Vinylidene fluoride-based resin film

A technology of vinylidene fluoride and resin film, which is applied in the direction of synthetic resin layered products, thin material processing, polyether adhesive, etc., can solve the problems of low wettability and poor performance, and achieve good dispersion and thermal stability Excellent performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

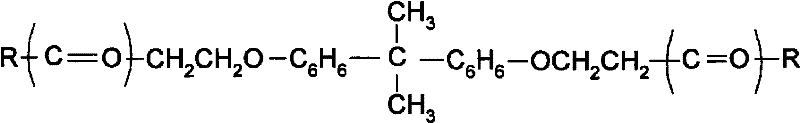

[0032] First, a vinylidene fluoride resin film (hereinafter also simply referred to as a resin film) according to a first embodiment of the present invention will be described. The resin film of this embodiment contains at least a resin component composed of a vinylidene fluoride resin and a methacrylate resin, titanium oxide, and a fatty acid ester of polyethylene glycol and / or its derivatives.

[0033] In addition, the titanium oxide compounded in the resin film of this embodiment is surface-treated with alumina and silica, and their total adhesion amount is 5 to 11 mass % with respect to the total mass of titanium oxide. In addition, the "total mass of titanium oxide" referred to here is a mass including alumina and silica adhered to the surface. Hereinafter, each component which comprises the resin film of this embodiment is demonstrated.

[0034] [Vinylidene fluoride resin]

[0035] Vinylidene fluoride resin is excellent in weather resistance and heat resistance, and is...

no. 2 approach

[0067] Next, a vinylidene fluoride-based resin film according to a second embodiment of the present invention will be described. The resin film of this embodiment is a multilayer film having two or more layers with different compositions, and contains vinylidene fluoride resin, methacrylate resin, and aluminum oxide and Silicon surface-treated titanium oxide, and fatty acid esters of polyethylene glycol and / or derivatives thereof.

[0068] [Resin composition mixing ratio]

[0069]The resin component in the resin film of the present embodiment is composed of the aforementioned vinylidene fluoride resin and methacrylate resin, and the compounding ratio thereof is vinylidene fluoride resin:methacrylate resin= 70:30 to 95:5, in the back layer, vinylidene fluoride resin:methacrylate resin=5:95 to 45:55 in terms of mass ratio. That is, in the resin film of this embodiment, the compounding ratio of a vinylidene fluoride resin and a methacrylate resin differs between a surface layer...

