Modified phosphorus-nitrogen type flame retardant and preparation method thereof

A flame retardant and modification technology, which is applied in the field of modified phosphorus-nitrogen flame retardant and its preparation, can solve the problems of easy blooming, easy migration, poor compatibility, etc., and achieve the effect of good dispersion and difficult agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

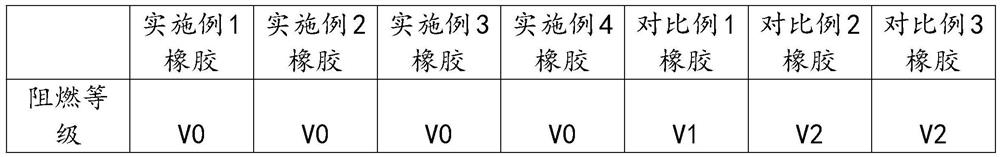

Examples

Embodiment 1

[0028] A modified phosphorus nitrogen type flame retardant, made by the following method:

[0029] Step S1. Add pentaerythritol into a three-necked flask, place it in an ice-water bath, stir at a speed of 100r / min for 30min, add phosphorus oxychloride dropwise while stirring, control the dropping time to 15min, and use a mass fraction of 20% during the dropping process. % sodium hydroxide aqueous solution to absorb the tail gas, stir at a constant speed for 30 minutes after the dropwise addition, then raise the temperature to 60°C, stir at a constant speed at this temperature for 2 hours, heat up to 100°C, reflux until no hydrogen chloride is produced, cool and filter with suction after the reaction , the filter cake was washed three times with chloroform and absolute ethanol, and then transferred to a vacuum drying oven with a vacuum degree of -0.10 MPa, and dried at 50°C for 10 hours to obtain the first product. In step S1, pentaerythritol and three The weight ratio of phosp...

Embodiment 2

[0036] A modified phosphorus nitrogen type flame retardant, made by the following method:

[0037] Step S1. Add pentaerythritol into a three-necked flask, place it in an ice-water bath, stir at a speed of 100r / min for 30min, add phosphorus oxychloride dropwise while stirring, control the dropping time to 15min, and use a mass fraction of 20% during the dropping process. % sodium hydroxide aqueous solution to absorb the tail gas, stir at a constant speed for 30 minutes after the dropwise addition, then raise the temperature to 60°C, stir at a constant speed at this temperature for 2 hours, heat up to 100°C, reflux until no hydrogen chloride is produced, cool and filter with suction after the reaction , the filter cake was washed three times with chloroform and absolute ethanol, and then transferred to a vacuum drying oven with a vacuum degree of -0.10 MPa, and dried at 50°C for 10 hours to obtain the first product. In step S1, pentaerythritol and three The weight ratio of phosp...

Embodiment 3

[0044] A modified phosphorus nitrogen type flame retardant, made by the following method:

[0045] Step S1. Add pentaerythritol into a three-necked flask, place it in an ice-water bath, stir at a speed of 100r / min for 30min, add phosphorus oxychloride dropwise while stirring, control the dropping time to 15min, and use a mass fraction of 20% during the dropping process. % sodium hydroxide aqueous solution to absorb the tail gas, stir at a constant speed for 30 minutes after the dropwise addition, then raise the temperature to 60°C, stir at a constant speed at this temperature for 2 hours, heat up to 100°C, reflux until no hydrogen chloride is produced, cool and filter with suction after the reaction , the filter cake was washed three times with chloroform and absolute ethanol, and then transferred to a vacuum drying oven with a vacuum degree of -0.10 MPa, and dried at 50°C for 10 hours to obtain the first product. In step S1, pentaerythritol and three The weight ratio of phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com