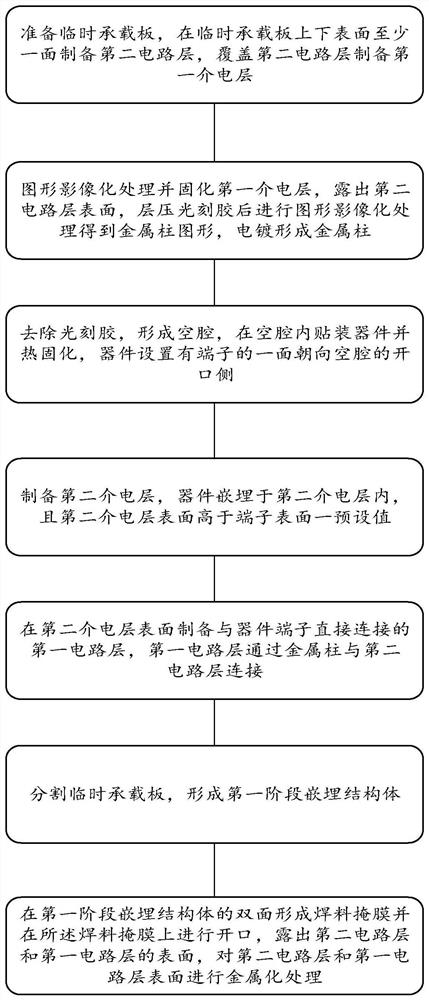

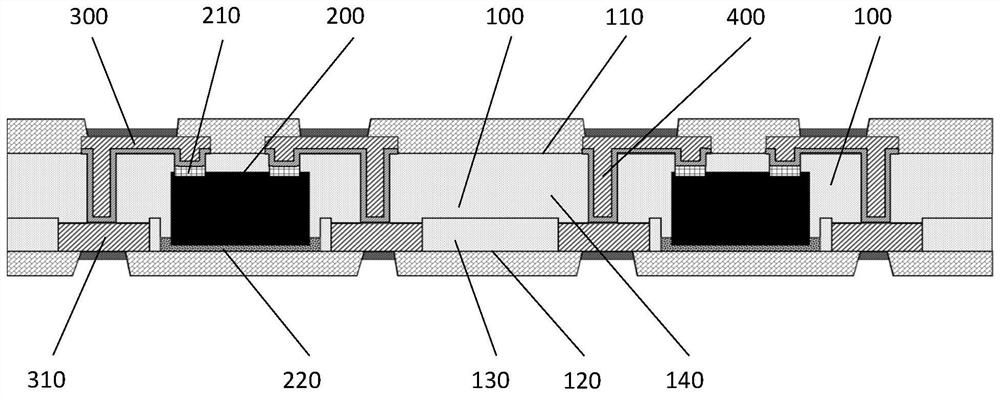

Embedded structure, preparation method, and substrate

ActiveCN112103193BReduce the hidden danger of poor fillingReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsMechanical engineering

The invention discloses a method for preparing an embedded structure, which comprises the steps of: making a second circuit layer on a temporary bearing plate, covering the second circuit layer to make a first dielectric layer, image-processing the first dielectric layer to form a paste The cavity of the device is installed, so that the side of the device with the terminal is facing the opening of the cavity, and the second dielectric layer is prepared, so that the device is embedded in the second dielectric layer, and the surface of the device terminal and the surface of the second dielectric layer are A preset value, the first circuit layer is prepared on the surface of the second dielectric layer, and the first circuit layer is directly connected to the terminal of the device. The invention also discloses an embedded structure and a substrate containing the embedded structure. Through the implementation of the present invention, the process steps of the embedded structure in the prior art are simplified. The device and the circuit are connected by electroplating to ensure the stability of the connection between the device and the circuit and ensure a good electrical signal.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

