Protective metal anode structure and preparation method thereof

A metal anode, protective technology, used in structural parts, active material electrodes, negative electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

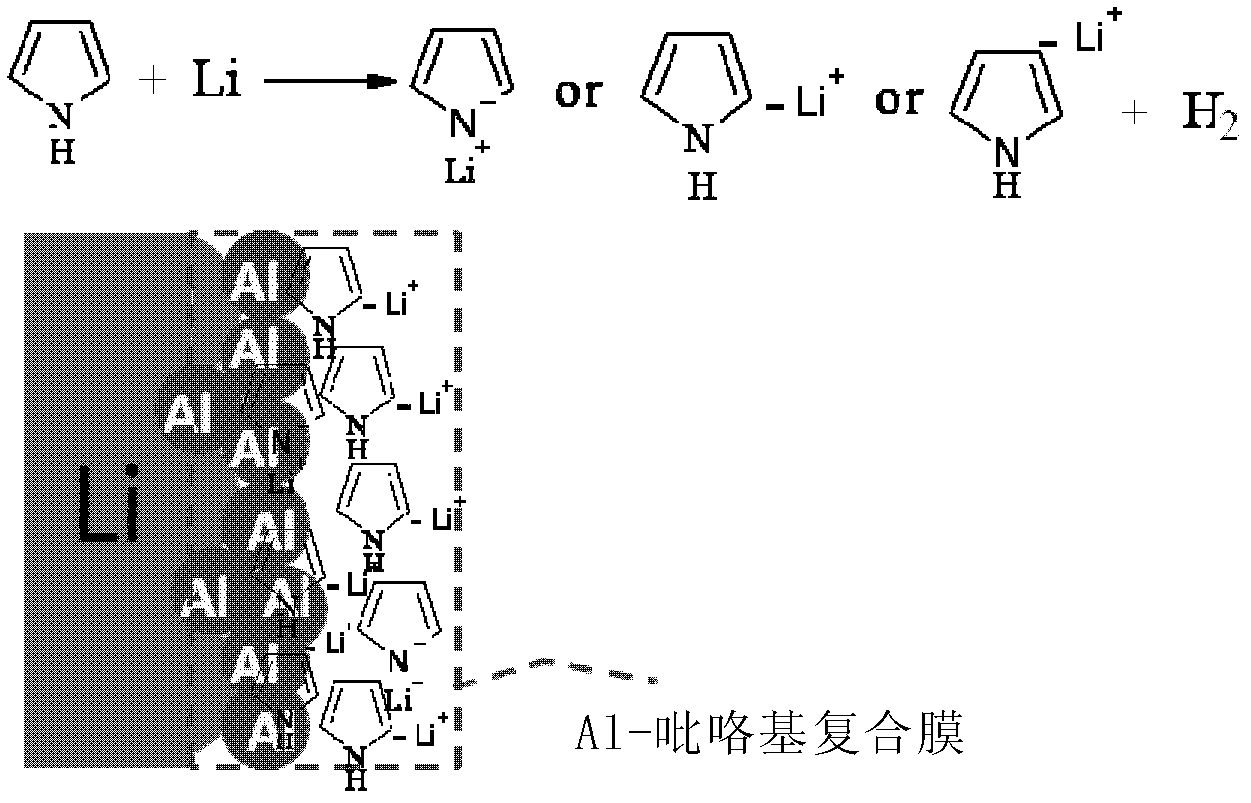

[0070] In the second aspect of the present invention, a kind of preparation method of the metal lithium electrode material of metal aluminum-pyrrole composite modification is provided (referring to figure 1 ) and the characterization of its electrochemical performance, including:

[0071] (1) Configure different concentrations (0.1-1M) of pyrrole and electrolyte (such as: 1M LiPF 6 / (EC+DMC)(w / w 1:1)) mixed solution;

[0072] (2) According to the stoichiometric proportioning, weigh aluminum trichloride of different quality, be made into aluminum trichloride (0.1-1M)-pyrrole (0.1-1M)-electrolyte (as: 1M LiPF 6 / (EC+DMC)(w / w1:1)) mixed solution;

[0073] (3) In an inert atmosphere or a vacuum environment, two pre-prepared pieces with a diameter of 14mm and a thickness of

[0074] The fresh lithium foil of 1-2mm is used as electrode, and the mixed solution among above-mentioned (2) is electrolytic solution, obtains from U.S. Celgard

[0075] The company's polypropylene film ...

