Device and method for polycondensation of polyol by using cyclic compound

A technology for cyclic compounds and polyols, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc. problems such as low efficiency, to achieve the effect of improving efficiency and improving product molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

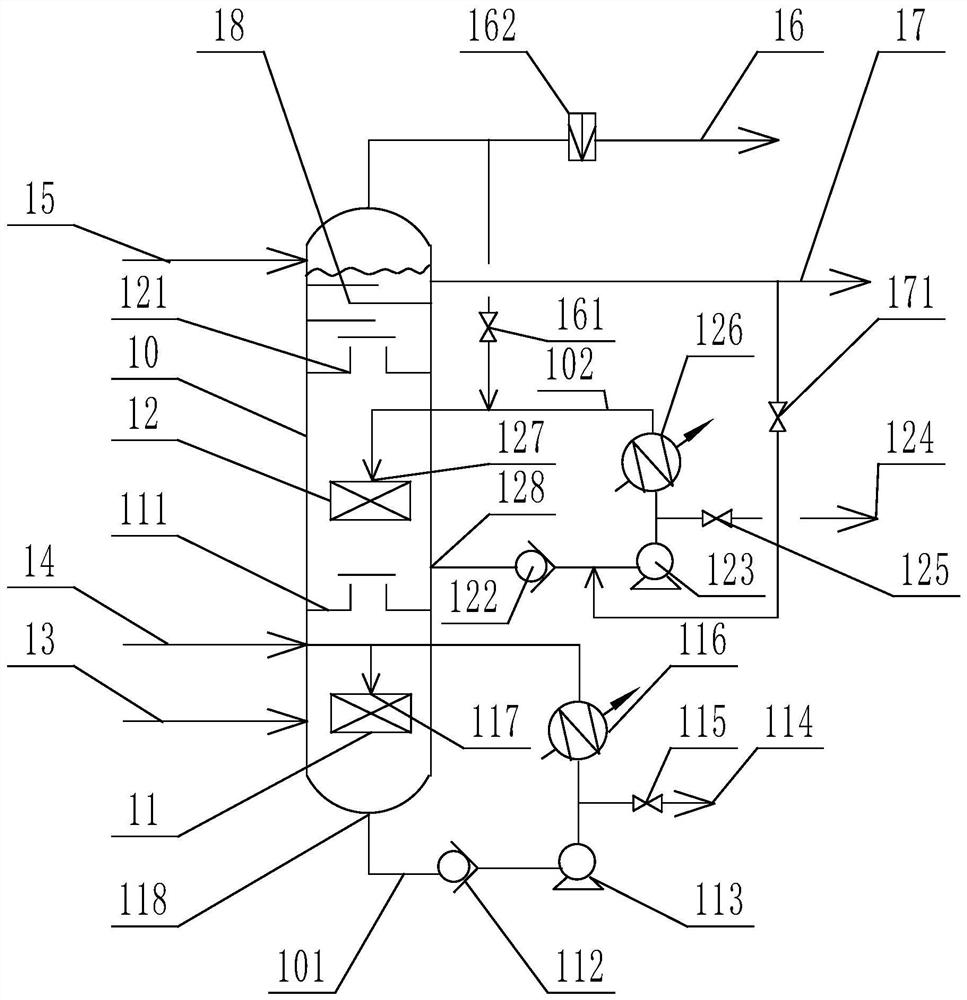

[0054] refer to figure 1 Shown is a schematic structural diagram of a device for polycondensation of polyols using cyclic compounds provided by the present invention. The device includes a reactor 10, the reactor 10 is divided into bottom, middle and top three parts, the bottom and the middle are separated by the first one-way channel 111, and the middle and the top are separated by the second one-way channel 121. In this embodiment, the cyclic compound is selected as propylene oxide, and the polyol is ethylene glycol.

[0055] First, a first micro-interface generator 11 is provided at the bottom of the reaction kettle 10 . The first micro-interface generator 11 is arranged on the center line of the reaction kettle 10 . The polyol pipeline 13 enters the reactor 10 through the side wall at the bottom of the reactor 10, and ethylene glycol is passed into the reactor 10, and the cyclic compound pipeline 14 also enters the reactor 10 through the side wall at the bottom of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com