no. 1 Embodiment

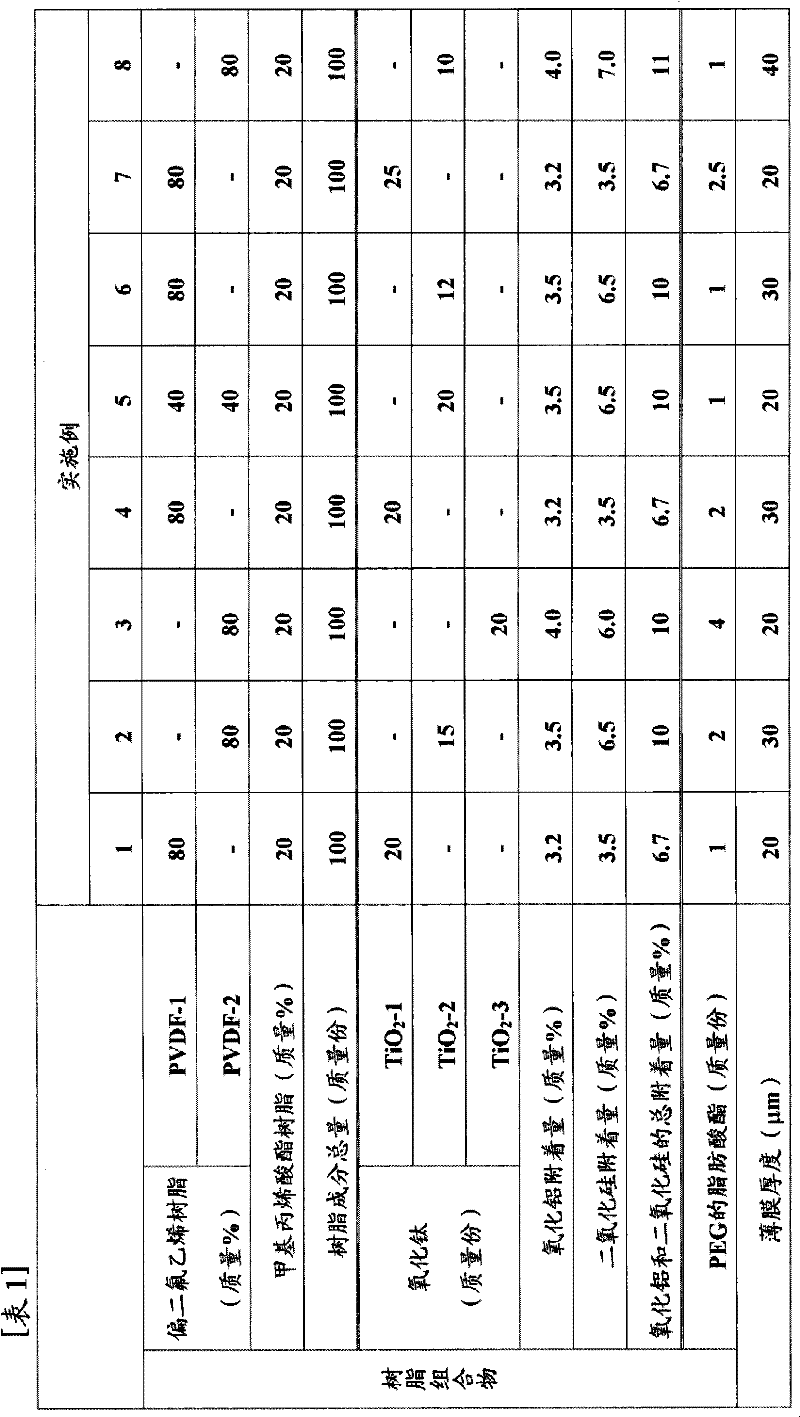

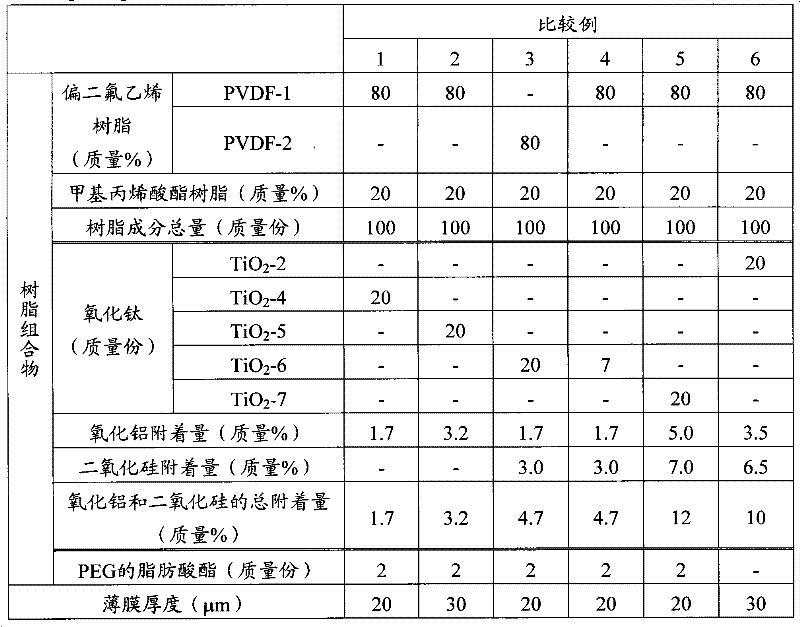

[0091] The effects of the present invention will be described below with examples and comparative examples of the present invention. First, as an example of the first embodiment of the present invention, the resin films of Examples 1 to 8 were produced from the resin compositions of the compositions shown in Table 1 below, and the pigment dispersibility and thermal stability thereof were evaluated.

[0092]

[0093] Specifically, first, vinylidene fluoride resin, methacrylate resin, titanium oxide, and fatty acid ester of polyethylene glycol (PEG) were mixed with a tumbler according to the compounding ratio shown in Table 1 above. blend. Then, by diameter A twin-screw extruder was used for kneading to obtain a compound (resin composition). Next, use the diameter The single-screw extruder was equipped with a film-making machine with a slit of 0.4mm and a width of 400mm with a hanger-type die to produce a resin film with the thickness shown in Table 1 above.

[0094] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com