Preparation method of graphene material and application of graphene material in preparation of lithium ion battery

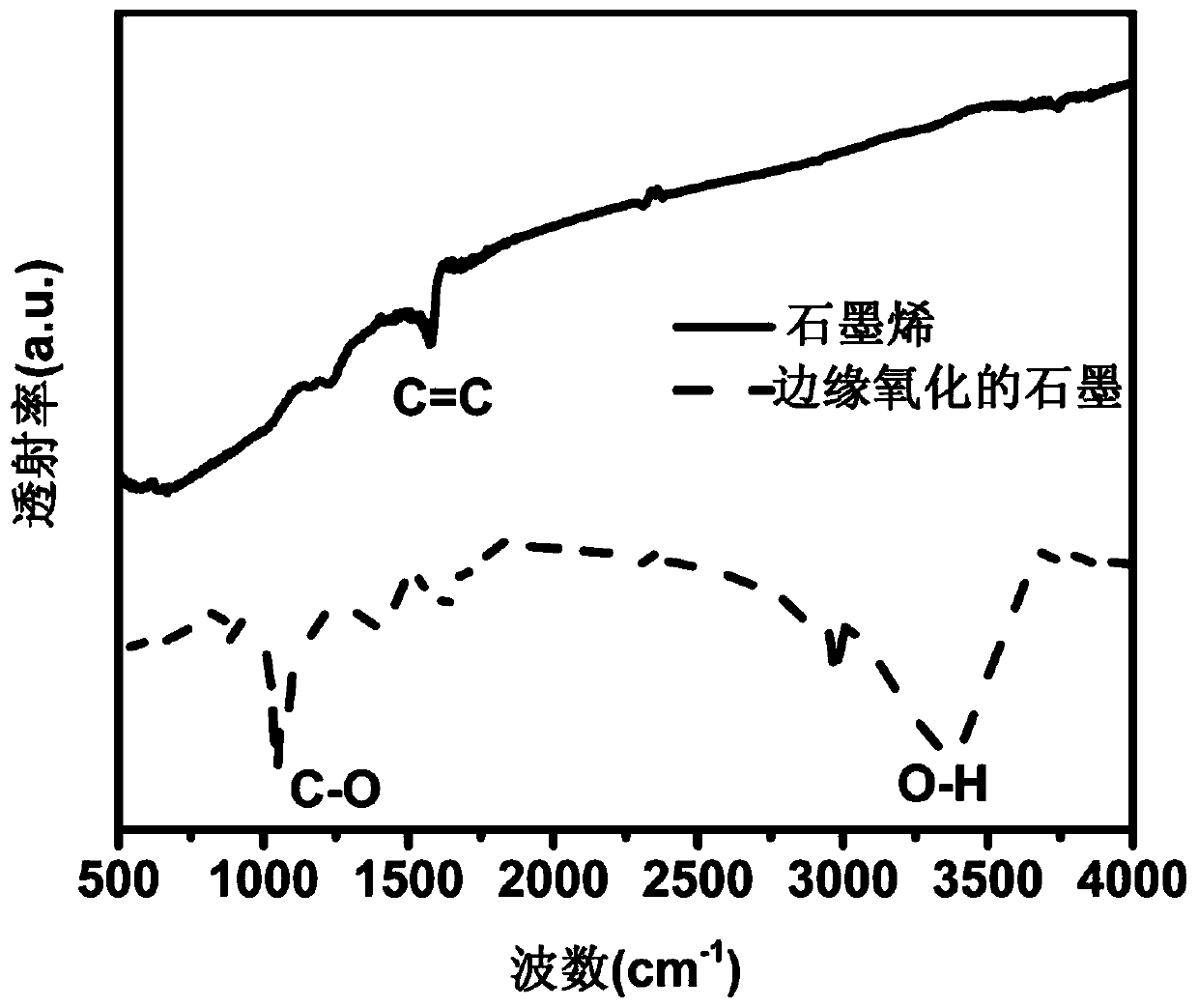

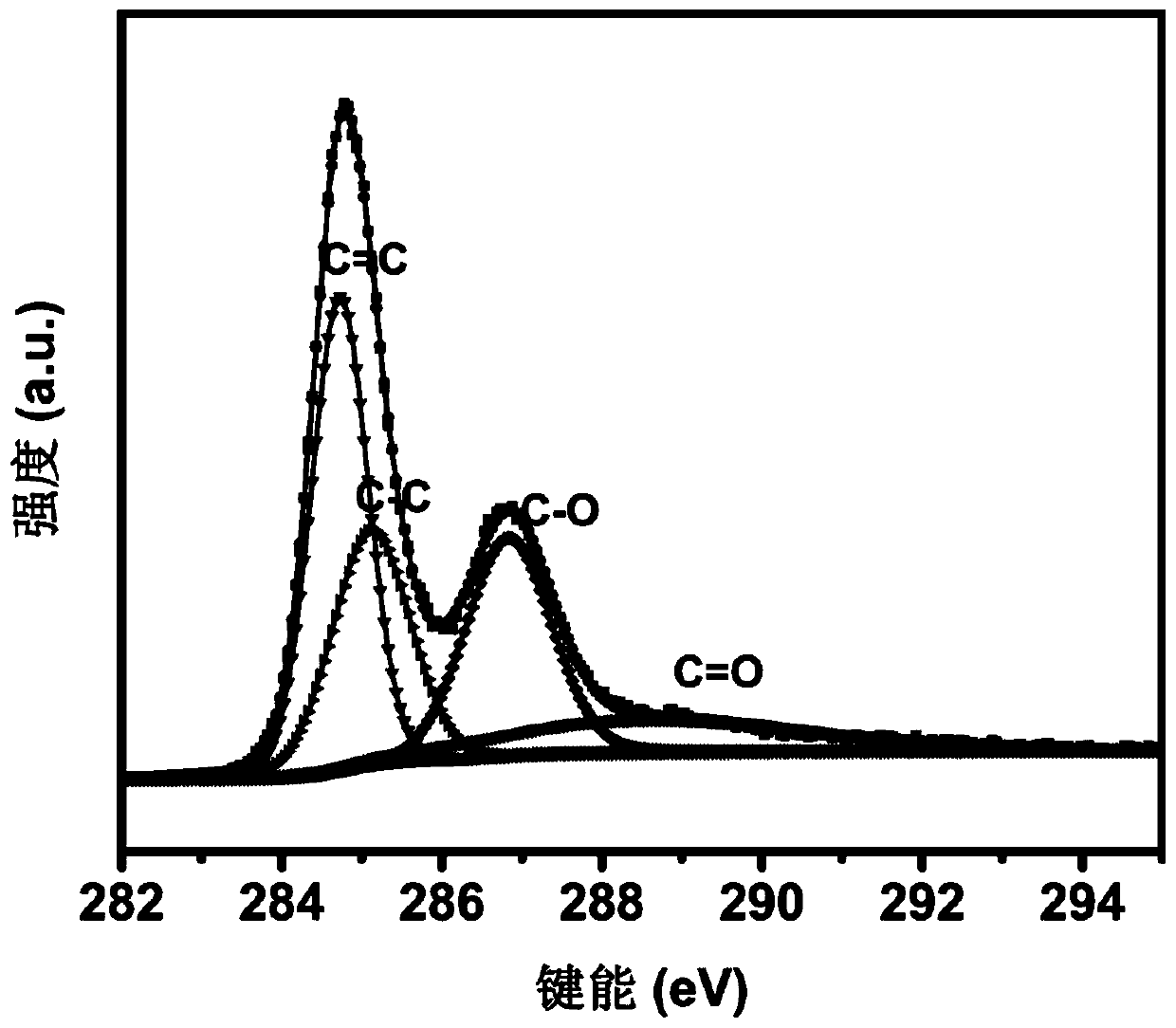

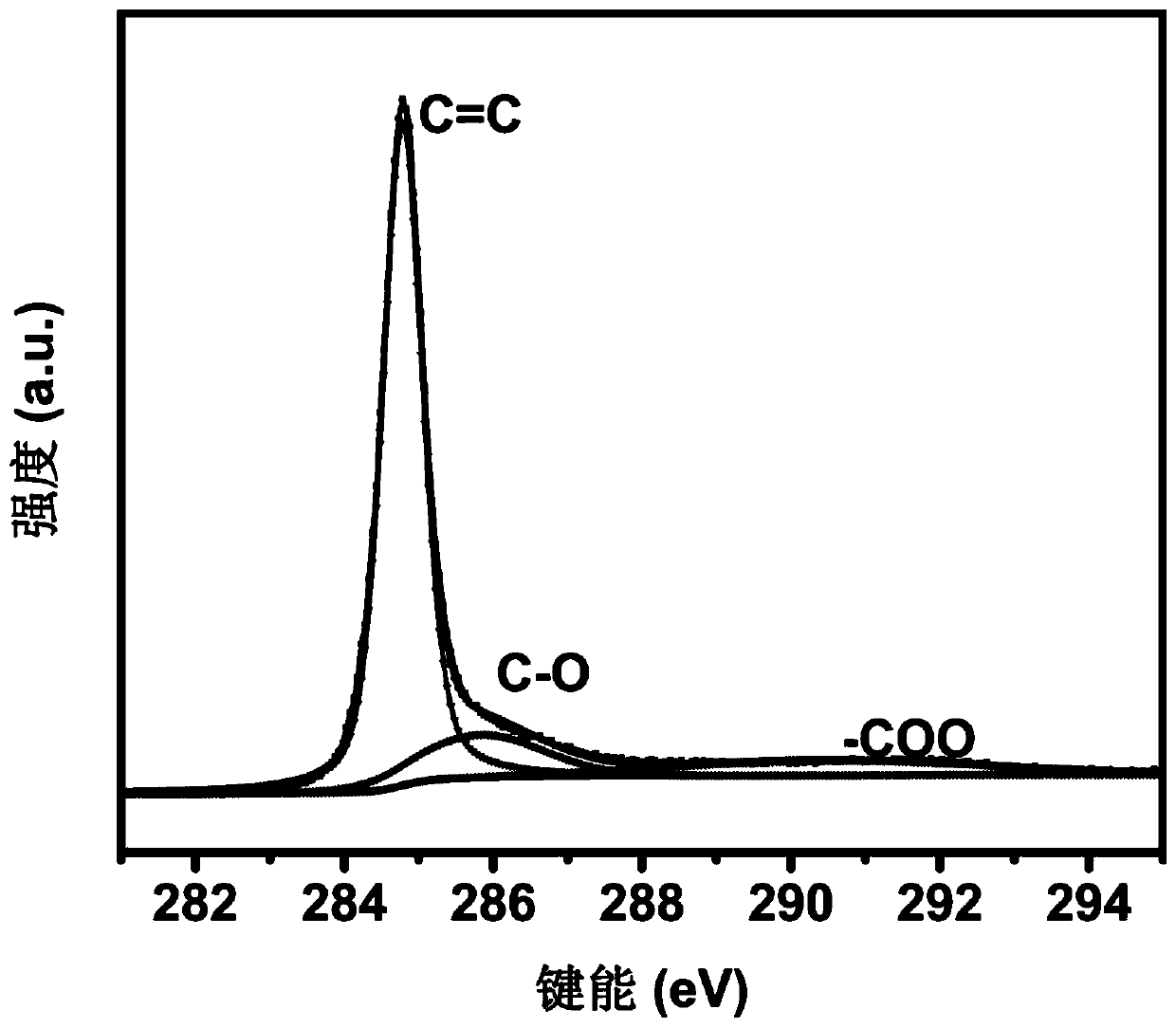

A graphene and graphite powder technology, applied in graphene, battery electrodes, secondary batteries, etc., can solve the problems of long reaction time and reaction temperature, potential safety hazards, small risks, etc., and achieve short time consumption, low pollution, and high performance outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of graphene material, the steps are as follows:

[0049] 1) Preparation of graphene oxide precursor material

[0050] Take 50ml of concentrated sulfuric acid with a mass fraction of 98%, and place it in a 250ml three-necked flask; place the three-necked flask in a water bath to maintain a constant temperature of 25°C; use an electric mechanical stirrer to continuously stir the concentrated sulfuric acid in the three-necked flask; take high-purity flake graphite Add 10g into the concentrated sulfuric acid, after stirring continuously for 30min, take 15g of potassium ferrate, add it into the concentrated sulfuric