Personalizedly customized reticular porous carbon and preparation method thereof

A technology of reticulated porous and porous carbon, which is applied in the preparation/purification of carbon, can solve the problems of difficult control of pore shape, distortion, and difficulty in preparing porous carbon with complex shapes, so as to achieve the internal micro-pore shape and reduce distortion. and shrinkage deformation, controllable effect of microscopic pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing a personalized mesh porous carbon of the present invention comprises the following steps:

[0042] 1) Use 3D design software to design the outline and internal pore structure of the digital model of the personalized porous scaffold. The arbitrarily complex shape, microscopic pore parameters, ordered pore structure and gradient pore structure of the network porous carbon are controlled, and the microscopic design dimensions of the digital model are as follows: the diameter of the inscribed circle on each face of the polyhedron forming the network porous digital model is 0.2 ~ 4mm , the diameter of the inscribed circle in the cross section of the polyhedral connecting rod is 0.2-3mm.

[0043] 2) Use the digital model in step 1) to manufacture a personalized and customized network porous carbon precursor; the manufacturing method of the porous carbon precursor includes mold method and additive manufacturing method, and the types of network porous car...

Embodiment 1

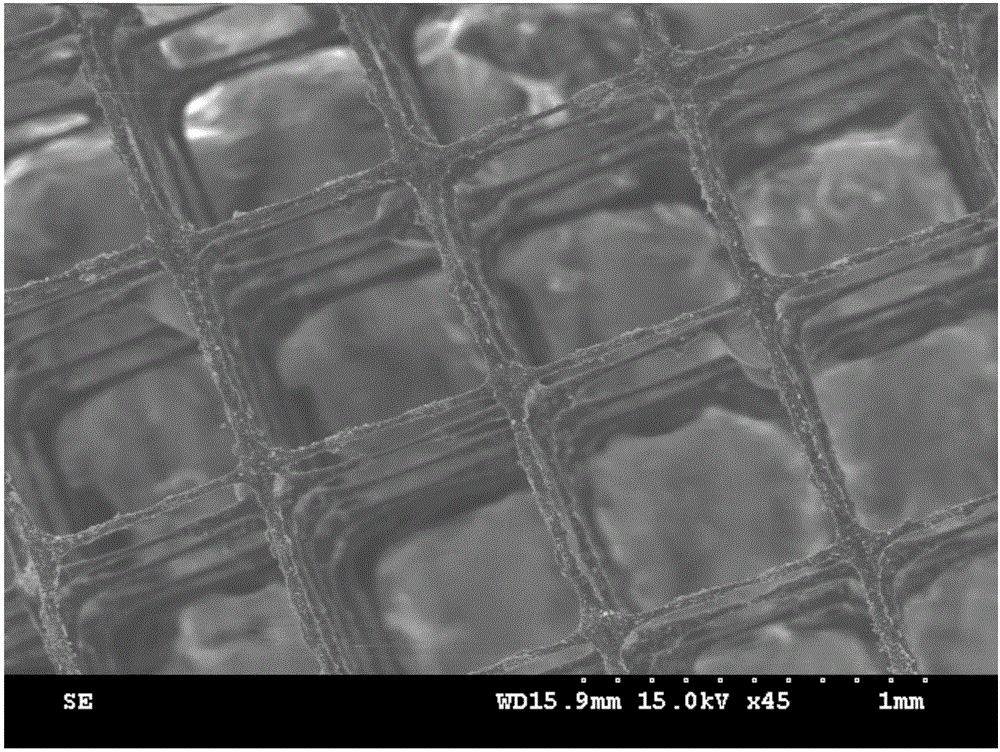

[0050] see Figure 1 to Figure 6 , the present invention is a kind of personalized mesh porous carbon and preparation method thereof, comprising the following steps:

