Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of silicon expansion, serious silicon agglomeration, poor cycle performance, etc., and achieve orderly arrangement, good dispersion, The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

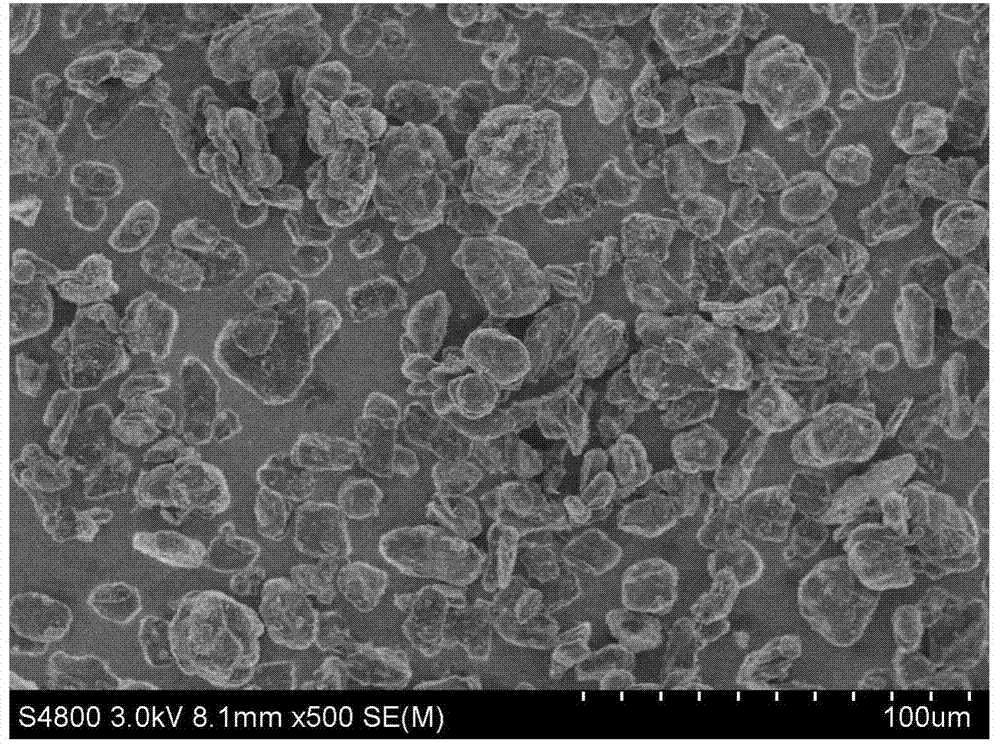

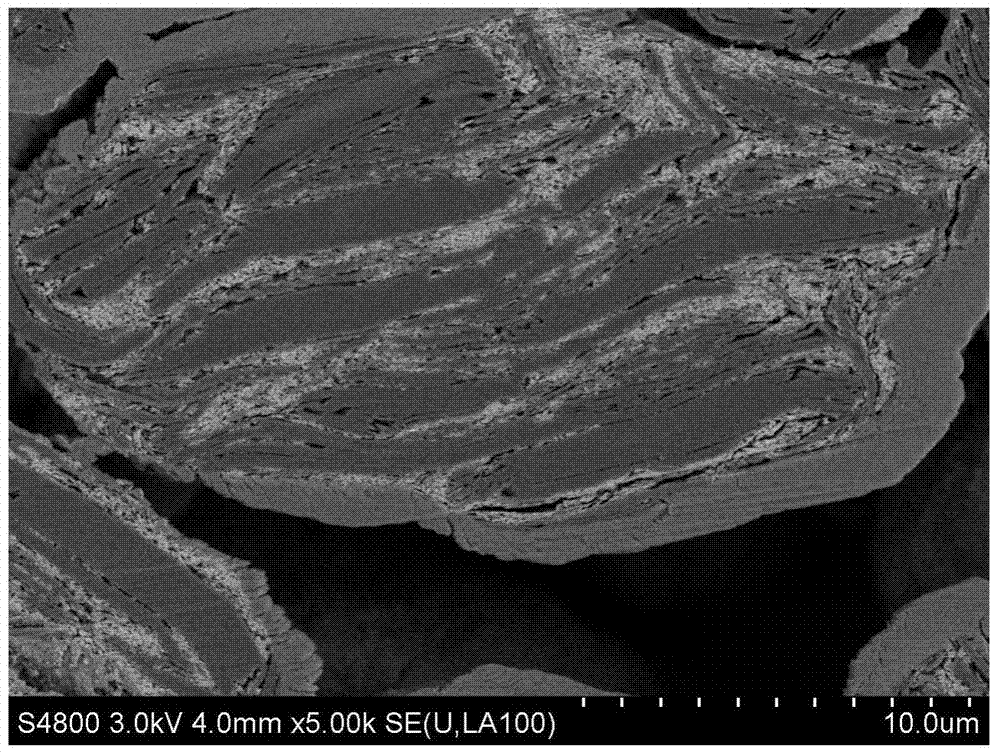

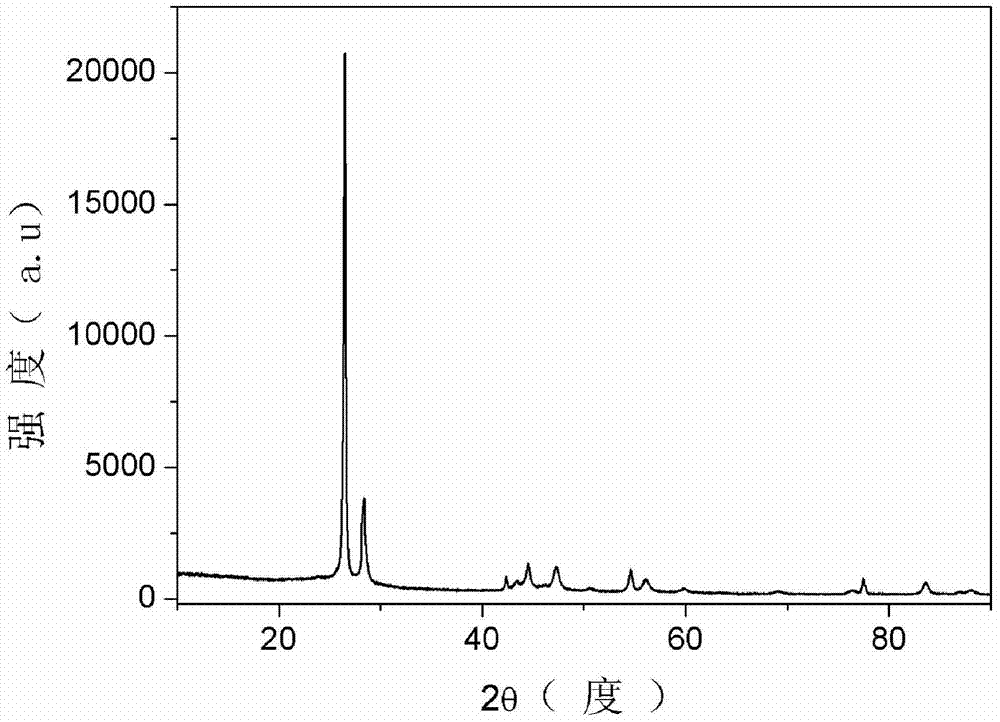

[0084] Spherical natural graphite is mechanically crushed to graphite particles with a median particle size of 5.0-15.0 μm, placed in a ball mill containing 4 mm silicon nitride balls and a propanol solvent, and ball milled to obtain a median particle size of 1.0 μm. ~10.0μm hollow graphite; the silicon raw material is air-pulverized to obtain silicon particles with a median particle size of 5.0-30.0μm, which are then placed in a sand mill containing 0.01mm tungsten carbide beads and methanol solvent for grinding. Obtain nano-silicon powder with a median particle size of 10-300nm; add the above-prepared nano-silicon powder and fatty acid polyethylene glycol ester to methanol at a mass ratio of 15:0.5, and ultrasonically stir for 0.5h to form uniformly dispersed nano-silicon Suspension; add hollow graphite (nano-silicon: hollow graphite mass ratio 15:50) to the suspension, stir for 2 hours at a stirring speed of 2000rpm, and dry to obtain the first precursor; add the first precu...

Embodiment 2

[0086] Mechanically crush flake natural graphite to graphite particles with a median particle size of 10.0-25.0 μm, place it in a ball mill containing 0.01mm silicon nitride balls and ethylene glycol solvent, and perform ball milling to obtain the median particle size Hollow graphite of 1.0-10.0 μm; mechanically pulverize silicon raw