Weatherproof glass fiber reinforced PA66 common railway track gauge block material and preparation method thereof

A technology of gauge block and ordinary iron, which is applied in the field of weather-resistant glass fiber reinforced PA66 ordinary rail gauge block material and its preparation, can solve the problems of high water absorption, high cost, poor dimensional stability, etc., and achieve strong hydrolysis resistance , Reduce water absorption, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

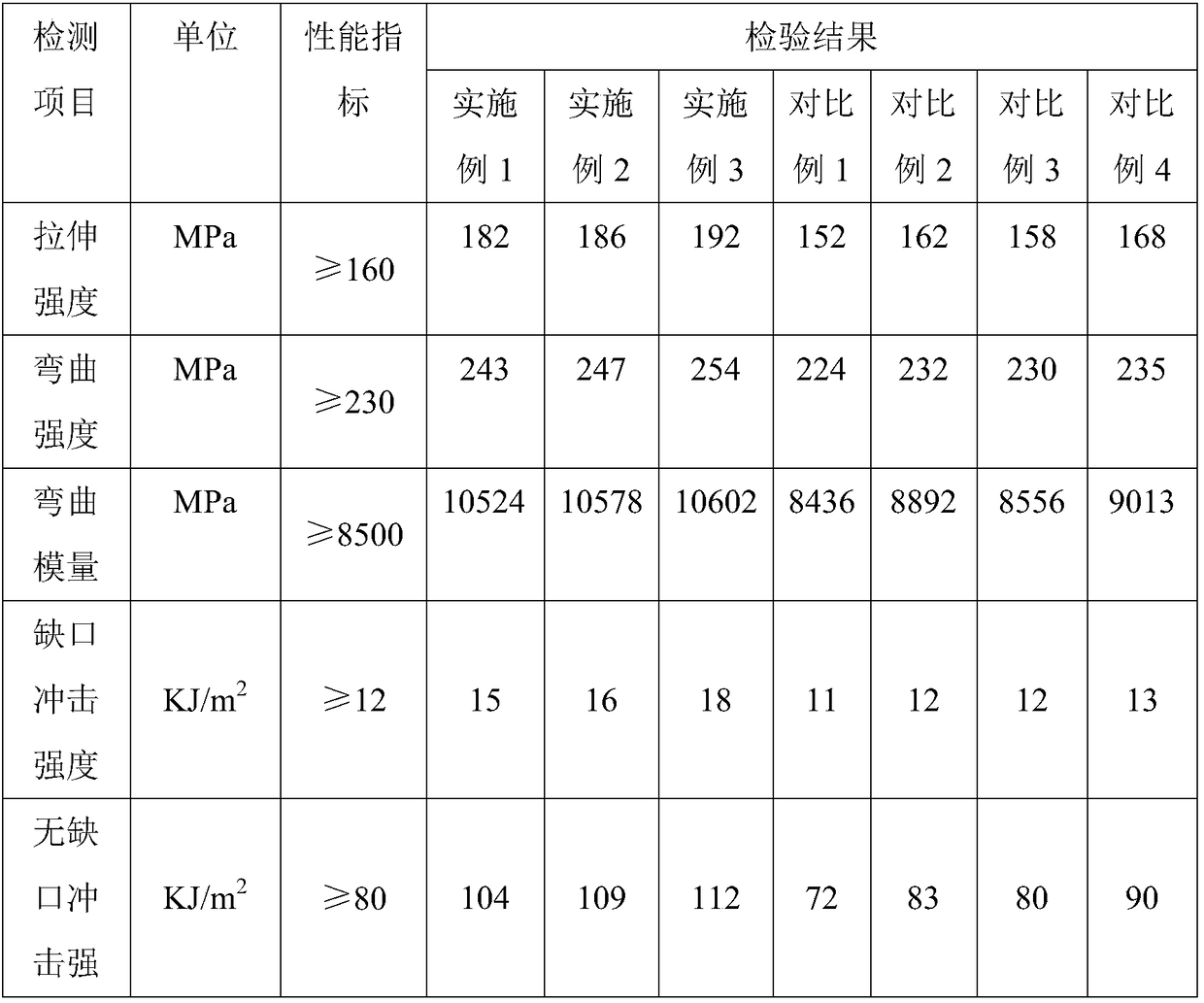

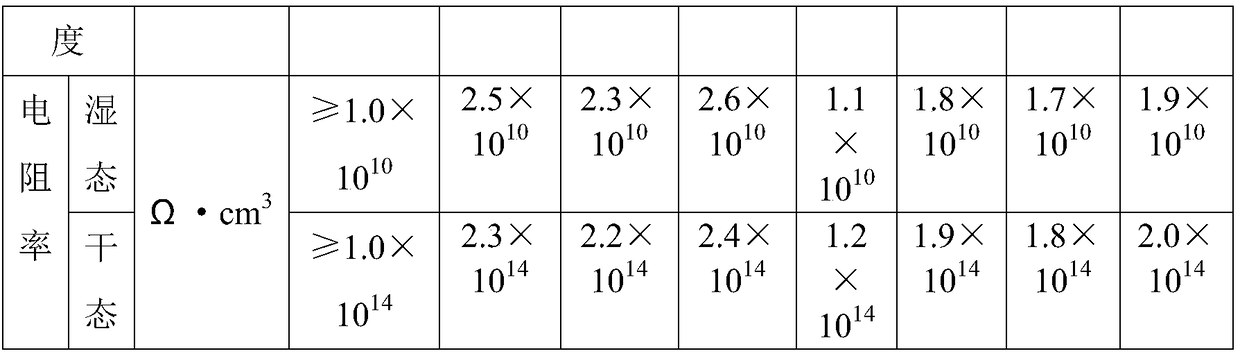

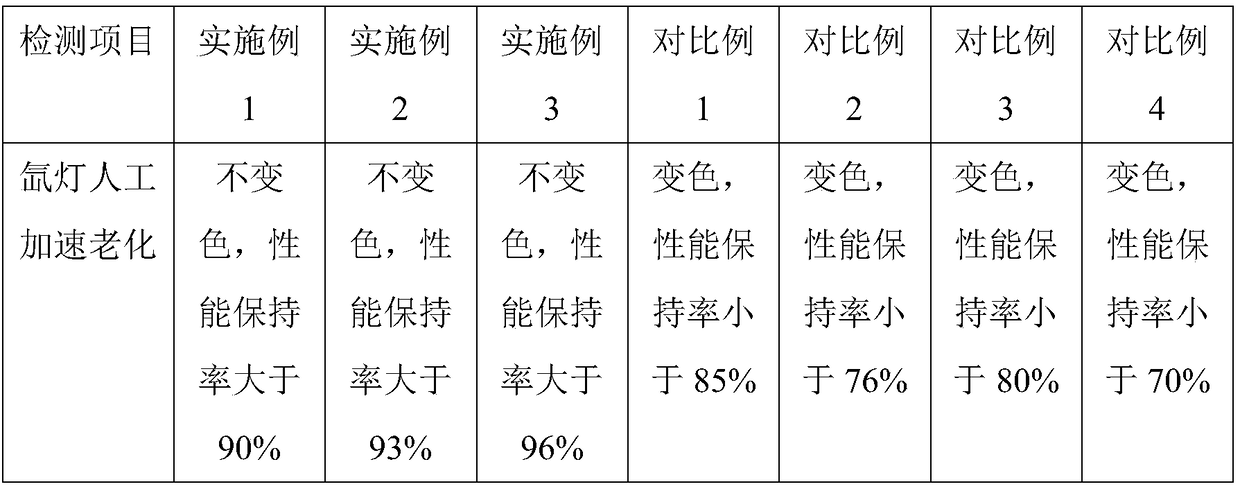

Examples

Embodiment 1

[0030] Embodiment 1. A kind of weather-resistant glass fiber reinforced PA66 general railway track gauge block material

[0031] The weather-resistant glass fiber reinforced PA66 ordinary rail gauge block material is composed of the following components and their weight percentages: PA66 resin 39.0%, PA6T resin 10.0%, antioxidant 1.0%, lubricant 0.5%, inorganic filler 10.0% , toughening agent 2.0%, weathering agent 0.5%, glass fiber 37%; Described antioxidant is made up of antioxidant 1010 and antioxidant 1098 by weight ratio 3:5; Described lubricant is silicone; Described The toughening agent is a toughening agent POE; the inorganic filler is a particle size of 600 mesh glass beads; the weather resistance agent is 2'-(2'-hydroxyl-3'-tert-butyl-5'-methylbenzene base)-5-chlorobenzotriazole.

[0032] Preparation:

[0033] S1 Mix PA66 resin, PA6T resin, antioxidant, lubricant, inorganic filler, toughening agent and weathering agent at a speed of 700r / min for 3 minutes to obtain...

Embodiment 2

[0035] Embodiment 2, a weather-resistant glass fiber reinforced PA66 ordinary railway track gauge block material