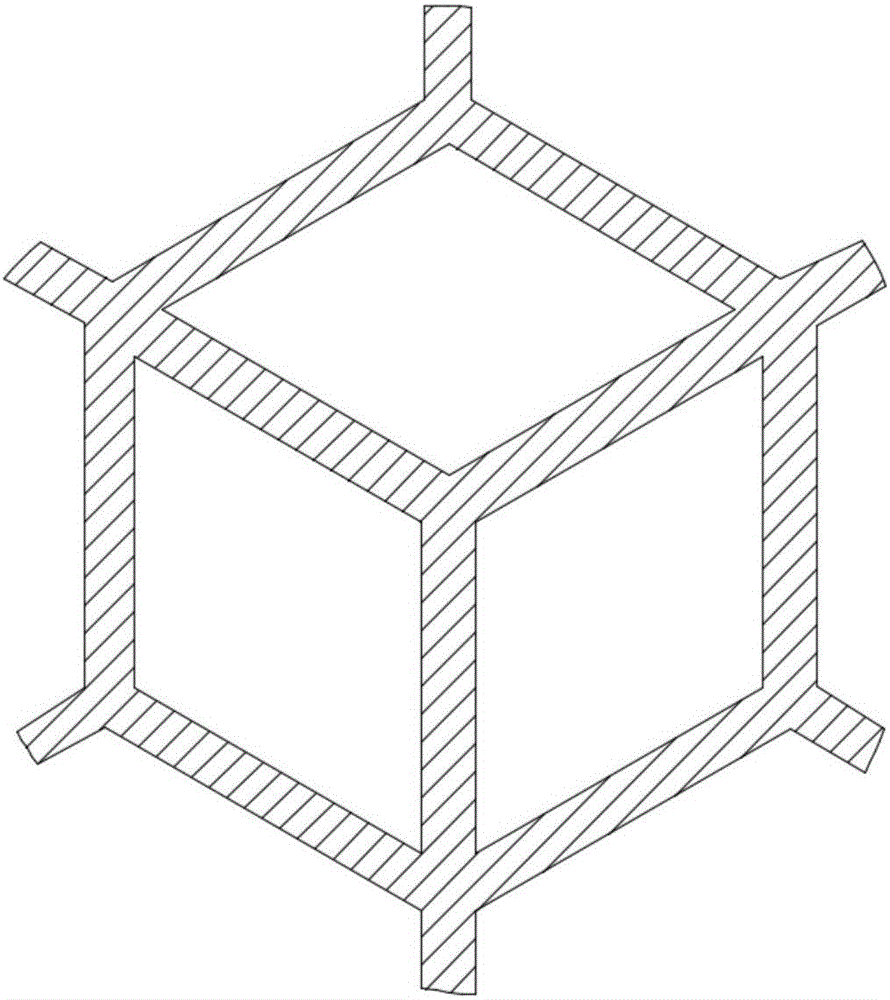

[0051] Step 1) Use 3D design software to design the outline and internal pore structure of the customized porous scaffold digital model. The microscopic pores inside the scaffold are composed of polyhedral units, and the diameter of the inscribed circle on each face of the polyhedron forming the network porous digital model is 0.2 ~4mm, the diameter of the inscribed circle in the cross section of the polyhedral connecting rod is 0.2~3mm, see figure 2 shown;

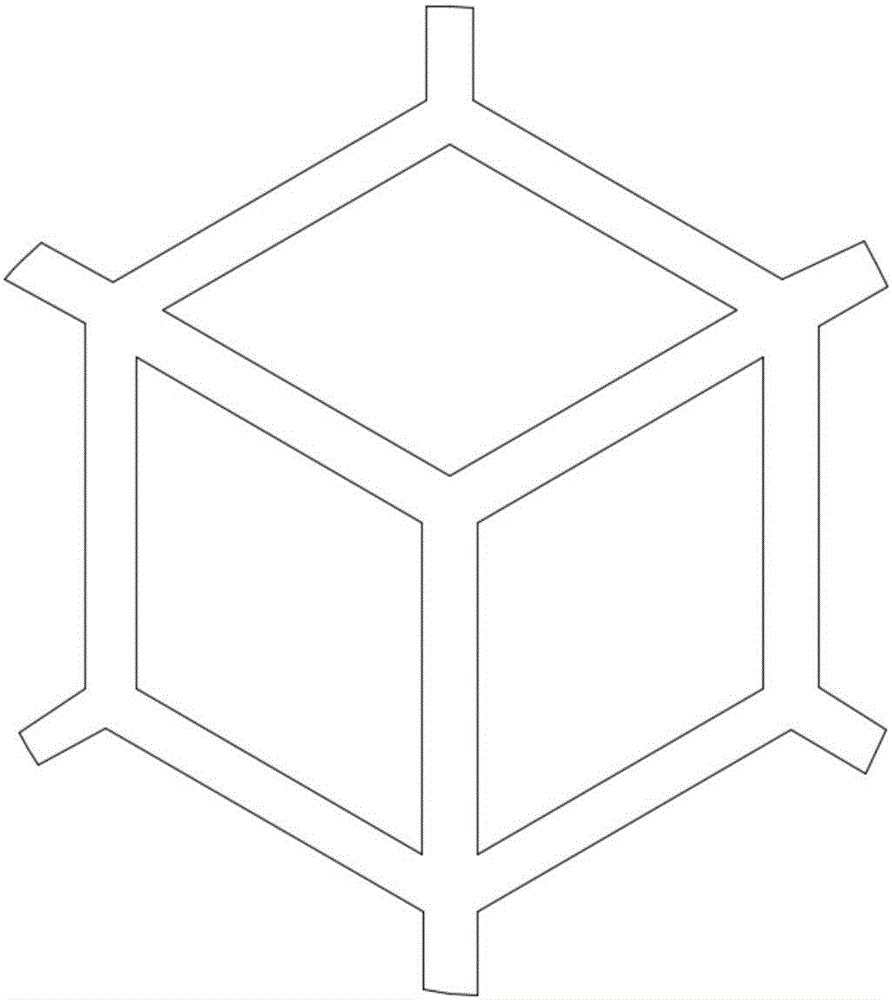

[0052] Step 2) Based on the digital model in step 1), the photosensitive resin is used to manufacture the corresponding polymer model by the method of additive manufacturing, as a personalized and customized network porous carbon precursor 1, see image 3 shown;

[0053] Step 3) Select calcium oxide (the oxide can also be replaced by other above-mention...

Embodiment 2

[0058] see Figure 1 to Figure 6 , the present invention is a kind of personalized mesh porous carbon and preparation method thereof, comprising the following steps:

[0059] Step 1) Use 3D design software to design the outline and internal pore structure of the customized porous scaffold digital model. The microscopic pores inside the scaffold are composed of polyhedral units, and the diameter of the inscribed circle on each face of the polyhedron forming the network porous digital model is 0.2 ~4mm, the diameter of the inscribed circle in the cross section of the polyhedral connecting rod is 0.2~3mm, see figure 2 shown;

[0060] Step 2) Based on the digital model in step 1), the photosensitive resin is used to manufacture the corresponding polymer model by the method of additive manufacturing, as a personalized and customized network porous carbon precursor 1, see image 3 shown;

[0061] Step 3) Select iron powder (the elemental powder can also be replaced by other abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com