Ionomer, method for producing the same and molded article of the same

A technology of ion cross-linking and polymers, which is applied in the field of ion cross-linking polymers, can solve problems such as preparation troubles, and achieve excellent scratch resistance, good rubber elasticity, good mechanical properties and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

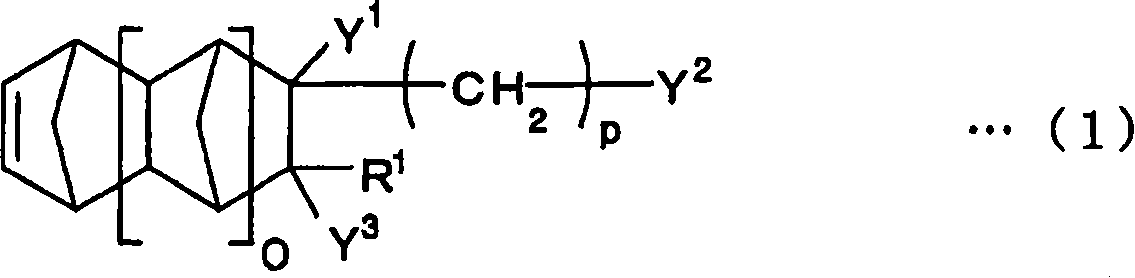

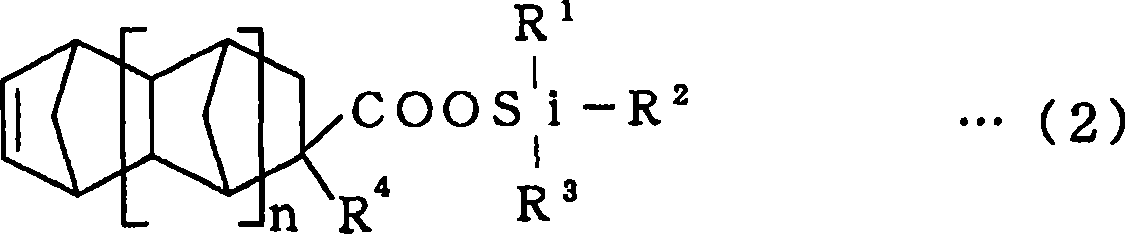

[0086] The second scheme of the preparation method of the ionomer of the present invention is to implement dynamic heat treatment to the olefinic random copolymer and the metal compound, wherein the olefinic random copolymer is made of ethylene, and the number of carbon atoms is 3 to 10. The α-olefin and the functional cyclic compound represented by the following general formula (2) are obtained by copolymerization,

[0087] [chemical 4]

[0088]

[0089] (In general formula (2), n is 0 or 1, R 1 , R 2 , R 3 and R 4 each independently represents a hydrogen atom, a halogen atom or a monovalent organic group).

[0090] [Olefin-based random copolymer]

[0091] The olefin-based random copolymer used in the production method of the ionomer of this embodiment uses ethylene as a monomer. The proportion of ethylene used is preferably 35 to 94.99 mol%, more preferably 40 to 89.99 mol%, particularly preferably 45 to 84.99 mol%, of the total monomers. When the usage ratio of et...

Embodiment 1

[0196] 100 parts by mass of specific functional group-containing copolymer (A-1), 1 part by mass of metal compound particles (B-1), 4.5 parts by mass of activator (D-1) and 0.2 parts by mass of anti-aging agent were added to the heating to 10L double-arm pressure kneader (manufactured by Moriyama Corporation) at 230°C, kneading for 20 minutes at 40rpm (shear rate 200s -1 ). Then, the resulting molten lump-shaped kneaded product was pelletized by using a Fidelder (manufactured by Moriyama Corporation) set at 180° C. and 40 rpm to obtain ionomer pellets. The pellets of the obtained ionomer were prepared under the conditions of a mold temperature of 180° C., a pressurized heating time of 10 minutes, and a pressurized cooling time of 5 minutes by an electric heating pressurization molding machine (manufactured by Kansai Roull Co., Ltd.). Press molding was performed to obtain a molded sheet of 12 cm x 12 cm x 0.2 cm.

