Layered-modeling device and method using said device for manufacturing three-dimensional objects

一种层叠造型、三维形状的技术,应用在制造辅助装置、加工制造、制造工具等方向,能够解决烟气易充满腔室、加工精度降低、光束输出或聚光度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

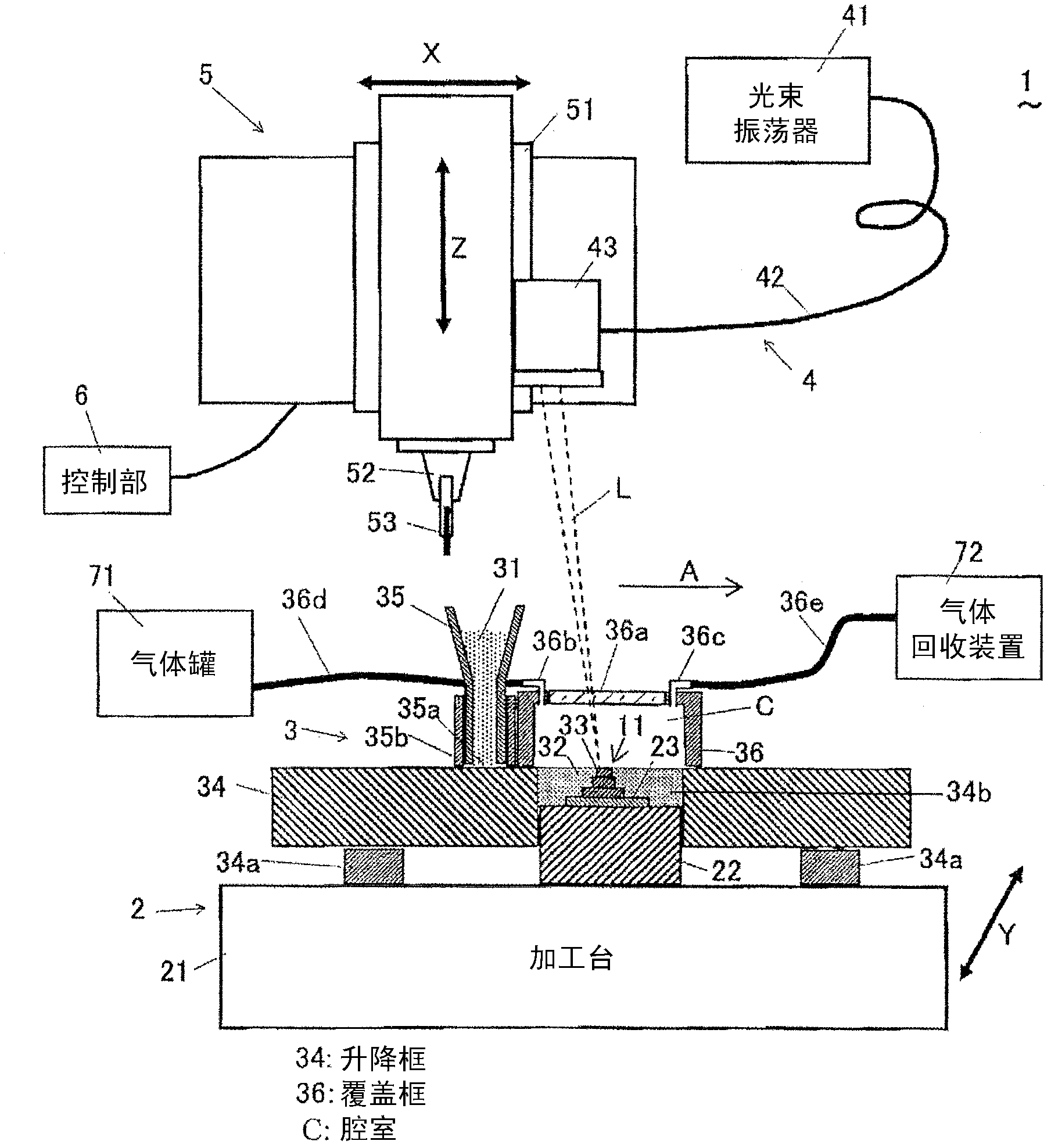

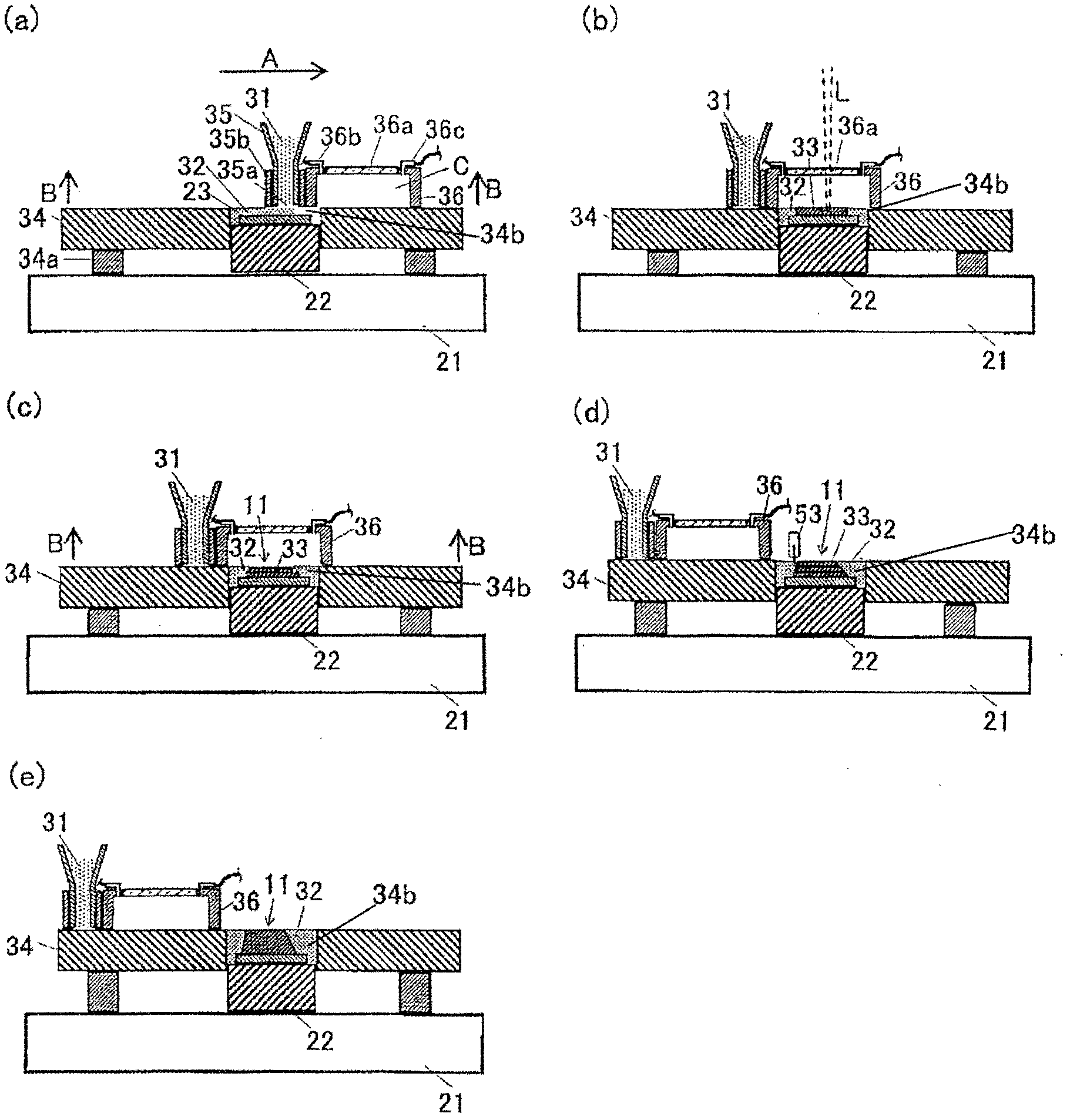

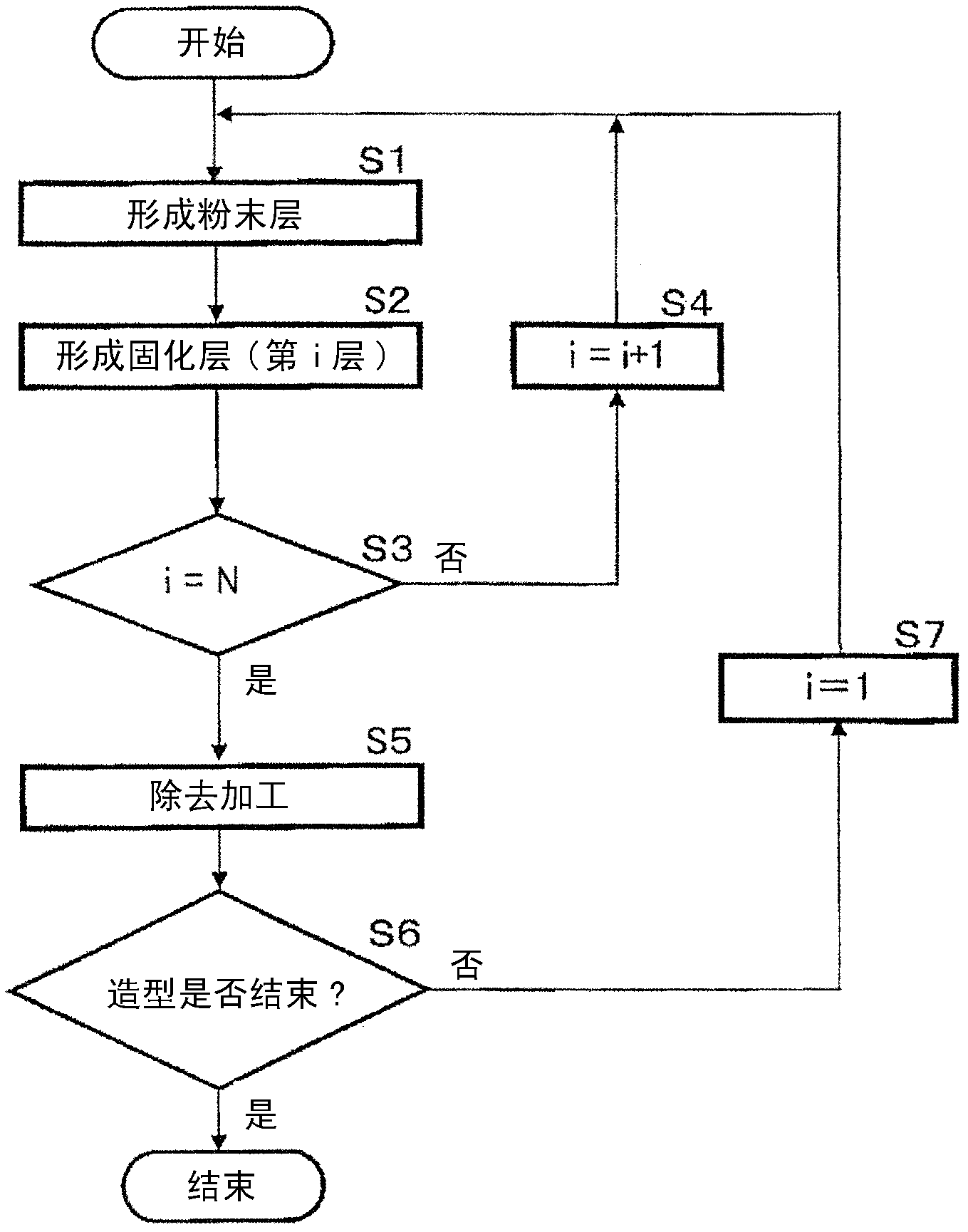

[0083] A method of manufacturing a three-dimensional modeled object according to an embodiment of the present invention will be described with reference to the drawings. figure 1 The structure of the lamination molding apparatus (hereinafter referred to as "this apparatus") used in this production method is shown. This device 1 includes: a molding unit 2 for molding a three-dimensional shaped object 11; a powder layer forming unit (powder layer forming mechanism) 3 for supplying material powder 31 to form a powder layer 32; and forming a powder layer 32 by irradiating a beam L. The beam irradiation unit 4 for the solidified layer 33 ; the cutting and removal unit 5 for cutting the periphery of the molded object 11 ; and the control unit 6 for controlling the operation of each unit. By irradiating the light beam L, the powder layer 32 is sintered or melt-solidified to form the solidified layer 33 . This apparatus 1 further includes: a gas tank (shielding gas supply mechanism) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com