Powder feeder for material deposition systems

a technology of material deposition system and feeder, which is applied in the direction of packaging, manufacturing environment conditioning, liquid/fluent solid measurement, etc., can solve the problems of very inaccurate process, limited choice of materials, and the potential for making very complex parts of solid, hollow or lattice construction, etc., to achieve accurate dimensions, enhance mechanical properties of parts, and eliminate substrate warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] 1. Forming Structures Directly from a CAD Solid Model

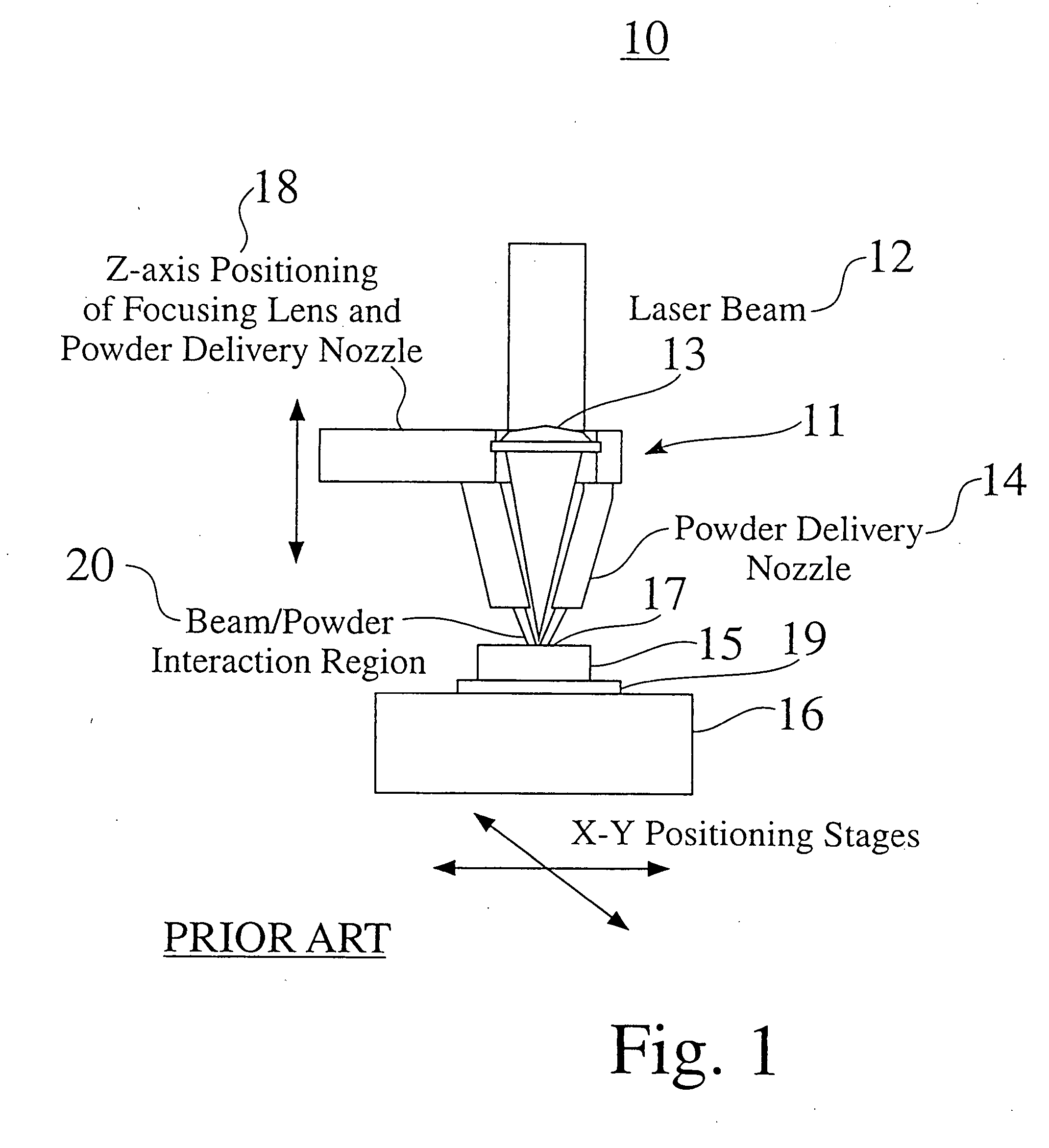

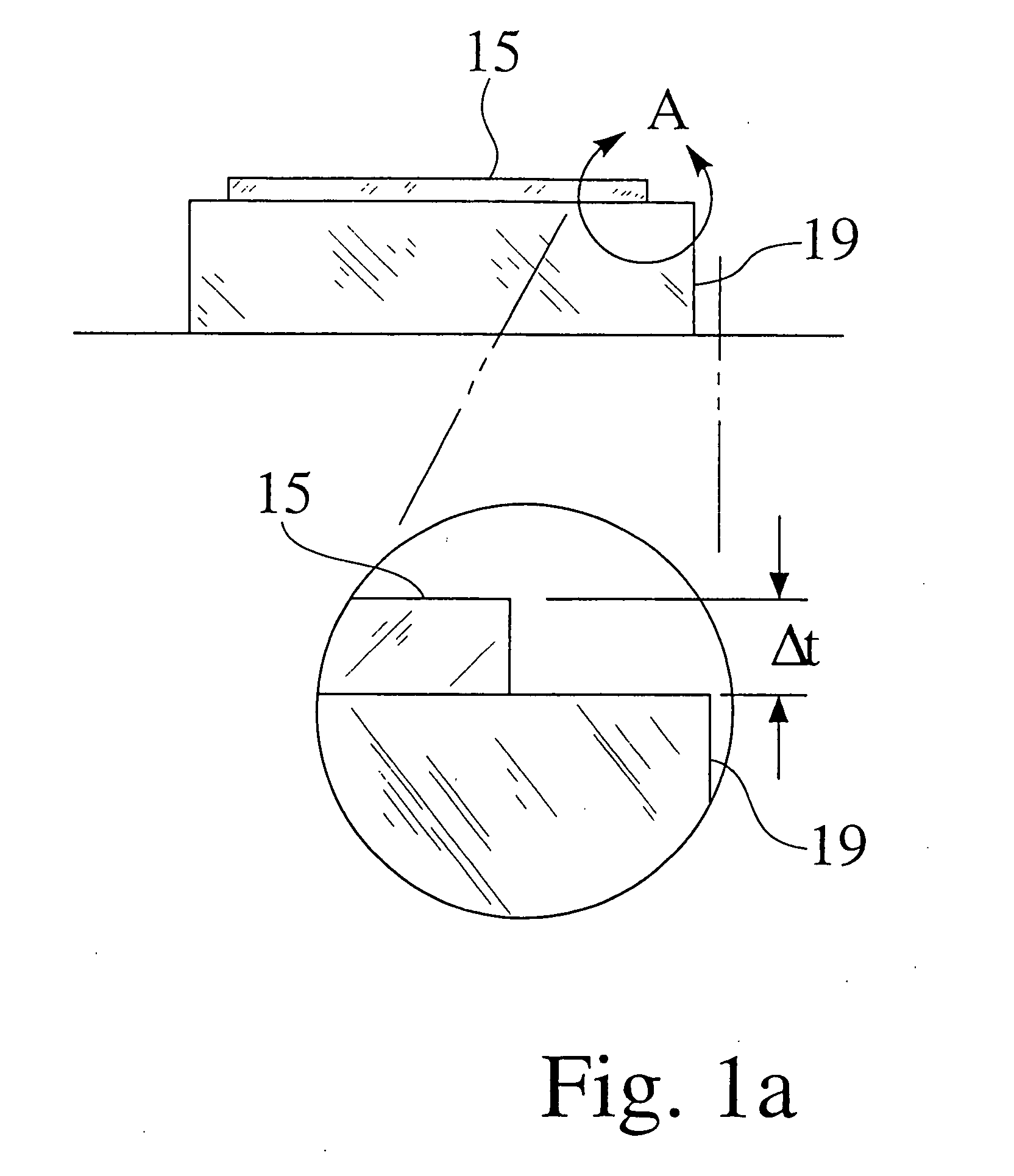

[0097] The present invention comprises apparatus and methods for fabricating metallic hardware with exceptional material properties and good dimensional repeatability. The term “net shape” refers to an article fabricated to the approximate desired size and features, solid or latticed, by a process which requires little or no machining. The prior art in this technology has focused on methods to enable the deposition process. However, little work has been done on how to best control the process to achieve a desired outcome in a solid structure.