Embodiment 1

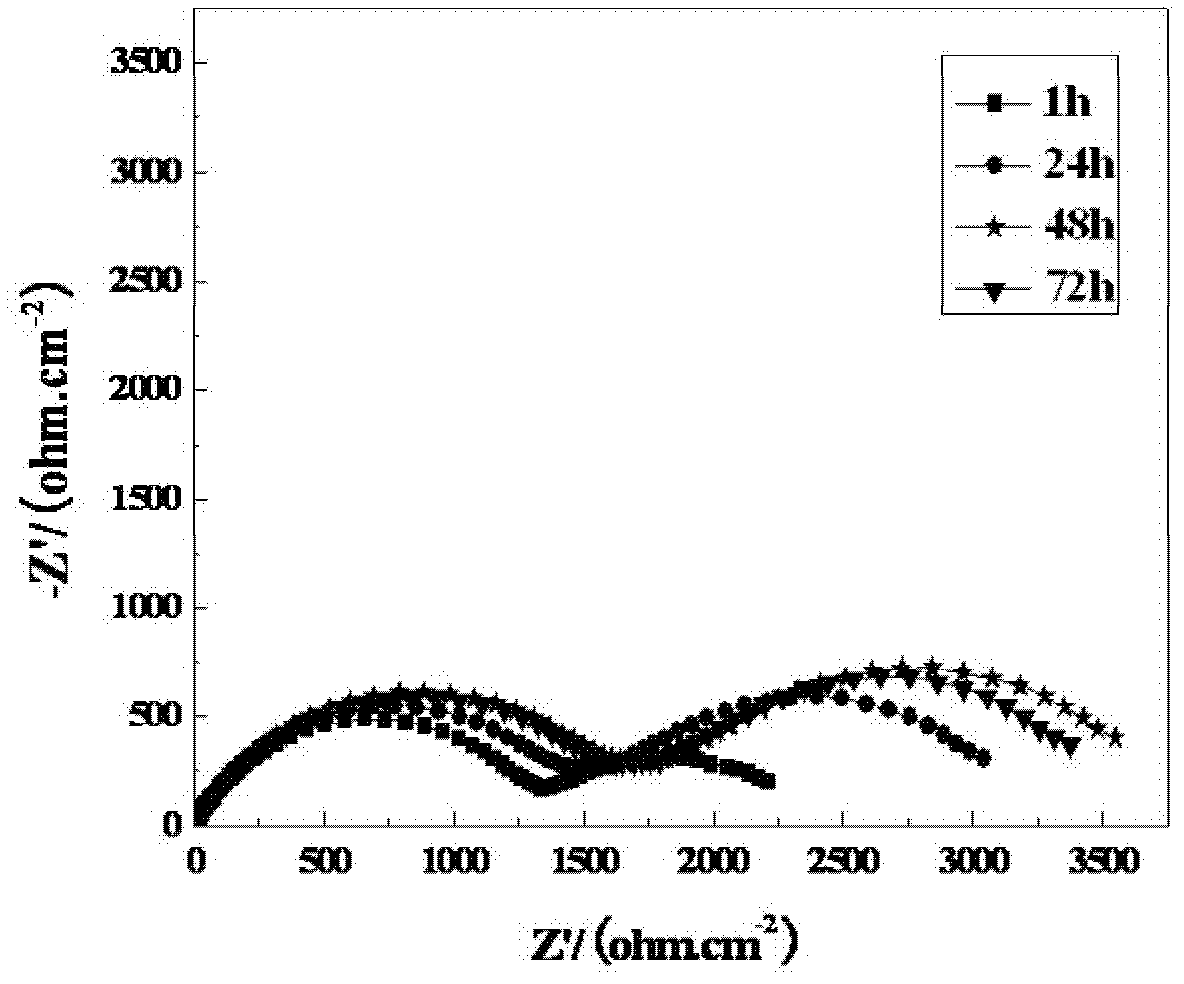

[0084] Adopting a metal lithium foil electrode with a diameter of 14mm and a thickness of 1-2mm, the polypropylene film obtained from U.S. Celgard Company is used as a diaphragm, and the electrolyte (1M LiPF 6 / (EC+DMC)(w / w 1:1)) mixed solution was used as the electrolyte, and the scan rate was 10mV / s, and the electrochemical impedance was tested as a function of time. Then, in an inert atmosphere or vacuum, use a pre-mirror-polished Cu sheet electrode of the same size as the working electrode, and other conditions are the same as above. After the battery is assembled, it is left to stand for 24 hours to perform a constant current charge-discharge cycle test. The results are shown in Table 1 below (see figure 2 with 6 ).

