Preparation method of amorphous titanium dioxide for lithium titanate

A titanium dioxide, amorphous technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of not meeting the requirements, and achieve the effect of easy implementation, low production cost and good dispersion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

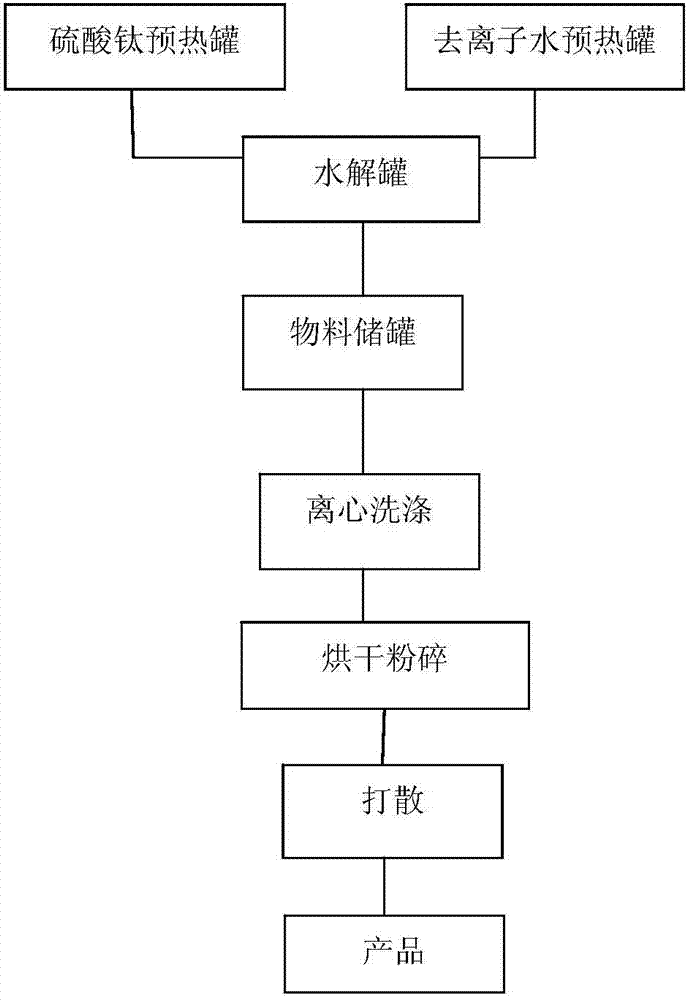

Method used

Image

Examples

Embodiment 1

[0033] Take 1000ml of titanium sulfate solution with a concentration of 60g / L, heat it to 50°C titanium sulfate, and evenly add it to 2000ml of deionized water heated to 60°C, and control the stirring speed at 10 rpm. After stirring for 20 minutes, put the material into the hydrolysis tank, 120ml of ammonium carbonate solution with a mass concentration of 5% has been added in advance in the hydrolysis tank, put the metatitanic acid into the material storage tank after hydrolysis together and let it stand for 12 hours, then put the material liquid Put it into the centrifuge where the filter cloth has been laid, and slowly turn on the centrifuge at a speed of 5 rpm. After the material is dried, add deionized water three times the volume of the material in three times, add in three times for washing, and remove To remove impurity ions, the temperature of deionized water is controlled at 40°C. Put the washed material into a stainless steel tray, add TMP with a mass concentration o...

Embodiment 2

[0035] Take 1000ml of titanium sulfate solution with a concentration of 60g / L, heat it to 60°C titanium sulfate, and evenly add it to 2000ml of deionized water heated to 70°C, and control the stirring speed at 20 rpm. After stirring for 30 minutes, put the material into the hydrolysis tank, 120ml of ammonium carbonate solution with a mass concentration of 8% has been added in advance in the hydrolysis tank, put the metatitanic acid into the material storage tank after hydrolysis and let it stand for 15 hours, then put the material liquid Put it into the centrifuge where the filter cloth has been laid, and slowly turn on the centrifuge at a speed of 8 rpm. After the material is dried, add deionized water three times the volume of the material in three times, add washing in three times, remove To remove impurity ions, the temperature of deionized water is controlled at 40°C. Put the washed material into a stainless steel tray, add TMP with a mass concentration of 3% in an amount...

Embodiment 3

[0037] Take 1000ml of titanium sulfate solution with a concentration of 60g / L, heat it to 70°C titanium sulfate, and evenly add it to 2000ml of deionized water heated to 80°C, and control the stirring speed at 20 rpm. After stirring for 30 minutes, put the material into the hydrolysis tank, 120ml of ammonium carbonate solution with a mass concentration of 7% has been added in advance in the hydrolysis tank, put the metatitanic acid into the material storage tank after hydrolysis and let it stand for 12 hours, then put the material liquid Put it into the centrifuge where the filter cloth has been laid, and slowly turn on the centrifuge at a speed of 8 rpm. After the material is dried, add deionized water three times the volume of the material in three times, add washing in three times, remove To remove impurity ions, the temperature of deionized water is controlled at 40°C. Put the washed material into a stainless steel tray, add TMP with a mass concentration of 3% in an amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com