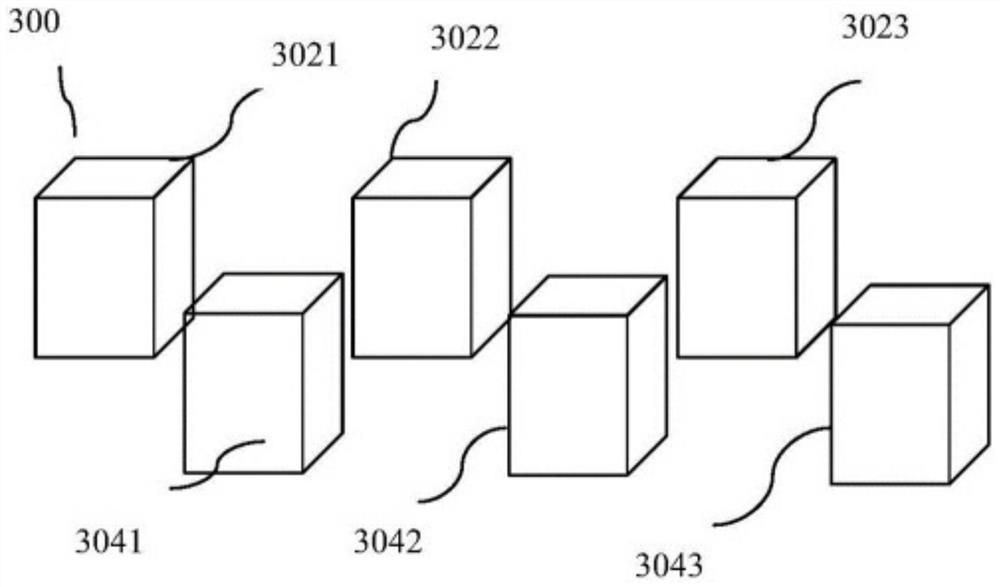

Heart rate recognition device

InactiveCN112741607AEffective filteringImprove signal-to-noise ratioSensorsMeasuring/recording heart/pulse rateEngineeringStructural engineering

The invention discloses a heart rate recognition device. The heart rate recognition device comprises an upper pressing plate, a lower base plate, a piezoelectric panel and a buffer layer; the upper pressing plate comprises an upper pressing plate panel and a first bulge group which is positioned on the lower side of the upper pressing plate panel and is provided with a plurality of vertically downward first bulges; the lower base plate comprises a lower base plate panel which is positioned below the upper pressing plate and is parallel to the upper pressing plate panel, and a second bulge group which is positioned on the upper side of the lower base plate panel and is provided with a plurality of vertically upward second bulges; the piezoelectric panel is clamped between the first bulge group and the second bulge group; and the buffer layer is located among the upper pressing plate, the lower base plate, and the piezoelectric panel. The heart rate recognition device has the beneficial effects that through a plurality of first contact faces and a plurality of second contact faces which are located on the upper side and the lower side of the piezoelectric panel and arranged in a staggered mode, the piezoelectric panel deforms multiple times, so that superposition of multiple electric signals is formed, the stronger electric signals can be output under the condition of bearing the same pressure, and heart rate recognition is more accurate.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Circumscribed earthing wire device with electrical noise interference resistance

InactiveCN102136639AWithout compromising data qualityImprove conductivityElectric connection basesMulticonductor cable end piecesInterference resistanceAlligator

The invention relates to a circumscribed earthing wire device with electrical noise interference resistance, which comprises a spool, a BV copper line, an insulation sleeve, and is characterized in that the spool is a laterally arranged I-shaped structural member the two ends of which are flat; the two ends of a shaft body in the middle of the spool are respectively provided with a stainless-steel ring-shaped hook with an upper opening in a sheathed mode; the length of the BV copper line is about 4-5m; a projection ring is arranged every other 0.5m; a plurality of perforations are arranged on the ring at equal interval; the BV copper line is sequentially wound on the shaft body in the middle part of the spool; and one end of the BV copper line is connected with a wiring nose while the other end is connected with an alligator clip.

