Preparation method and application of MOF-based plant leaf friction nano-generator

A nanogenerator, plant blade technology, applied in triboelectric generators, coatings, etc., can solve problems such as low sensitivity, large sensor size, and limited application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

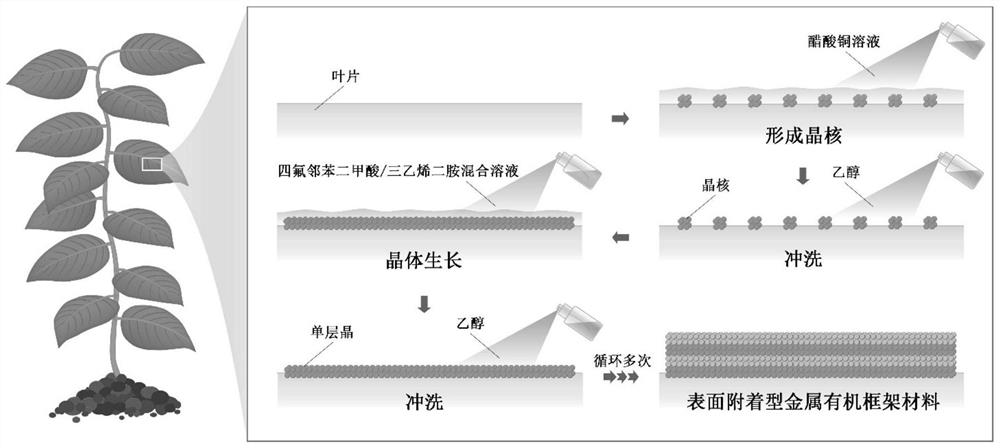

[0038] Preparation of MOF-based plant leaf triboelectric nanogenerators:

[0039] The leaves were washed alternately with ultrapure water and ethanol for 10 s. Weigh 100mg of copper acetate and dissolve it in 100mL of pure ethanol to prepare a concentration of 5mM copper acetate solution, weigh 24mg of tetrafluorophthalic acid and dissolve it in 100mL of pure ethanol to prepare a concentration of 1mM tetrafluorophthalic acid solution, weigh Dissolve 11.2mg of triethylenediamine in 100mL of pure ethanol to prepare a solution of triethylenediamine with a concentration of 1mM. 50 mL of tetrafluorophthalic acid solution and 50 mL of triethylenediamine solution were mixed respectively to obtain 100 mL of tetrafluorophthalic acid / triethylenediamine mixed solution with a concentration of 0.5 mM.

[0040] Subsequently, if figure 1As shown, put 100mL of 5mM copper acetate solution, 0.5mM tetrafluorophthalic acid / triethylenediamine mixed solution and pure ethanol into the watering can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com