Preparation method of carbon nanotube-polyvinyl alcohol gel microspheres

A polyvinyl alcohol gel and carbon nanotube technology, which is applied in the direction of microsphere preparation, gel preparation, microcapsule preparation, etc., can solve the problems of easy secondary agglomeration and poor dispersion of carbon nanotubes, and achieve short preparation process and Maintain structural integrity and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

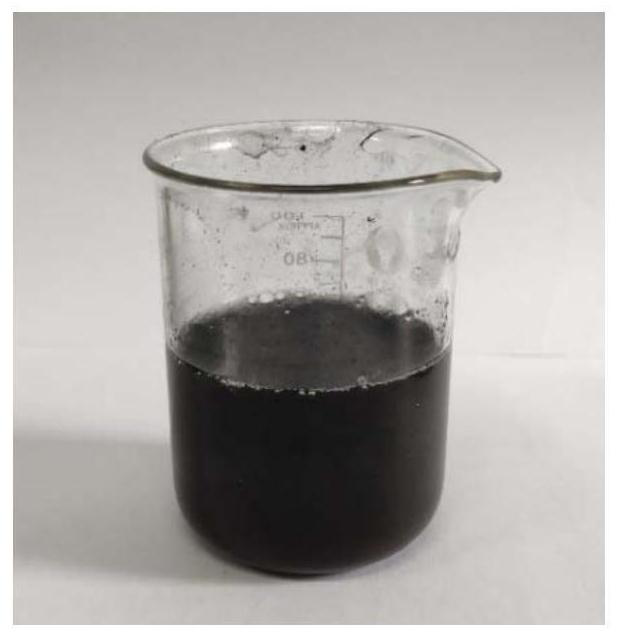

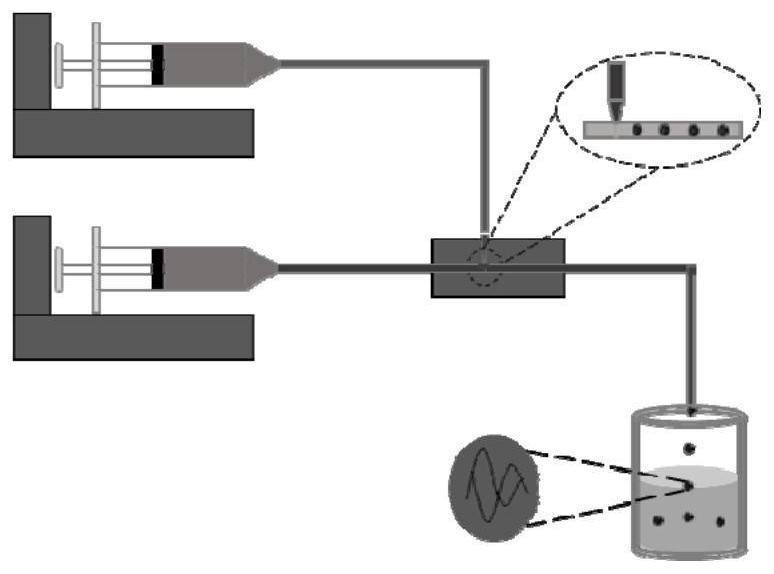

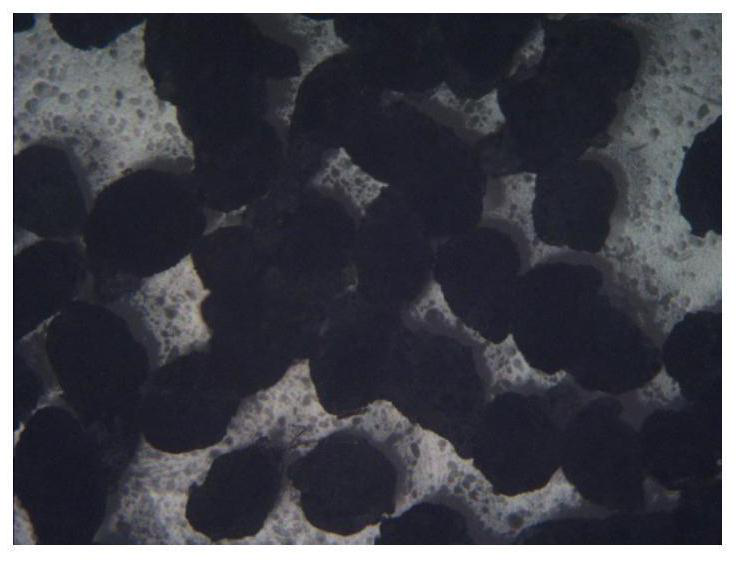

[0030] (1) Add 0.5 g of PVA to 49.5 g of water, raise the temperature to 90° C. and keep it warm for 1.5 h, and wait for it to dissolve to form a polyvinyl alcohol aqueous solution with a concentration of 1.0 wt.%. After cooling, add 0.5g of carbon nanotubes for ultrasonic dispersion to form dispersion 1; add 3g of PVA to 47g of water, heat up to 90°C for 2 hours, and wait for it to dissolve to form dispersion 2. The concentration of dispersion 1 and dispersion 2 The ratio is 1:6; the above two dispersion liquids are mixed, and magnetically stirred for 30 min to form a dispersed phase liquid of carbon nanotubes.

[0031] (2) Add 1.5mL of surfactant Sapn-80 into 48.5mL of liquid paraffin, ultrasonically oscillate to completely dissolve Span-80 in the liquid, and obtain a continuous phase liquid with a volume fraction of surfactant of 3%.

[0032] (3) Add 1.5g of borax to a mixture of 50mL of isoamyl alcohol and 25mL of triethanolamine, magnetically stir and slowly heat to 60°C ...

Embodiment 2

