Copper-plated graphene aluminum-based composite material and preparation method thereof

A technology of aluminum-based composite materials and copper-coated graphene, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc. problem, to achieve the effect of strong designability, simple operation and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The invention provides a method for preparing a copper-plated graphene aluminum-based composite material, which includes the following steps:

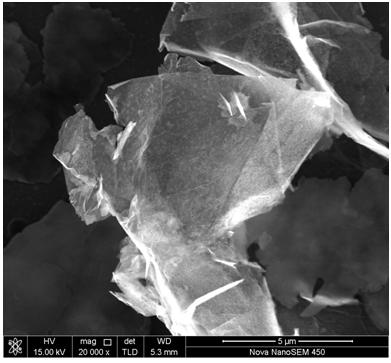

[0038]S1: subjecting the surface of the graphene powder to solution copper plating treatment to prepare copper-plated graphene powder;

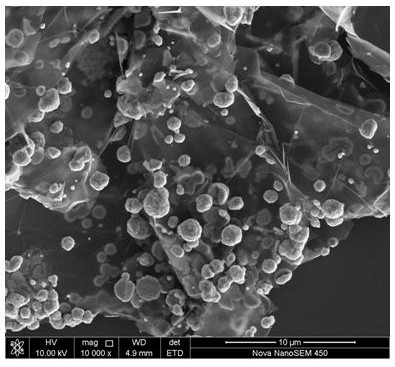

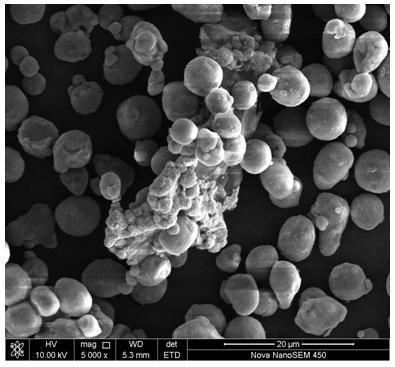

[0039]S2: Using the electrostatic self-assembly method to mix the copper-plated graphene powder and aluminum powder prepared in step S1, specifically including the following steps: adding 9.99g spherical aluminum powder to 6g / L cetyltrimethyl bromide In ammonium aqueous solution, magnetically stirred for 2h to obtain a positively charged spherical aluminum powder slurry C; add 0.01g copper-plated graphene powder to 15g / L sodium dodecylbenzenesulfonate aqueous solution, and magnetically stirred for 2h , Obtain copper-plated graphene slurry D with negative charge on the surface; drop slurry D into slurry C, stir it magnetically for 2 hours, and adsorb the negatively-charged copper-plated graphene on the On th...

Embodiment 2

[0042]The invention provides a method for preparing a copper-plated graphene aluminum-based composite material, which includes the following steps:

[0043]S1: subjecting the surface of the graphene powder to solution copper plating treatment to prepare copper-plated graphene powder;

[0044]S2: Using electrostatic self-assembly method to mix the copper-plated graphene powder and aluminum powder prepared in step S1, specifically including the following steps: adding 9.98g of spherical aluminum powder to 6g / L of cetyltrimethyl bromide In the ammonium aqueous solution, magnetically stirred for 2h to obtain a positively charged spherical aluminum powder slurry C; add 0.02g copper-plated graphene powder to 15g / L sodium dodecylbenzene sulfonate aqueous solution, and magnetically stirred for 2h , Obtain copper-plated graphene slurry D with negative charge on the surface; drop slurry D into slurry C, stir it magnetically for 2 hours, and adsorb the negatively-charged copper-plated graphene on th...

Embodiment 3

[0047]The invention provides a method for preparing a copper-plated graphene aluminum-based composite material, which includes the following steps:

[0048]S1: subjecting the surface of the graphene powder to solution copper plating treatment to prepare copper-plated graphene powder;

[0049]S2: Using electrostatic self-assembly method to mix the copper-plated graphene powder and aluminum powder prepared in step S1, specifically including the following steps: adding 9.97g spherical aluminum powder to 6g / L cetyltrimethyl bromide In ammonium aqueous solution, magnetically stirred for 2h to obtain a positively charged spherical aluminum powder slurry C; add 0.03g copper-plated graphene powder to 15g / L sodium dodecylbenzene sulfonate aqueous solution, and magnetically stirred for 2h , Obtain copper-plated graphene slurry D with negative charge on the surface; drop slurry D into slurry C, stir it magnetically for 2 hours, and adsorb the negatively-charged copper-plated graphene on the On the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com