Lithium secondary cell

A lithium secondary battery and non-aqueous electrolyte technology, which can be applied to secondary batteries, dry batteries, battery electrodes, etc., and can solve problems such as the shedding of the mixture layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

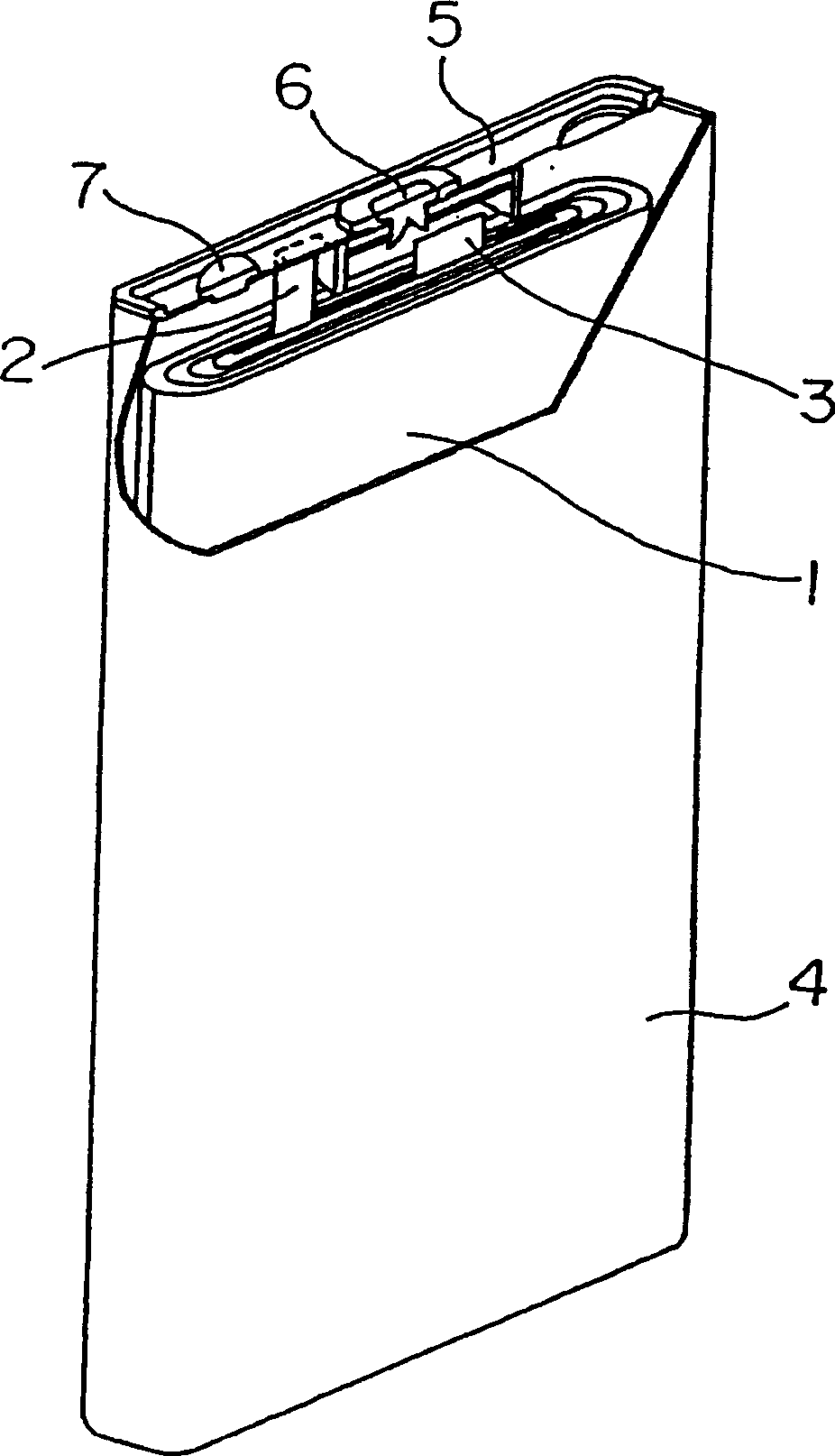

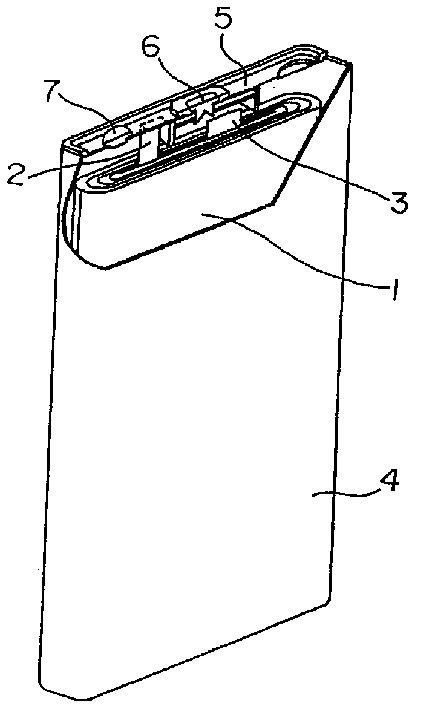

Image

Examples

Embodiment Construction

[0060] The present invention relates to a lithium secondary battery using a negative electrode formed by immobilizing an active material composed of a mixture of artificial graphite particles A and highly circular spherical graphite particles B on a copper core. The above-mentioned artificial graphite particle A is obtained by mixing and granulating the matrix material obtained by pulverizing the overall mesophase pitch and the pitch and / or thermosetting resin in a softened state, and carbonizing the granules at 700-1500°C, and then carbonizing them at 2500-2500°C. Particles obtained by graphitization at 3000°C.

[0061] In the method for producing artificial graphite particles A, the average particle diameter of the base material produced after pulverizing the bulk mesophase pitch is 7-20 μm, and the amount of pitch and / or thermosetting resin is 8-25 wt. share.

[0062] Adopt the present invention, because the graphite structure of the artificial graphite particle A as the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com