Owner:SHANGHAI OCEAN UNIV

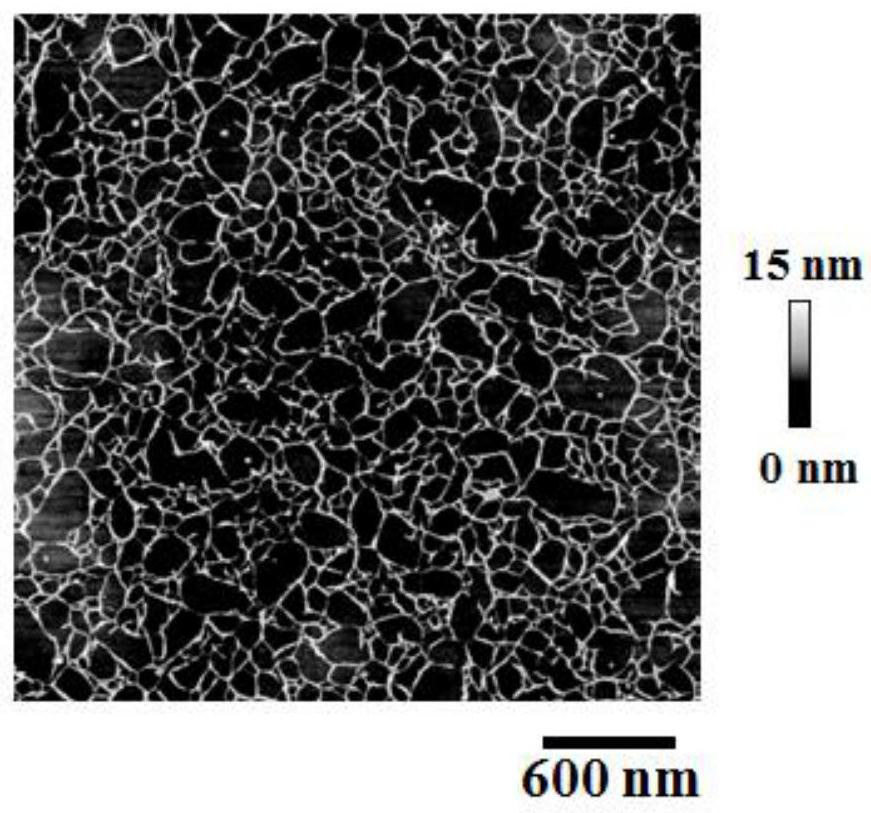

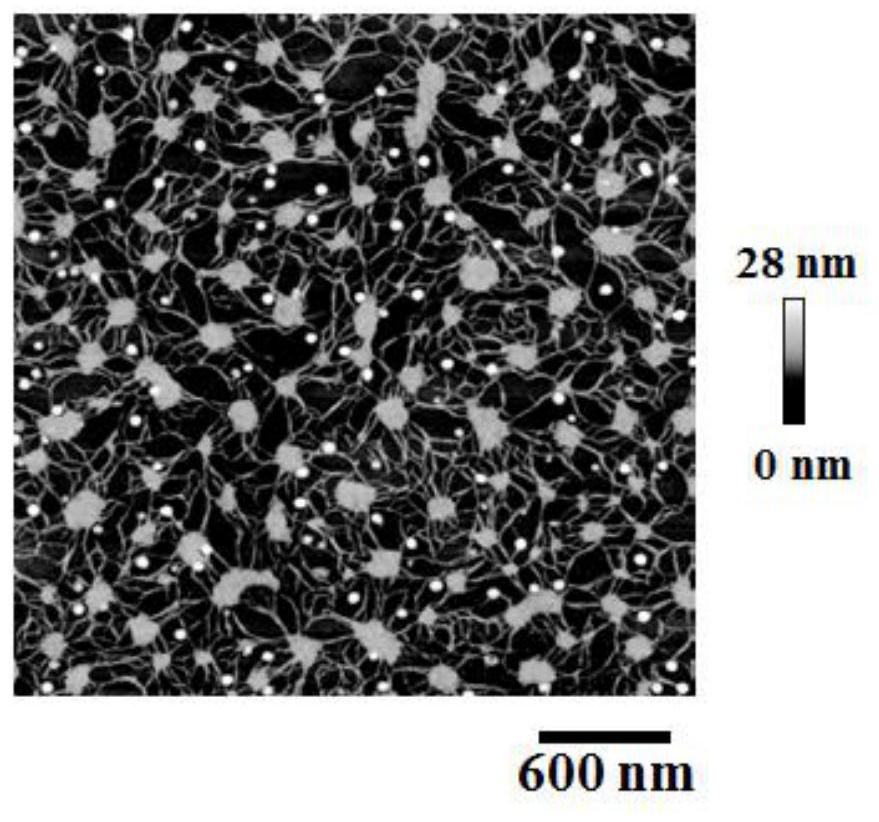

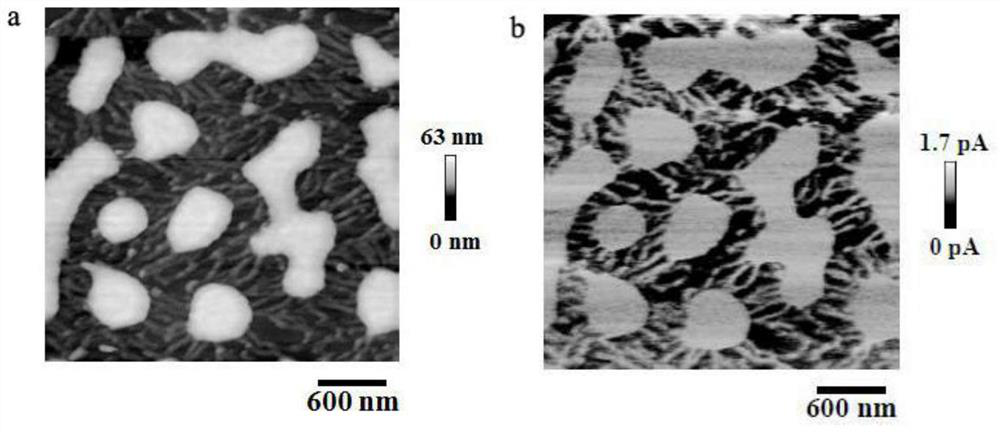

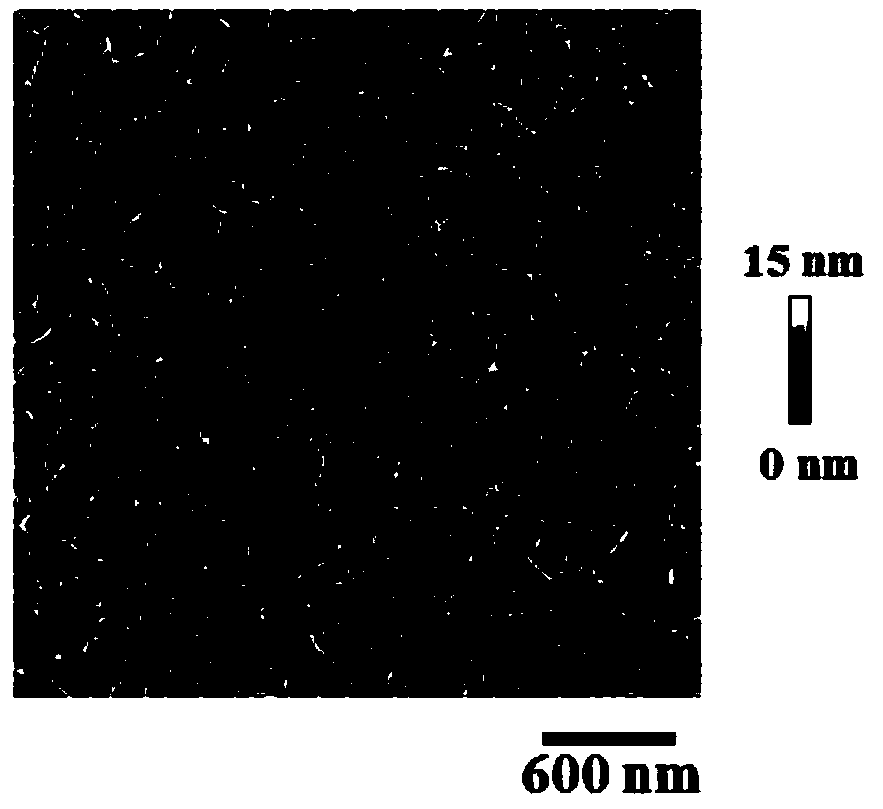

A method for preparing polycarbazole derivative nanofibers

ActiveCN109137123BAvoid difficultiesEasy to manufactureNanotechnologyMonocomponent synthetic polymer artificial filamentNanofiberPerylene derivatives

