Graphene oxide-epoxidized styrene butadiene rubber compound, preparation method thereof and vulcanized rubber

A technology of rubber compound and epoxidized butyl, which is applied in the local field, can solve problems such as affecting rubber properties and complex process, and achieve the effect of good tensile strength at break and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a kind of preparation method of graphene oxide-epoxidized styrene butadiene rubber composite, the method comprises:

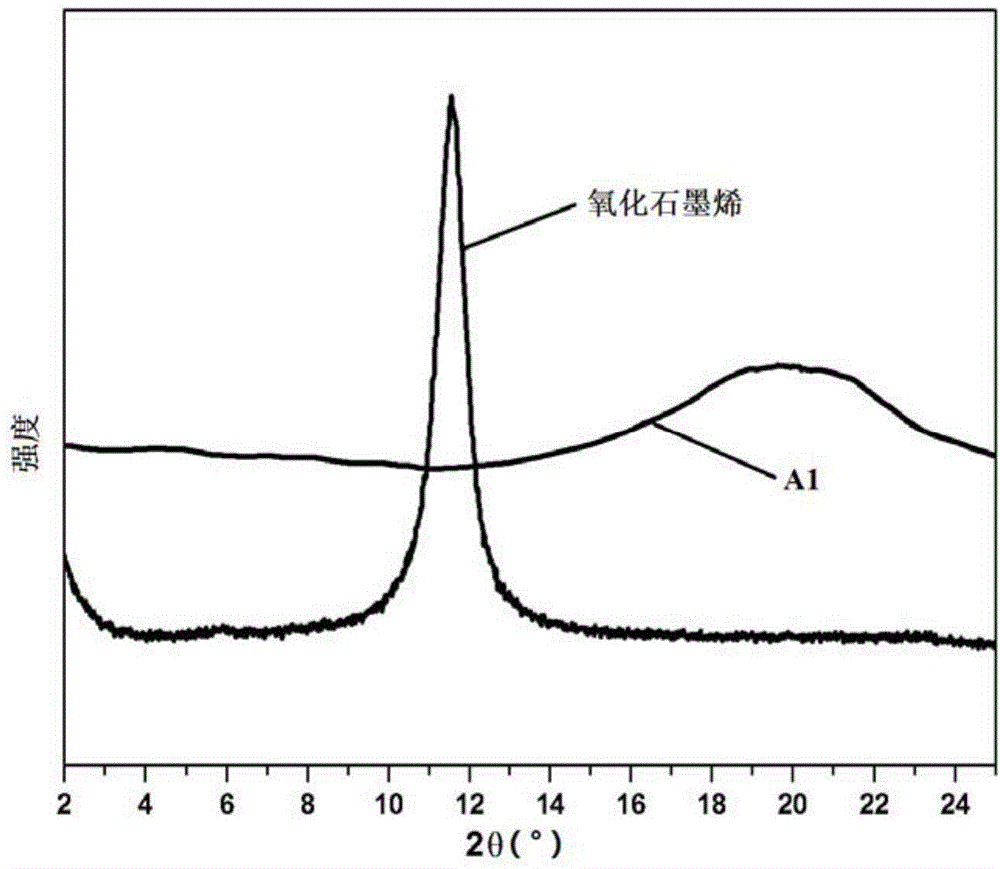

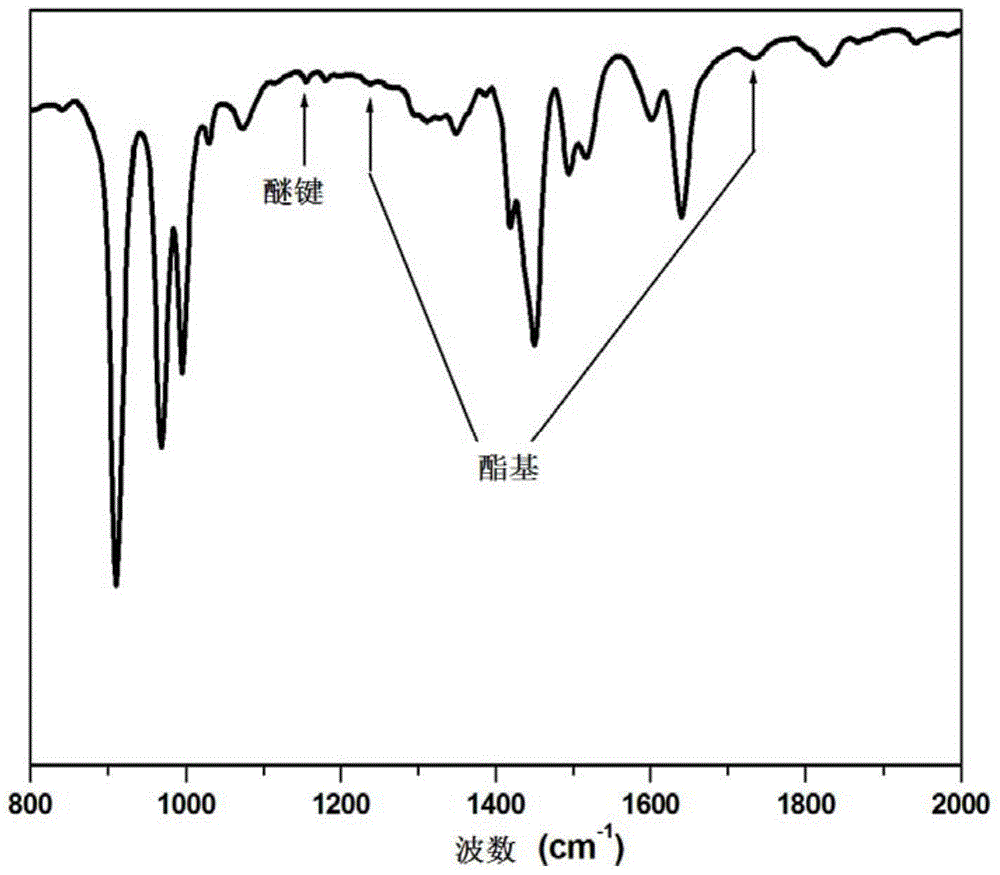

[0030] Kneading a mixture containing graphene oxide and epoxidized styrene-butadiene rubber; the kneading temperature is above 50°C to less than 110°C; in the mixture, relative to 100 parts by weight of the epoxidized styrene-butadiene rubber , the content of the graphene oxide is 0.1-15 parts by weight; the epoxidized styrene-butadiene rubber is obtained by epoxidizing styrene-butadiene rubber, the number-average molecular weight of the styrene-butadiene rubber is 100000-400000, and the molecular weight distribution The index is 1-3; based on the total weight of the styrene-butadiene rubber, the content of structural units formed by styrene is 15-40% by weight, and the content of structural units formed by butadiene is 60-85% by weight ; Based on the total weight of the structural units formed by butadiene in the styr...

preparation example 1

[0054] This preparation example is used to illustrate the preparation of solution-polymerized styrene-butadiene rubber and epoxidized styrene-butadiene rubber.

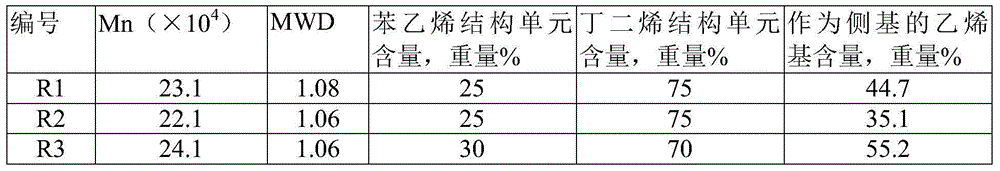

