Glass fiber reinforced PPS-CNT (polyphenylene sulfide-carbon nano tube) conductive composite and preparation method thereof

A conductive composite material and glass fiber technology, which is applied in the field of glass fiber reinforced PPS-CNT conductive composite material and its preparation, can solve the problems of poor surface gloss, high equipment process requirements, unstable conductivity, etc., and achieve simple production process Controllable, good surface gloss, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

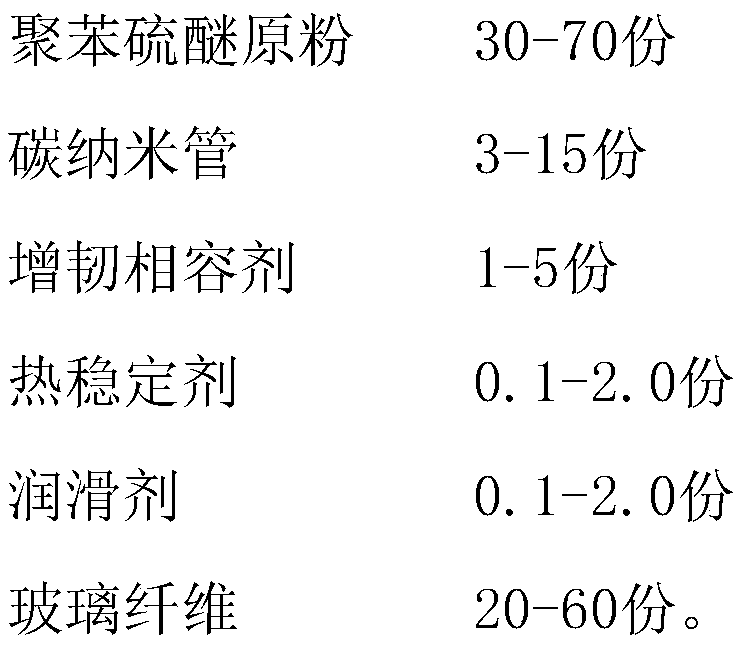

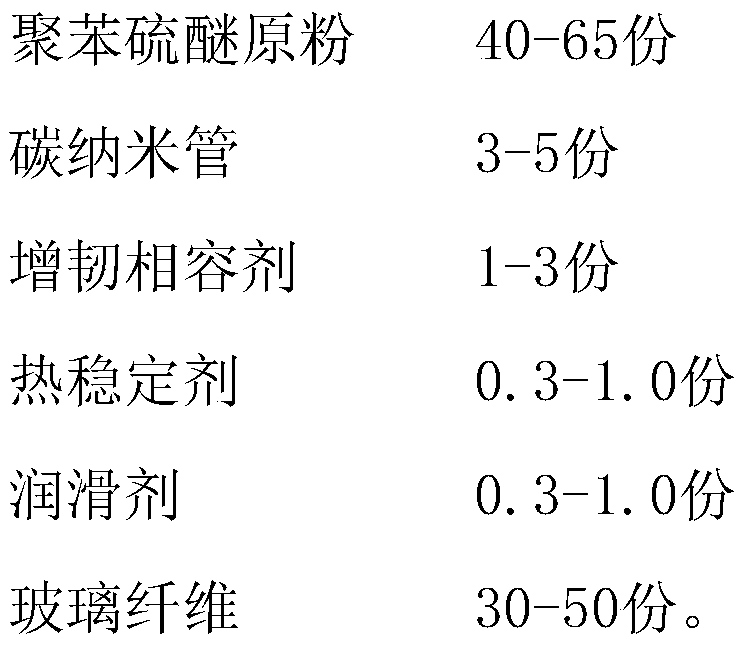

Method used

Image

Examples

Embodiment 1

[0040] Select the following raw materials in parts by weight: 53 parts of polyphenylene sulfide raw powder (1150C), 4 parts of CNT (CP1002M), 0.3 parts of heat stabilizer (GX2921), 2 parts of compatibilizer (SEBS-g-GMA), lubricating (TAF: 4-7081=1:1) 0.7 parts, mixed in a medium-speed mixer for 5 minutes, then blended with 40 parts of glass fiber (443R), extruded through a twin-screw extruder with a melting temperature of 250-300 ° C out, granulated, and made glass fiber reinforced PPS-CNT conductive composite material. Among them, the process conditions of the twin-screw extruder are: the temperature of the first zone is 250°C, the temperature of the second zone is 300°C, the temperature of the third zone is 300°C, the temperature of the fourth zone is 300°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 280°C. ℃, the temperature in the seventh zone is 270 ℃, the temperature in the eighth zone is 270 ℃, the temperature in the ninth zone ...

Embodiment 2

[0042] Select the following raw materials in parts by weight: 52 parts of polyphenylene sulfide raw powder (1150C), 4 parts of CNT (CP1002M), 0.3 parts of heat stabilizer (GX2921), 3 parts of compatibilizer (SEBS-g-GMA), lubricating (TAF: 4-7081=1:1) 0.7 parts, mixed in a medium-speed mixer for 5 minutes, then blended with 40 parts of glass fiber (443R), extruded through a twin-screw extruder with a melting temperature of 250-300 ° C out, granulated, and made glass fiber reinforced PPS-CNT conductive composite material. Among them, the process conditions of the twin-screw extruder are: the temperature of the first zone is 250°C, the temperature of the second zone is 300°C, the temperature of the third zone is 300°C, the temperature of the fourth zone is 300°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 280°C. ℃, the temperature in the seventh zone is 270 ℃, the temperature in the eighth zone is 270 ℃, the temperature in the ninth zone ...

Embodiment 3

[0044] Select the following raw materials in parts by weight: 52 parts of polyphenylene sulfide raw powder (1150C), 4 parts of CNT (CP1002M), 0.3 parts of heat stabilizer (GX2921), 3 parts of compatibilizer (SEBS-g-GMA), lubricating (TAF: 4-7081=1:1) 0.7 parts, mixed in a medium-speed mixer for 5 minutes, then blended with 30 parts of glass fiber (443R), and extruded through a twin-screw extruder with a melting temperature of 250-300 ° C out, granulated, and made glass fiber reinforced PPS-CNT conductive composite material. Among them, the process conditions of the twin-screw extruder are: the temperature of the first zone is 250°C, the temperature of the second zone is 300°C, the temperature of the third zone is 300°C, the temperature of the fourth zone is 300°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 280°C. ℃, the temperature in the seventh zone is 270 ℃, the temperature in the eighth zone is 270 ℃, the temperature in the ninth z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com