Production technology of PVC heat shrinkage film packaging bag for tobacco and cigarette

A heat-shrinkable film and production process technology, which is applied in the field of heat-shrinkage production process to achieve uniform shrinkage, reasonable ratio of raw materials, and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

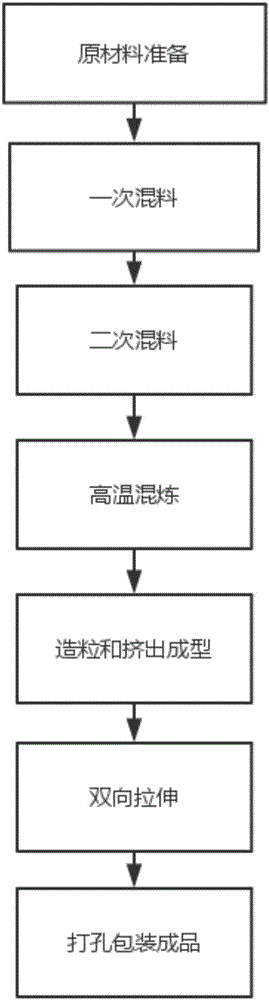

[0022] Such as figure 1 As shown, a kind of production technology of the PVC heat-shrinkable film packaging bag that is used for tobacco cigarette of the present embodiment is characterized in that, comprises following processing step:

[0023] (1) Preparation of raw materials: The raw materials for the production of this PVC heat shrinkable film include the following components, in parts by weight: 80 parts of PVC resin powder, 2 parts of NCP-2 auxiliary agent, 4 parts of glyceryl monostearate, adipic acid 3 parts fat, 12 parts talcum powder, 4 parts Houttuynia cordata extract, 3 parts ESC-1010 antioxidant;

[0024] (2) Primary mixing: put PVC resin powder, NCP-2 additives glyceryl monostearate, adipate and talcum powder in the raw materials and stir in a blender at a stirring temperature of 70°C and a rotating speed of 80rpm. Wherein the stirring time length is 20min;

[0025] (3) Secondary mixing: add Houttuynia cordata extract and antioxidant to the mixed material obtain...

Embodiment 2

[0030] Embodiment 2: all the other are the same as Example 1, except that the duration of stirring in the step (2) is 25min, the stirring temperature is 75°C, and the rotating speed is 70rpm, and the duration of stirring in the step (3) is 12min. The temperature is 90°C, the rotating speed is 180rpm, and the reaction time of the reactor in the step (4) is 1.5h. In the step (5), the material is cooled to 30°C through the cooling air ring of the double tuyere, and the step (6) The transverse stretching ratio is 6, the longitudinal stretching ratio is 6.5, and the hole diameter of the perforated holes is 2.5cm.

Embodiment 3

[0031] Embodiment 3: all the other are the same as Example 1, the difference is that the duration of stirring in the step (2) is 30min, the stirring temperature is 80°C, and the rotating speed is 80rpm, and the duration of stirring in the step (3) is 15min, stirring The temperature is 100°C, the rotating speed is 160rpm, and the reaction time of the reactor in the step (4) is 2h. In the step (5), the material is cooled to 40°C through the cooling air ring of the double tuyere. In the step (6), The transverse stretching ratio is 7, the longitudinal stretching ratio is 6, and the hole diameter of the perforated holes is 2.5 cm.

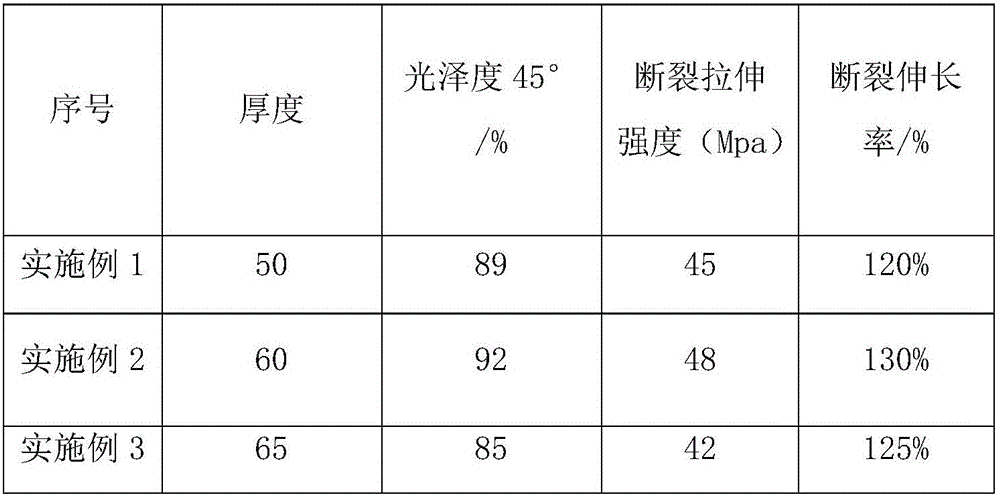

[0032] After the above process steps, the PVC heat shrinkable film sample was taken out, and the following data were obtained:

[0033]

[0034] From the above data, it can be seen that the product obtained by the present invention can maintain the characteristics of large heat shrinkable film elongation, good self-adhesiveness and high transparency,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com