Embodiment 2

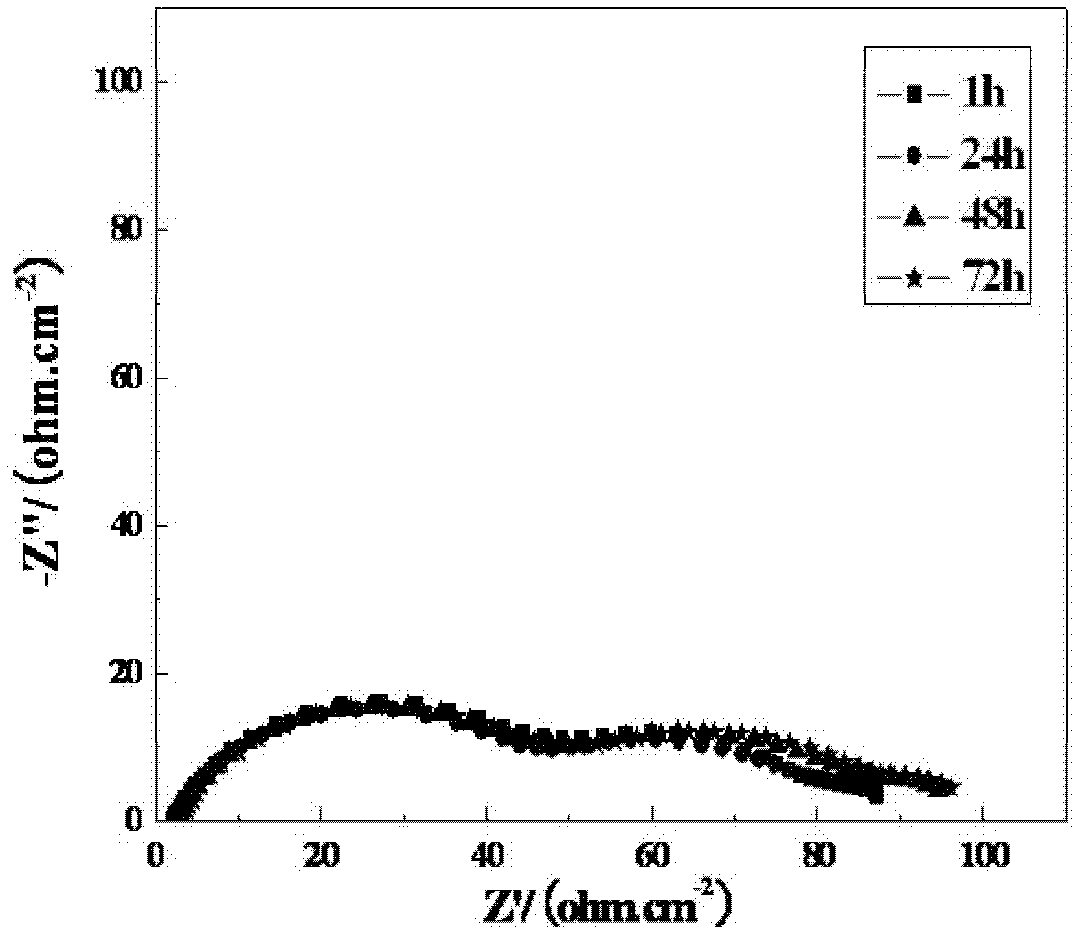

[0086] A metal lithium foil electrode with a diameter of 14mm and a thickness of 1-2mm is used, and the polypropylene film obtained from U.S. Celgard Company is used as a diaphragm, and pyrrole (0.1M) / electrolyte (1M LiPF 6 / (EC+DMC)(w / w 1:1)) mixed solution was used as the electrolyte, and the scan rate was 10mV / s, and the electrochemical impedance was tested as a function of time. Then, in an inert atmosphere or vacuum, use a pre-mirror-polished Cu sheet electrode of the same size as the working electrode, and other conditions are the same as above. After the battery is assembled, it is left to stand for 24 hours to perform a constant current charge-discharge cycle test. The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com