Rolled product processing apparatus

A processing device and technology for rolled products, applied in the field of rolled product processing devices, can solve problems such as pole piece collapse, reduction of cell processing quality, and wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

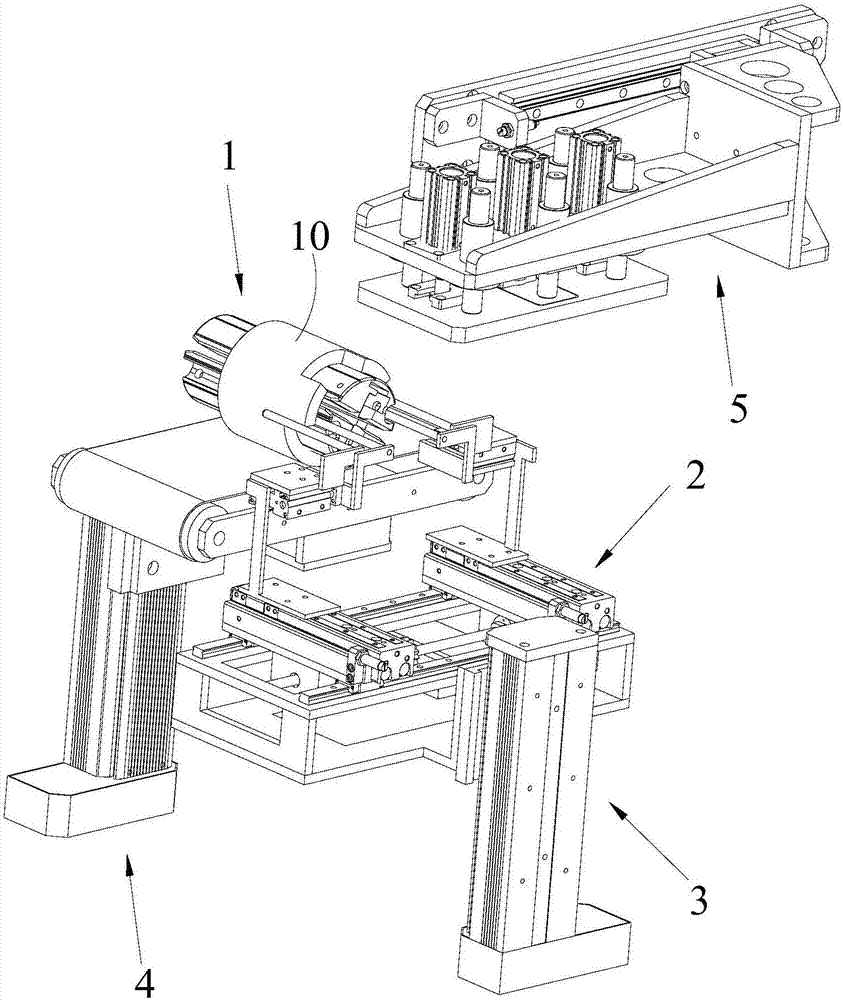

[0073] Such as Figure 1-6 As shown, the present application provides a rolling product processing device, and the rolling product may be a paper roll, a plastic roll, etc., and the present application takes a wound battery as an example for illustration.