acid slowly, and finish adding in about 30min; generate highly active oxygen through the plasma generator and pass it into the mixed solution at a volume flow rate of 100ml / min Keep constant temperature, keep stirring for 1h; slowly add 15ml of pure water, keep stirring for 1h, then slowly add 8ml of hydrogen peroxide with a volume fraction o...

Embodiment 2

[0061] A preparation method of graphene material, the steps are as follows:

[0062] 1) Preparation of graphene oxide precursor material

[0063] Take 50ml of concentrated sulfuric acid with a mass fraction of 98%, and place it in a 250ml three-necked flask; place the three-necked flask in a water bath to maintain a constant temperature of 25°C; use an electric mechanical stirrer to continuously stir the concentrated sulfuric acid in the three-necked flask; take high-purity flake graphite Add 2.5g into the concentrated sulfuric acid, after stirring continuously for 30min, take 5g of potassium ferrate, add it into the concentrated sulfuric acid slowly, and finish adding in about 30min; generate high active oxygen through the plasma generator and pass it into the mixture at a volume flow rate of 150ml / min solution; keep constant temperature, keep stirring for 1 hour; slowly add 10ml of pure water, keep stirring for 1 hour, then slowly add 20ml of hydrogen peroxide with a volume ...

Embodiment 3

[0070] A preparation method of graphene material, the steps are as follows:

[0071] 1) Preparation of graphene oxide precursor material

[0072] Take 50ml of concentrated sulfuric acid with a mass fraction of 98%, and place it in a 250ml three-necked flask; place the three-necked flask in a water bath to maintain a constant temperature of 25°C; use an electric mechanical stirrer to continuously stir the concentrated sulfuric acid in the three-necked flask; take high-purity flake graphite Add 2.5g into concentrated sulfuric acid, and after stirring continuously for 30min, take 7.5g of potassium ferrate, slowly add it into concentrated sulfuric acid, and finish adding in about 30min; generate highly active oxygen through a plasma generator and pass it in at a volume flow rate of 200ml / min Mix solution; keep constant temperature, keep stirring for 1h; slowly add 25ml of pure water, keep stirring for 1h, then slowly add 8ml of hydrogen peroxide with a volume fraction of 30%, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com