High-quality graphene and preparation method thereof

A graphene, high-quality technology, applied in the field of graphene, can solve the problems of inability to obtain high-conductivity graphene films, unfavorable energy-saving and consumption-reducing flexible conductive films, and high cost of hydrazine hydrate, achieving less impurities, good dispersibility, The effect of excellent electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

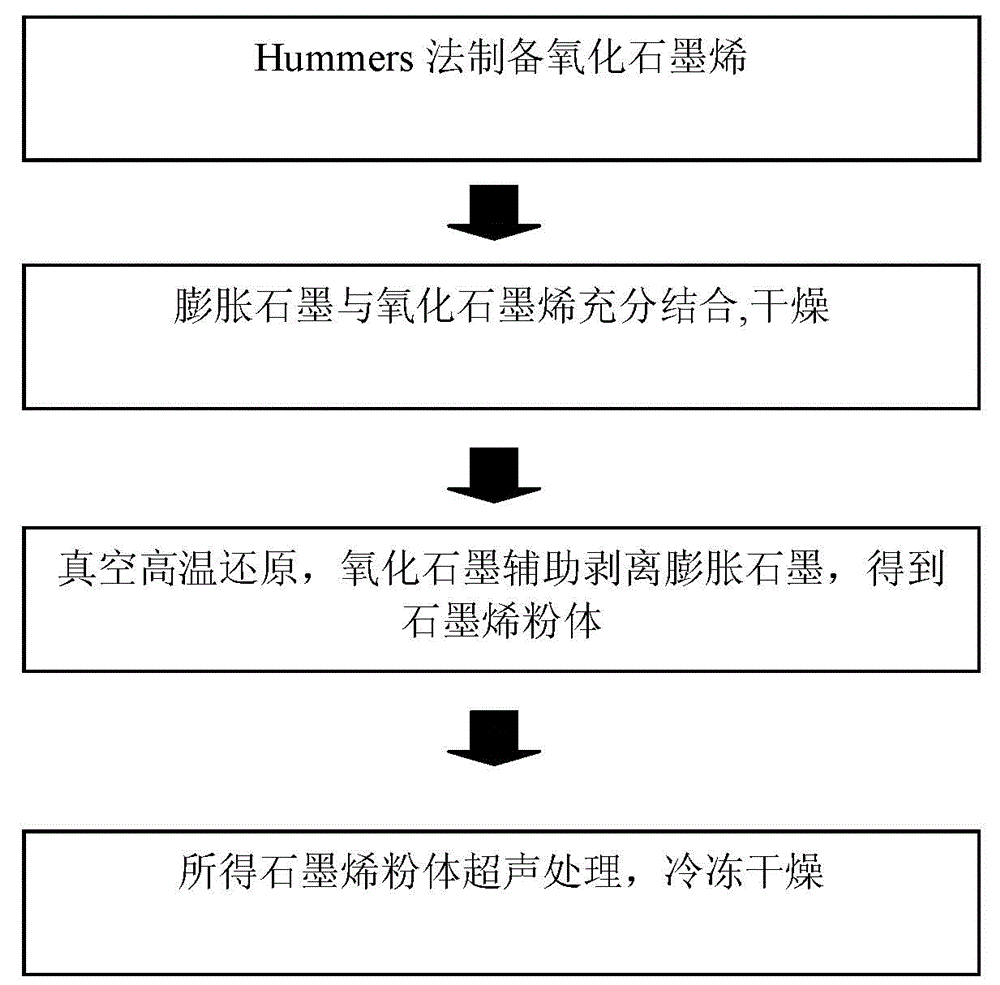

[0032] The method for preparing high-quality graphene of the present invention uses graphene oxide as an auxiliary substance to wrap and embed expanded graphite sheets, and utilizes the reaction force of graphite oxide during high-temperature expansion and reduction to assist in stripping the expanded graphite to prepare graphene. At the same time, high-quality graphene can also be prepared in combination with ultrasonic exfoliation in a solvent.

[0033] figure 1 A flowchart showing graphene oxide-assisted exfoliation of expanded graphite to prepare high-quality graphene according to one embodiment of the preparation method of the present invention. The following combination figure 1 This embodiment will be specifically described.

[0034] In this embodiment, graphene oxide as a raw material can be prepared by the Hummers method. However, it should be understood that in the present invention, the source of graphene oxide is not limited, for example, it can also be purchase...

Embodiment 1

[0051] refer to figure 1 , figure 1 The process flow diagram showing the preparation method for preparing graphene according to the embodiment of the present invention includes the following steps.

[0052] The first step is to prepare graphite oxide: the average particle size of graphite powder in this example is 325 mesh. Graphene oxide (GO) was synthesized by the Hummers method. 2g graphite powder, 1g NaNO 3 Mix well with 230ml concentrated sulfuric acid in an ice-water bath, slowly add 6g KMnO 4 . Then the temperature was raised to 35°C, and after stirring for 30 minutes, 92 mL of deionized water was added, and the temperature was raised to 98°C for 15 minutes to react. After that, add 280mL water to it to dilute, and wash with 5mL30%H 2 o 2 Neutralize excess KMnO 4 . The color of the mixed solution was brownish yellow, and it was filtered while hot, washed repeatedly with deionized water until neutral, and GO was obtained by ultrasonication.

[0053] The second ...

Embodiment 2

[0059] The preparation process steps of graphene are as follows.

[0060] The first step is to prepare graphite oxide: the average particle size of graphite powder in this example is 800 mesh. GO was synthesized by the Hummers method. As in Example 1.