materials to obtain silicon particles with a median particle size of 5.0-40.0 μm, and then place them in a sand mill containing 0.02mm zirconia balls and ethylene glycol solvent Grinding in the medium to obtain nano-silicon powder with a median particle size of 10-400nm; add the above-prepared nano-silicon powder and polyetherimide to ethylene glycol at a mass ratio of 50:1, and ultrasonically stir for 1h to form a uniform Dispersed nano-silicon suspension; add hollowed graphite (nano-silicon: hollowed graphite mass ratio 50:30) to the suspension, stir for 5 hours at a stirring speed of 3000rpm, and dry to obtain the first precursor; the first prec...

Embodiment 3

[0088] Spherical artificial graphite is crushed by high-pressure grinding to graphite particles with a median particle size of 5.0-10.0 μm, placed in a ball mill containing 10 mm silicon nitride balls and acetone solvent, and ball milled to obtain a median particle size of 1.0 μm. ~10.0μm hollowed graphite; the silicon raw material is jet-milled to obtain silicon particles with a median particle size of 5.0-20.0μm, which are then placed in a sand mill containing 1mm silicon carbide beads and N-methylpyrrolidone solvent Grind to obtain nano-silicon powder with a median particle size of 50-500nm; add the above-prepared nano-silicon powder and polyacrylic acid to ethanol at a mass ratio of 1:10, and ultrasonically stir for 0.1h to form a uniformly dispersed nano-silicon suspension liquid; add hollowed graphite (nano-silicon: hollowed graphite mass ratio 1:90) to the suspension, stir for 1 hour at a stirring speed of 600rpm, and dry to obtain the first precursor; add the first prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com