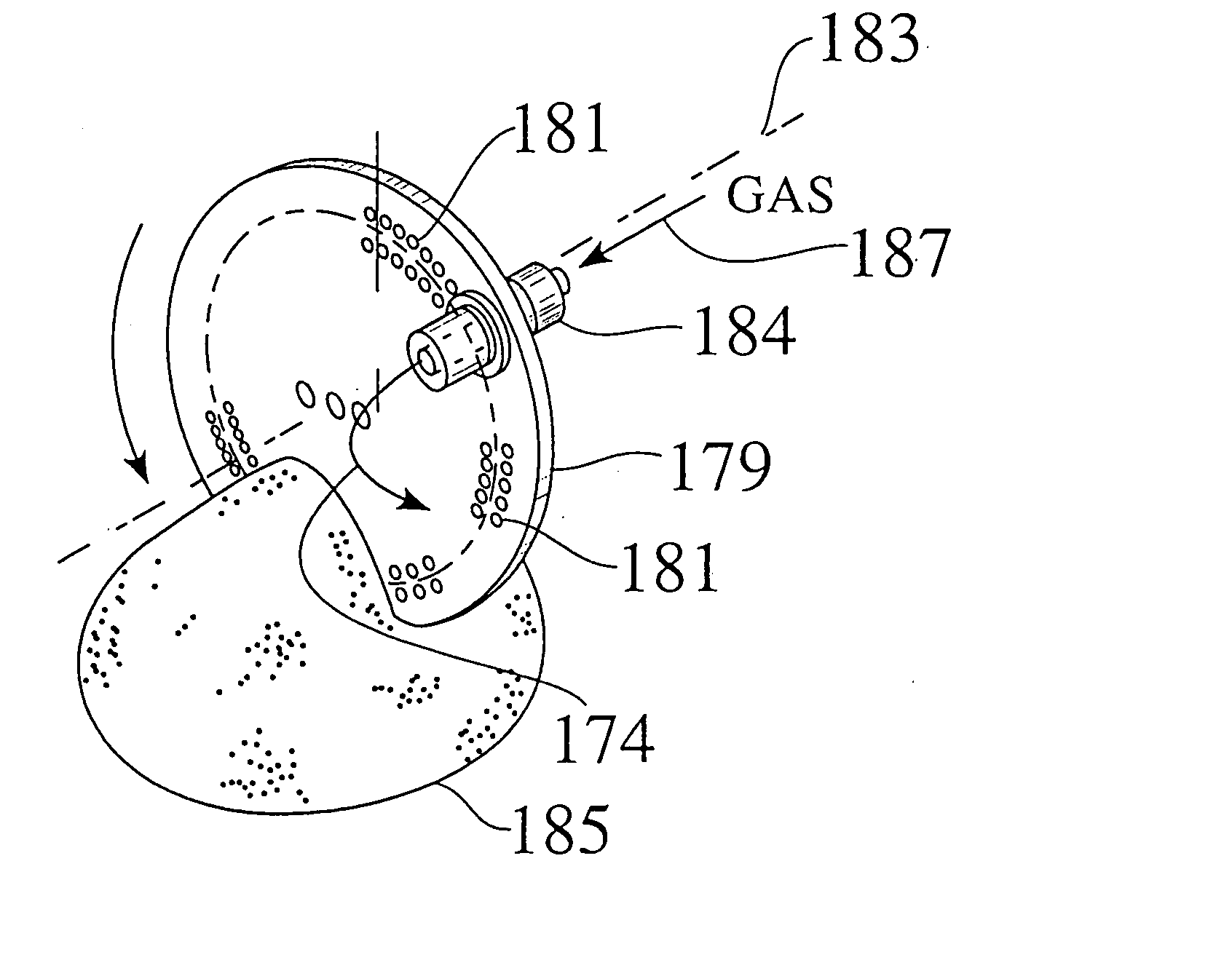

[0098] The present invention uses the laser-based process to provide users with the ability to create a net shape or near-net shape, fully dense, metallic object directly from a computer aided design (CAD) solid model. The shapes are created a layer at time. In this Specification and in the claims that follow, the invention is referred to as a directed material deposition (DMD) proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com