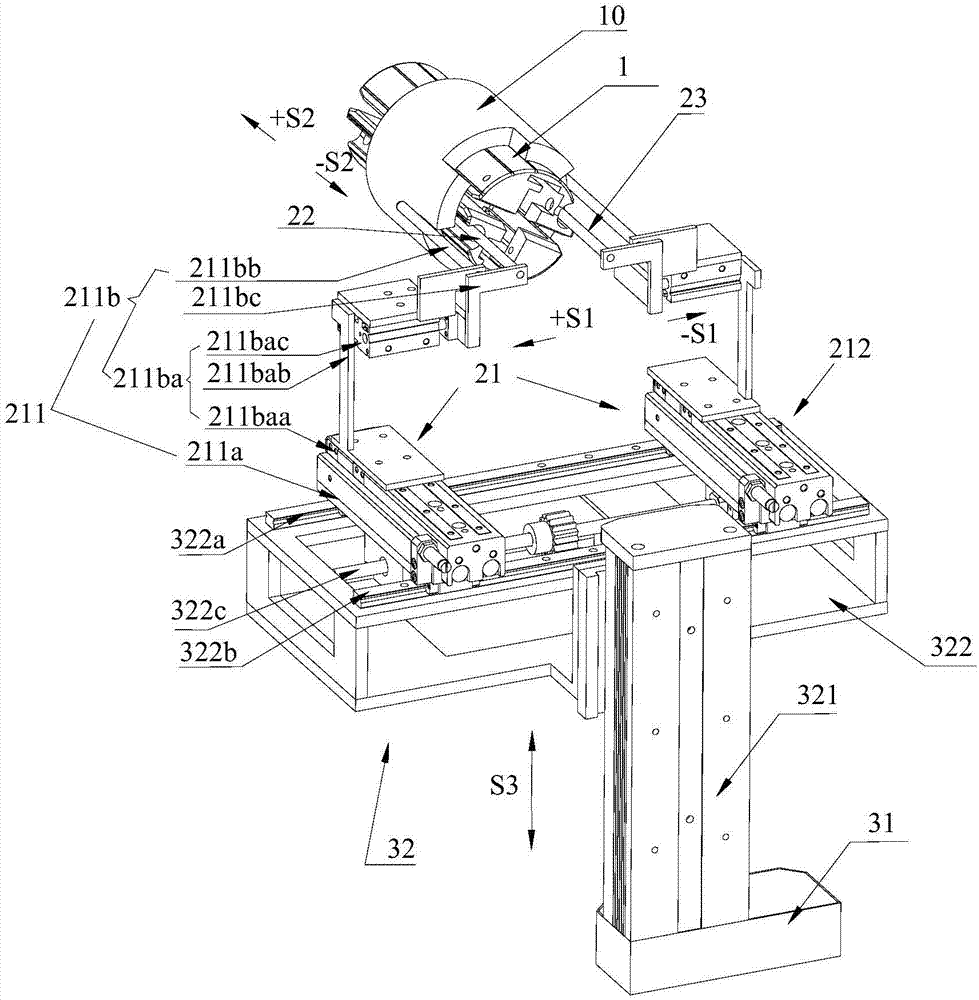

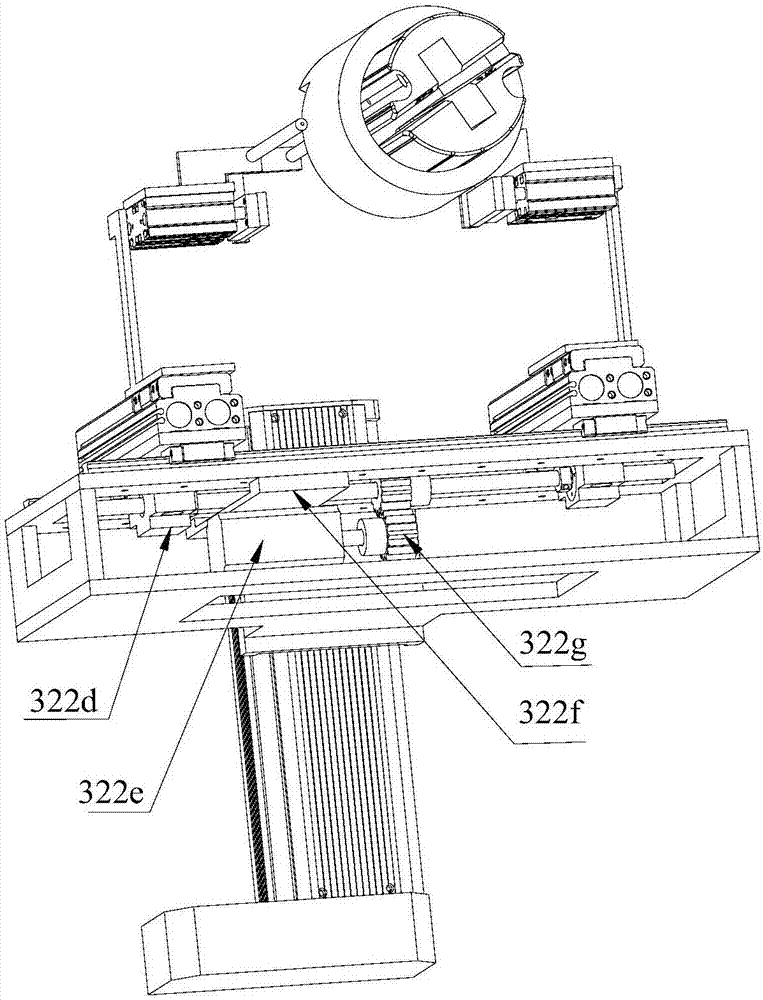

[0074] The processing device includes a rolling needle 1 and a shaping mechanism 2. The rolling needle 1 is used to roll the pole pieces into the battery core 10, and the shaping mechanism 2 is used to shape the battery core 10 to avoid shrinkage and deformation of the pole pieces in the battery core 10. , reducing the processing quality of the battery cell 10 .

[0075] Specifically, such as figure 2 As shown, the shaping mechanism 2 includes a movable part 21, a first acting part 22 and a second acting part 23, wherein the movable part 21 is connected with at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com