Low-shrinkage shaping high-coaxiality cable cladding production line

A technology of cable coating and coaxiality, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as uneven coating of coating materials, achieve reduced mutual adhesion, small shrinkage deformation, and improved The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

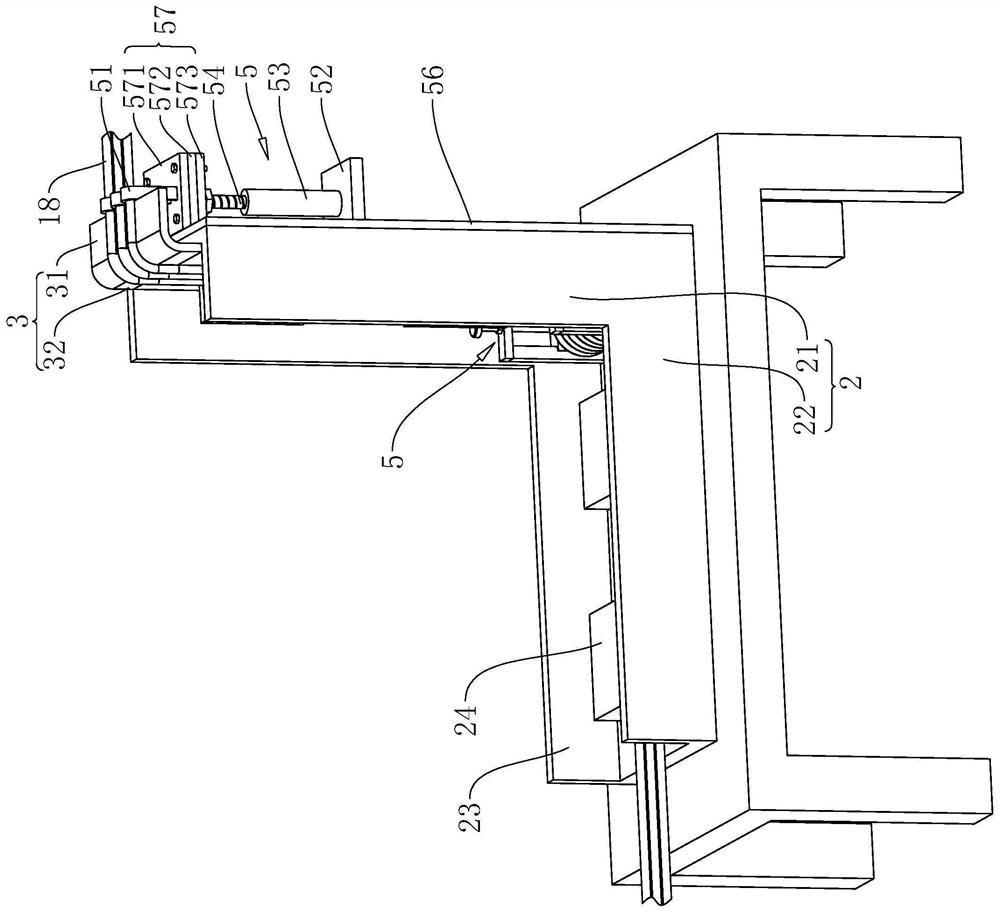

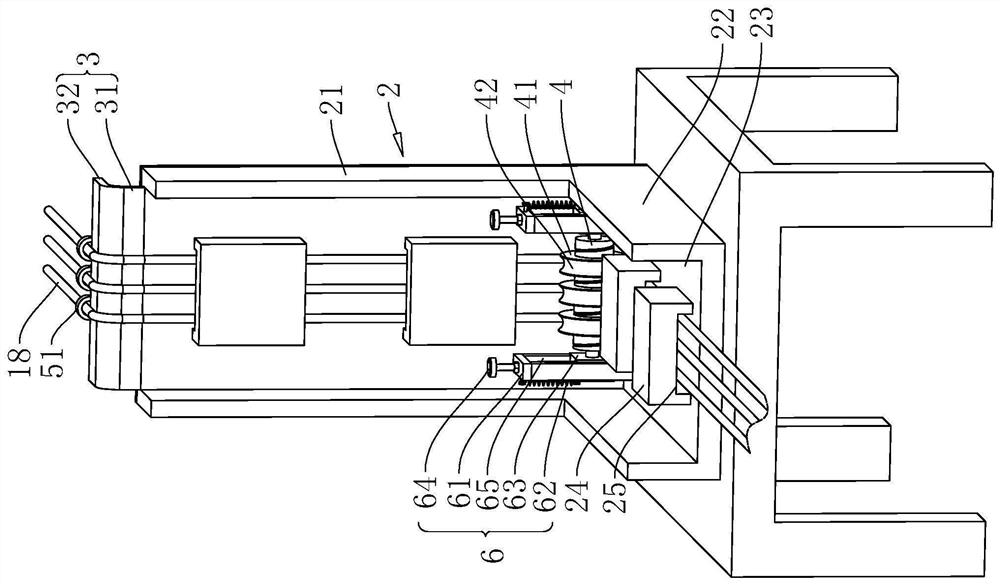

[0034] The following is attached Figure 1-4 The application is described in further detail.

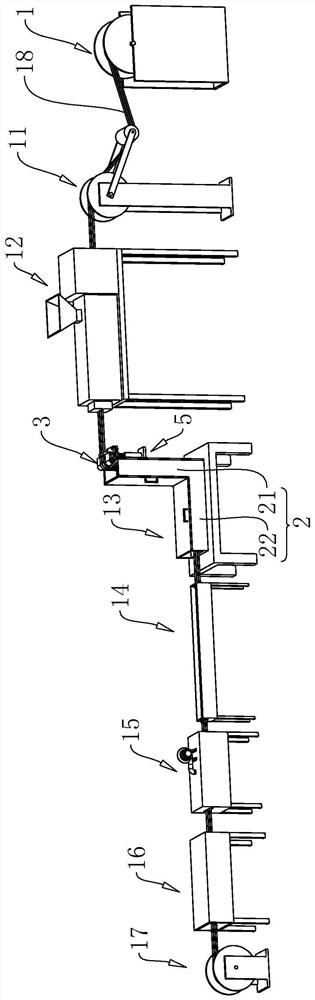

[0035] The embodiment of the present application discloses a low shrinkage shaping and high coaxiality cable coating production line. refer to figure 1 , a low-shrinkage shaping high-coaxiality cable coating production line includes a feeding device 1, a pressing device 11, an extrusion device 12, a presetting device 13, a cooling device 14, a drying device 15, and a driving device 16 arranged in sequence. And receiving device 17. The feeding device 1 can carry out feeding for the entire production line, and the cable 18 coated with the shielding layer is wound on the feeding device 1 . The pressing device 11 can tension the cable 18 during feeding, and the extruding device 12 can extrude and coat the cable 18 through the coating material, and the coating material can be solidified on the peripheral wall of the cable 18 to form a sheath. The presetting device 13 can facilitate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com