The invention discloses a method for preparing a polycarbazole derivative nanofiber. The method comprises the following steps that surface treatment is carried out on a silicon chip; raw materials PCDTBT and PEO are added into a solvent to prepare a blended solution; the blended solution is placed on a heating stage until solute is dissolved; the treated silicon chip serves as a substrate, and a rotating coating machine is utilized to prepare blending film through a rotating coating method; and the blending film is washed and blow-dried with a nitrogen gun to obtain nanofibrous PCDTBT film. The method for preparing the polycarbazole derivative nanofiber has the advantages that the difficulty of conjugated macromolecular chain motion represented by PCDTBT is overcome, a method for preparinga conjugated macromolecular nanofiber simply and easily is provided, and the method is conductive to improving the efficiency of PCDTBT-based photoelectric device in the production practice.

Owner:ZHENGZHOU UNIV

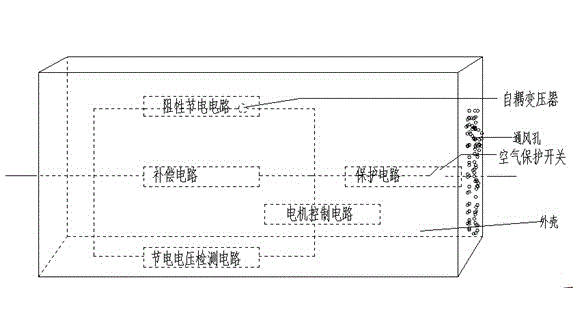

Energy-saving illumination voltage stabilizer

InactiveCN103338566ALower resistanceResistance is easy to adjustElectric light circuit arrangementEnergy saving control techniquesElectrical resistance and conductanceEngineering

The invention discloses an energy-saving illumination voltage stabilizer, which relates to the field of electrical engineering. The energy-saving illumination voltage stabilizer comprises a shell and a body, wherein the body is internally provided with a resistive power-saving circuit, a power-saving voltage detection circuit, an electric motor control circuit and a protection circuit, wherein the resistive power-saving circuit is connected with the power-saving voltage detection circuit and the electric motor control circuit in parallel and is connected with the protection circuit in series, the power-saving voltage detection circuit is connected with the electric motor control circuit and the protection circuit in series, the power-saving voltage detection circuit, the electric motor control circuit and the protection circuit adopt nanocarbon materials as circuit materials, the energy-saving illumination voltage stabilizer is internally provided with a compensation circuit, and the compensation circuit is respectively connected with the electric motor control circuit and the power-saving voltage detection circuit. The nanocarbon materials are used as the circuit materials due to good superconductivity and toughness of the nano materials, the resistance is small, the electric signal is strong, the energy-saving illumination voltage stabilizer is not likely to break, the cost is low, air pollution cannot be caused, energy-saving and environment-friendly effects are realized, the compensation circuit can be regulated according to a signal of the power-saving voltage detection circuit, the energy consumption can be reduced, the starting voltage can be regulated to be 231V, the stabilized voltage can be regulated to be 198V, and the service life of a lamp can be prolonged.

Owner:STATE GRID CORP OF CHINA +1

Method for preparing polycarbazole derivative nanofiber

ActiveCN109137123AAvoid difficultiesEasy to manufactureNanotechnologyMonocomponent synthetic polymer artificial filamentNanofiberNitrogen

The invention discloses a method for preparing a polycarbazole derivative nanofiber. The method comprises the following steps that surface treatment is carried out on a silicon chip; raw materials PCDTBT and PEO are added into a solvent to prepare a blended solution; the blended solution is placed on a heating stage until solute is dissolved; the treated silicon chip serves as a substrate, and a rotating coating machine is utilized to prepare blending film through a rotating coating method; and the blending film is washed and blow-dried with a nitrogen gun to obtain nanofibrous PCDTBT film. The method for preparing the polycarbazole derivative nanofiber has the advantages that the difficulty of conjugated macromolecular chain motion represented by PCDTBT is overcome, a method for preparinga conjugated macromolecular nanofiber simply and easily is provided, and the method is conductive to improving the efficiency of PCDTBT-based photoelectric device in the production practice.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com