Dispersing method of PTFE superfine powder and application of dispersion liquid thereof in non-stick coating

A technology of non-stick coating and ultrafine powder, which is applied in the direction of coating, can solve the problems of adding, etc., and achieve the effect of convenient construction, enhanced flexibility and improved impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1: (1) Add 5.0g PTFE superfine powder, 0.5g dispersant, 6.5g mixed solvent, 28.0g high polyester modified silicone resin to the clean solvent successively, the weight of PTFE superfine powder accounts for the resin and 15.2% of the total weight of the PTFE ultrafine powder; (2) carry out dispersion stirring with a propeller, the stirring speed is 250rmp, the dispersion time is 3h, and the dispersion temperature is 25° C. to obtain the dispersion liquid of the PTFE ultrafine powder.

[0046] Step 2: Measure and weigh 28.0g high polyester modified silicone resin, 7.5g mixed solvent, 0.5g dispersant, 0.9g leveling agent, 0.3g defoamer, 0.1g non-stick additive, 10g talc powder, Add 1.7g of fumed silica R972 and 10.0g of white pigment into the grinding tank, grind and disperse for 2-6 hours, and filter to obtain the masterbatch of non-stick coating;

[0047] Step 3: Add the masterbatch of the non-stick coating obtained in step 2 to the dispersion of PTFE ultrafine powde...

Embodiment 2-10

[0050] Adopt the same method as in Example 1, prepare dispersion liquid and non-stick coating masterbatch according to the weight of table 1 and table 2, finally obtain non-stick coating:

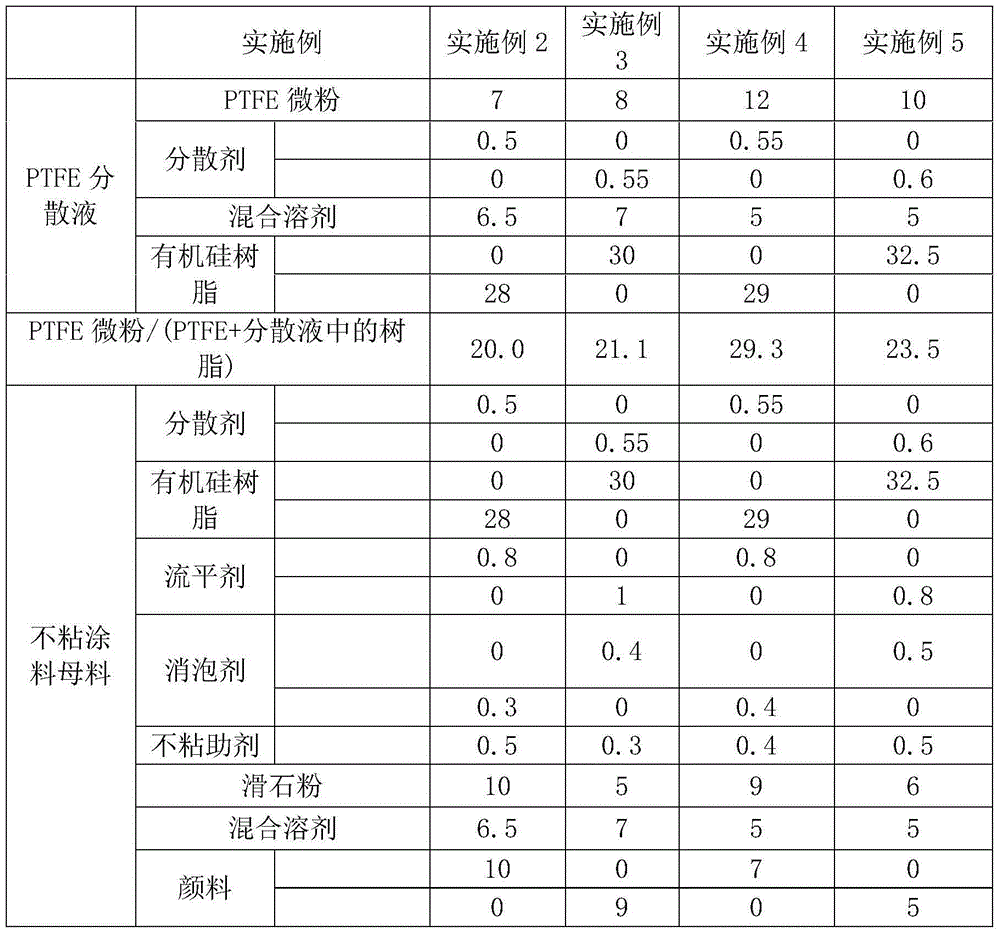

[0051] The composition of table 1 embodiment 2-5

[0052]

[0053]

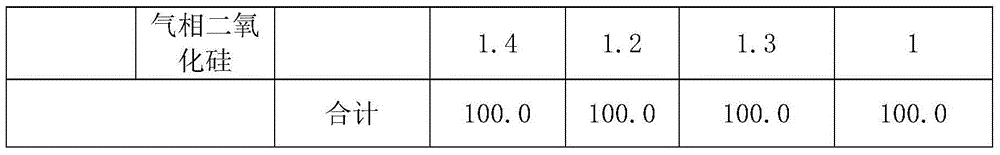

[0054] The composition of table 2 embodiment 6-10

[0055]

[0056] The dispersion liquid prepared by the embodiment of the present invention 1-10 is evaluated by the fineness method for dispersion uniformity; the non-stick coating prepared by the embodiment of the present invention 1-10 is evaluated for storage stability, and the non-stick coating is prepared according to the prescribed method. After making test samples (curing temperature 220°C, curing time 15min), performance evaluations such as adhesion, impact resistance, hardness and thermal hardness, chemical resistance, salt spray resistance, contact angle and non-stickiness were carried out; The coating is applied to the rubber product molding mold, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com