Production technology of high-toughness high-impact strength heat-shrinkage film packaging bag

A technology of heat shrinkable film and production process, which is applied in the field of plastic products, can solve problems such as insufficient strength, graying, and surface blooming, and achieve the effects of improving heat sealing performance, broadening application fields, and good tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

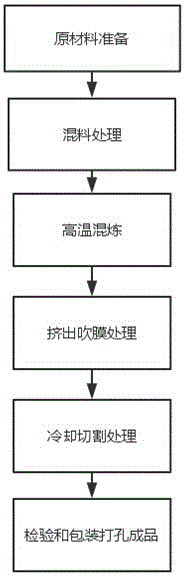

[0021] Such as figure 1 As shown, the production process of a high-toughness and high-impact-strength heat-shrinkable film packaging bag of this embodiment is characterized in that it comprises the following process steps:

[0022] 1) Raw material preparation: The raw materials for the heat shrinkable film include the following components (parts by weight): 85 parts of LDPE low-density polyethylene, 65 parts of LLDPE linear low-density polyethylene, 3 parts of magnesium stearate, 3 parts of pentaerythritol, ethylene - 55 parts of octene copolymer, 2 parts of calcium stearate, 3 parts of sorbitol, 2 parts of barium stearate, 2 parts of polyglycerol monostearate, 2 parts of glycerol, wherein the LDPE low density poly Ethylene has a melt index of 0.3g / 10min and a density of 0.93 g / cm 3 low-density polyethylene, wherein the LLDPE linear low-density polyethylene has a melt index of 0.45g / 10min and a density of 0.91 g / cm 3 linear low density polyethylene;

[0023] (2) Mixing trea...

Embodiment 2

[0028] Embodiment 2: The rest are the same as in Embodiment 1, except that in the step (1), the raw materials for the production of the heat shrinkable film include the following components (parts by weight): 80 parts of LDPE low-density polyethylene, LLDPE linear 60 parts of low-density polyethylene, 2 parts of magnesium stearate, 2 parts of pentaerythritol, 50 parts of ethylene-octene copolymer, 1 part of calcium stearate, 2 parts of sorbitol, 1 part of barium stearate, polyglycerol monohard 1 part of fatty acid ester, 1 part of glycerol; the LDPE low-density polyethylene described in the step (1) has a melt index of 0.35g / 10min; the LLDPE linear low-density polyethylene described in the step (1) The melt index is 0.5g / 10min and the density is 0.92g / cm 3 linear low-density polyethylene; the extrusion temperature of the film blowing machine in the step (4) is 210°C; the material is air-cooled to 45°C in the step (5), and the transverse stretch ratio is 6, and the longitudina...

Embodiment 3

[0029] Embodiment 3: The rest are the same as in Embodiment 1, except that in the step (1), the raw materials for the production of the heat shrinkable film include the following components (parts by weight): 82 parts of LDPE low-density polyethylene, LLDPE linear 63 parts of low-density polyethylene, 2 parts of magnesium stearate, 3 parts of pentaerythritol, 50-55 parts of ethylene-octene copolymer, 2 parts of calcium stearate, 2 parts of sorbitol, 1 part of barium stearate, polyglycerin 2 parts of monostearate, 1 part of glycerol; the LDPE low-density polyethylene described in the step (1) has a melt index of 0.4g / 10min; the LLDPE linear low-density polyethylene described in the step (1) Polyethylene has a melt index of 0.55g / 10min and a density of 0.93g / cm 3 linear low-density polyethylene; the extrusion temperature of the film blowing machine in the step (4) is 220°C; the material is air-cooled to 50°C in the step (5), and the transverse stretch ratio is 7, and the longit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com