[0055] Replace the 5L polymerization reactor with high-purity nitrogen for 3 times, and add 2300 grams of cyclohexane and n-hexane mixed solvent into the reactor under the protection of high-purity nitrogen (the weight ratio of cyclohexane to n-hexane is 80:20) , 328 grams of butadiene, 110 grams of styrene, and 1.0 mL of tetrahydrofurfuryl alcohol ethyl ether as a structural regulator. The reaction kettle was heated to 50°C, and 15 mL of n-butyllithium (diluted to a concentration of 0.23M with a mixed solvent of cyclohexane and n-hexane) was added to initiate the polymerization reaction. After 30 minutes of polymerization reaction, 0.5 mL of terminator isopropanol was added, and after 5 minutes of reaction, 0.4% by weight of the total amount of butadiene and styrene was added as an anti-aging agent (purchased from Be...

preparation example 2

[0059] This preparation example is used to illustrate the preparation of solution-polymerized styrene-butadiene rubber and epoxidized styrene-butadiene rubber.

[0060] According to the method of Preparation Example 1, the difference is that "structure regulator tetrahydrofurfuryl alcohol ethyl ether 0.5mL" is used instead of "structure regulator tetrahydrofurfuryl alcohol ethyl ether 1.0mL". Polymerize to obtain styrene-butadiene rubber R2.

[0061] The structural parameters of the obtained styrene-butadiene rubber R2 were measured, and the results are shown in Table 1.

[0062] Styrene butadiene rubber R2 is epoxidized to obtain epoxidized styrene butadiene rubber ER2. The degree of epoxidation of ER2 was calculated to be 11.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com