[0036]The weather-resistant glass fiber reinforced PA66 ordinary rail gauge block material is composed of the following components and their weight percentages: PA66 resin 52.8%, PA6T resin 5.0%, antioxidant 0.6%, lubricant 0.3%, inorganic filler 5.0% , toughening agent 1.0%, weathering agent 0.3%, glass fiber 35%; Described antioxidant is made up of antioxidant 1010 and antioxidant 1098 by weight ratio 5:3; Described lubricant is OP wax; Described The toughening agent is toughening agent POE; the inorganic filler is glass microspheres with a particle size of 3000 mesh; 5-Chlorobenzotriazole.

[0037] Preparation:

[0038] S1 Mix PA66 resin, PA6T resin, antioxidant, lubricant, inorganic filler, toughening agent and weathering agent at a rotating speed of 900r / min for 6 minutes to obtain a mixture;

[0039] S2 Add glass fibers to the mixture obtained in step S1,...

Embodiment 3

[0040] Embodiment 3, a weather-resistant glass fiber reinforced PA66 ordinary railway track gauge block material

[0041] The weather-resistant glass fiber reinforced PA66 ordinary rail gauge block material is composed of the following components and their weight percentages: PA66 resin 46.1%, PA6T resin 7.0%, antioxidant 0.7%, lubricant 0.3%, inorganic filler 8.0% , toughening agent 1.6%, weathering agent 0.3%, glass fiber 36%; Described antioxidant is made up of antioxidant 1010 and antioxidant 1098 by weight ratio 3:4; Described lubricant is silicone; Described The toughening agent is toughening agent POE; the inorganic filler is glass microspheres with a particle size of 1500 mesh; the weather resistance agent is 2-hydroxyl-4-n-octyloxybenzophenone.

[0042] Preparation:

[0043] S1 Mix PA66 resin, PA6T resin, antioxidant, lubricant, inorganic filler, toughening agent and weathering agent at a rotating speed of 800r / min for 5 minutes to obtain a mixture;

[0044] S2 Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com