[0061] The second step is the embedded wrapping of graphite oxide to expanded graphite: add 1g of expanded graphite to 150ml of graphene oxide solution with a mass fraction of 8mg / ml, stir for 5h to fully combine expanded graphite with graphene oxide, and make graphene oxide embedded in the voids of expanded graphite. The mixture was then dried at 80°C to a block.

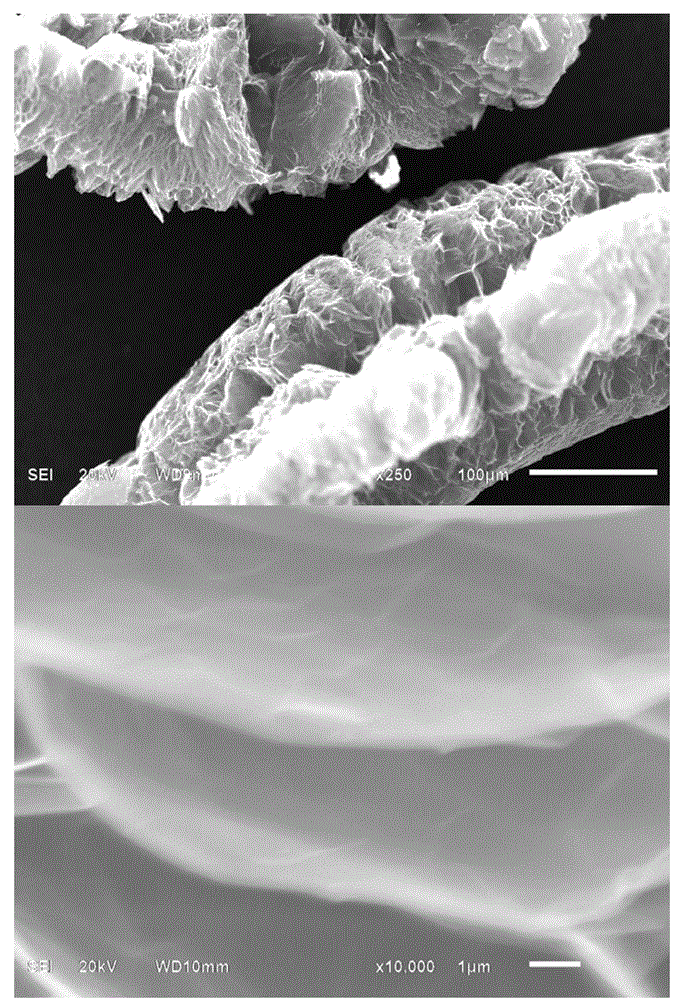

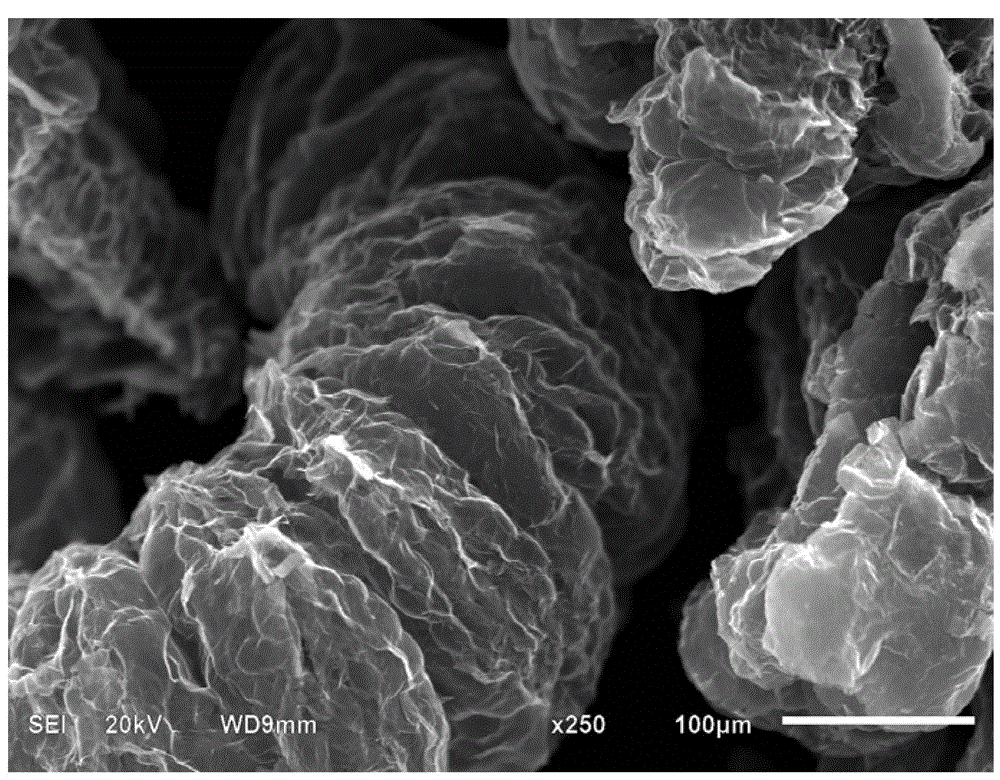

[0062] The third step, graphene oxide-assisted exfoliation of expanded graphite to prepare graphene: the above-mentioned dried product was treated at a high temperature of 800° C. for 10 minutes to obtain a fluffy graphene powder. Its SEM photo see Figure 4 .

[0063] The fourth step, ultrasonic treatment: disperse 1 g of the obtained graphene powder in 200 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com