[0035] (1) Add 0.25g of PVA to 49.75g of water, raise the temperature to 80°C and keep it warm for 1h, and wait for it to dissolve to form an aqueous solution of polyvinyl alcohol with a concentration of 0.5wt.%. After cooling, add 0.4g of carbon nanotubes for ultrasonic dispersion to form dispersion 1; add 3.5g of PVA to 71.5g of water, raise the temperature to 90°C for 2 hours, and wait for it to dissolve to form dispersion 2. The difference between dispersion 1 and dispersion 2 The concentration ratio is 1:9.3; the above two dispersion liquids are mixed and magnetically stirred for 30 min to form a dispersed phase liquid of carbon nanotubes.

[0036] (2) Add 2mL of surfactant Sapn-80 into 48mL of silicone oil and oscillate ultrasonically to completely dissolve Span-80 in the liquid to obtain a continuous phase liquid with a volume fraction of 4% surfactant.

[0037] (3) Add 1.5g of borax to a mixture of 30mL of hexanol and 15mL of diethanolamine, magnetically stir and slowl...

Embodiment 3

[0040] (1) Add 1.0 g of PVA to 49 g of water, raise the temperature to 90° C. for 2 hours, and wait for it to dissolve to form an aqueous solution of polyvinyl alcohol with a concentration of 2.0 wt.%. After cooling, add 0.5g of carbon nanotubes for ultrasonic dispersion to form dispersion 1; add 6g of PVA to 44g of water, heat up to 90°C for 2 hours, and wait for it to dissolve to form dispersion 2. The concentration of dispersion 1 and dispersion 2 The ratio is 1:6; the above two dispersion liquids are mixed, and magnetically stirred for 30 min to form a dispersed phase liquid of carbon nanotubes.

[0041] (2) Add 2.5mL of surfactant Sapn-80 into 47.5mL of liquid paraffin, ultrasonically oscillate to completely dissolve Span-80 in the liquid, and obtain a continuous phase liquid with a volume fraction of 5% surfactant.

[0042] (3) Add 1.5g of borax to a mixture of 20mL of isooctyl alcohol and 10mL of triethanolamine, magnetically stir and slowly heat to 60°C to dissolve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com