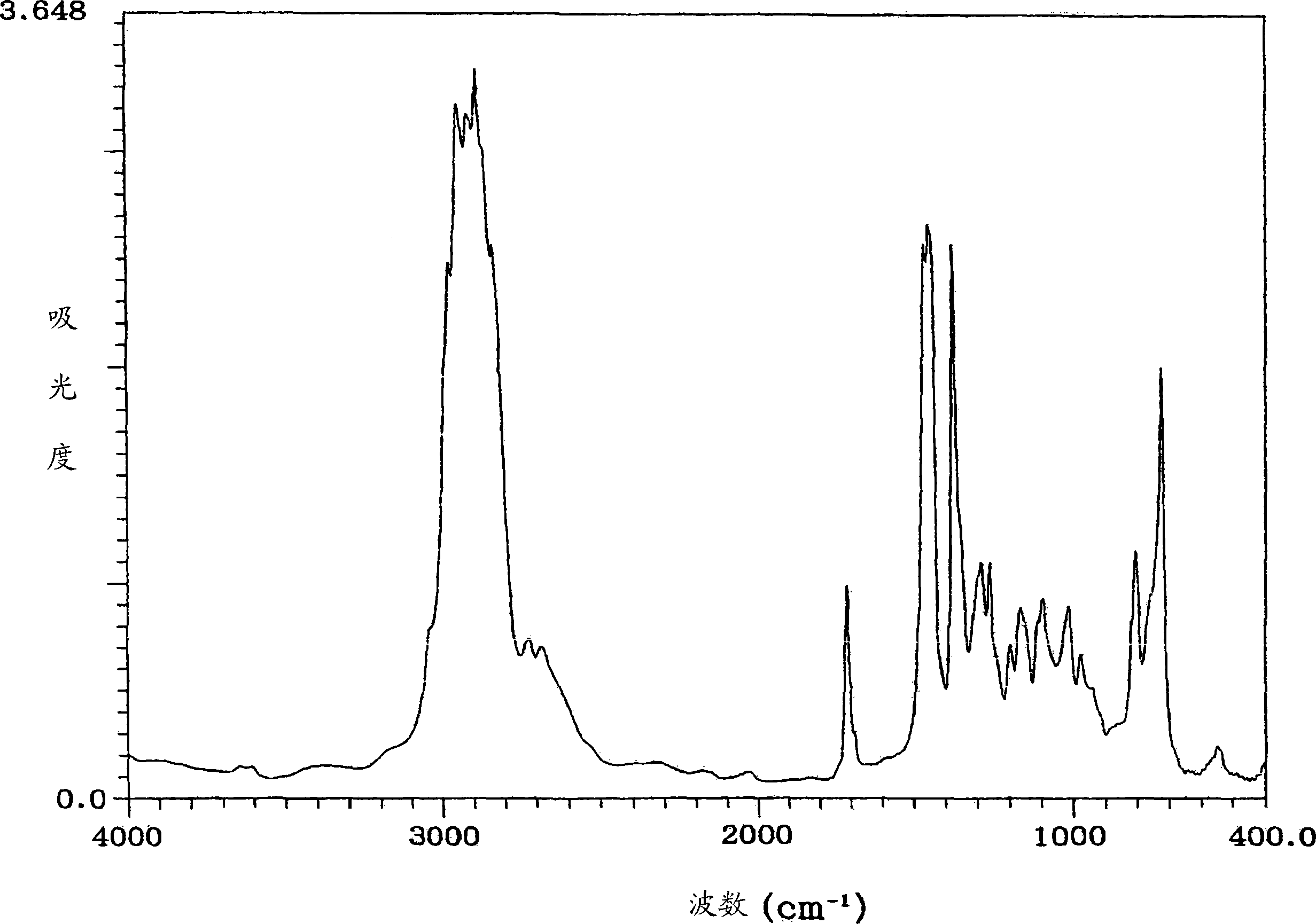

[0197] Using the Fourier transform infrared spectrophotometer...

Embodiment 2~7 and comparative example 2

[0212] According to the mixing ratio shown in Table 1 below, each component was put into a 10 L double-arm pressure kneader (manufactured by Moriyama Co., Ltd.) heated to 230° C., and kneaded at 40 rpm for 20 minutes. Then, the obtained melted block kneaded material was made into pellets by a Fidelder (manufactured by Moriyama Corporation) set at 180° C. and 40 rpm to obtain an ionomer or ionomer composition pellets. In the same manner as in Example 1, the pellets of the obtained granulated ionomer or ionomer composition were formed into molded tablets by press molding, and evaluated. The results are shown in Table 1.

[0213] Example

comparative example

1

2

3

4

5

6

7

1

2

become

Minute

of

mix

combine

Compare

example

︵

quality

quantity

share

︶

Specific functional group-containing copolymer (A-1)

Specific functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com