A kind of pvc sole foam material

A technology of foaming materials and foaming agents, applied in shoe soles, footwear, applications, etc., can solve the problems of brittleness and poor flexibility, impact resistance and heat resistance, poor light stability, etc., to reduce density and shrinkage deformation rate, and the effect of improving elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

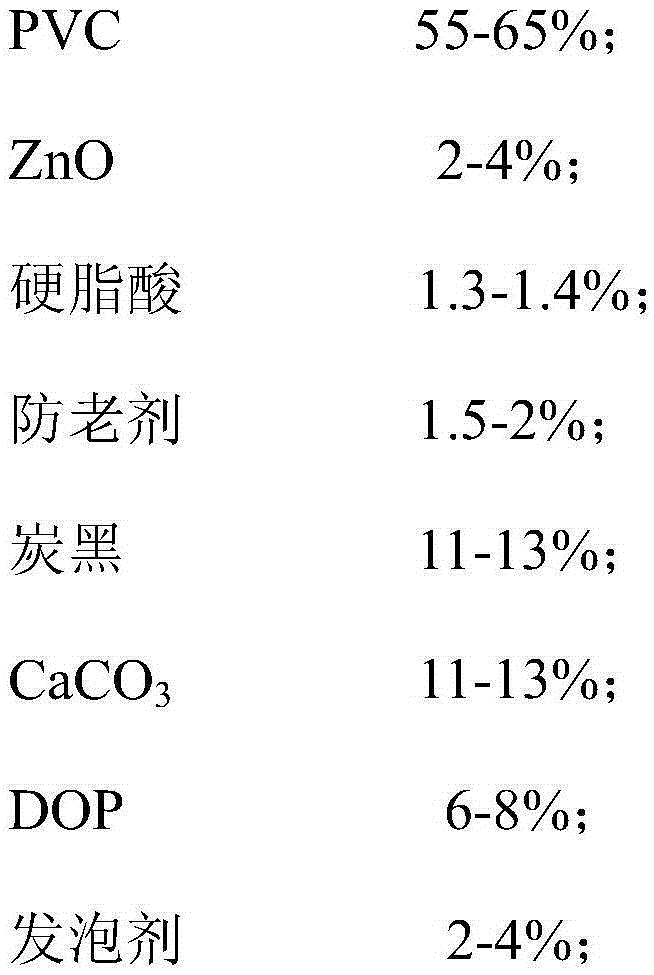

[0015] Weigh 55g of PVC material, ZnO 4g, HSt 1.3g, antioxidant 2g, carbon black 13g, CaCO 3 13g, DOP 8g, foaming agent 3.7g, put PVC material, DOP, HSt in a high-speed mixer and mix evenly, plasticize and roll on the double-roller plastic mixer to become transparent, add foaming agent, ZnO, anti-aging agent, carbon black, CaCO 3 Mix evenly, enlarge the roller distance to release the sheet, cut it into a 10mm sheet, place the sheet on a flat carding machine for molding and foaming, the foaming temperature is 160-170°C, the foaming pressure is 8-10MPa, and the foaming time is 10 -15min.

Embodiment 2

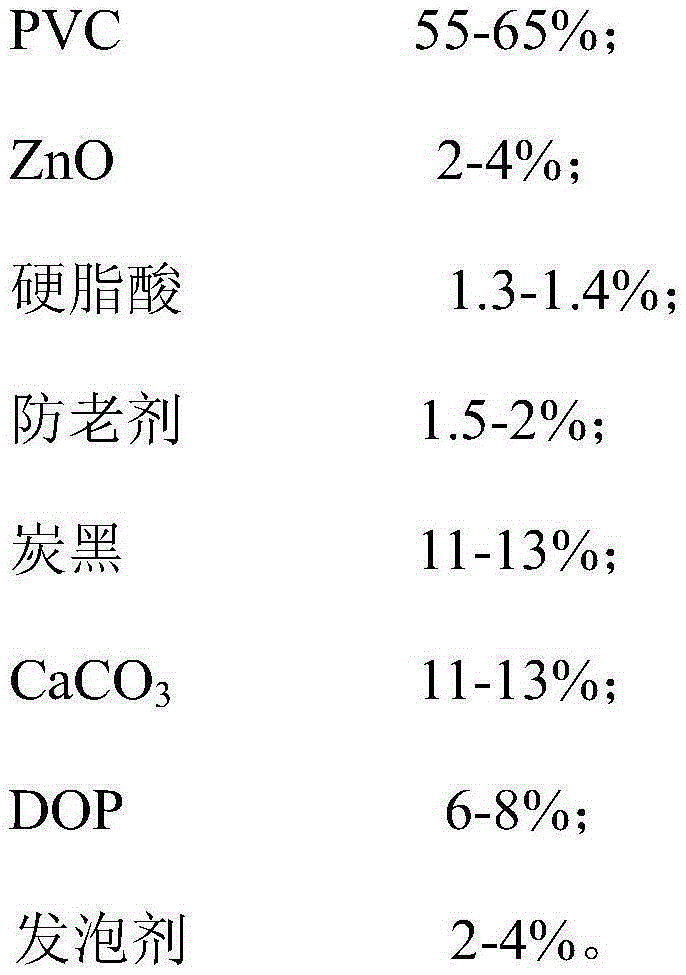

[0017] Weigh 65g of PVC material, ZnO 2g, HSt 1.4g, antioxidant 1.6g, carbon black 11g, CaCO 3 11g, DOP6g, foaming agent 2g, put PVC material, DOP, HSt in a high-speed mixer and mix evenly, after plasticizing and wrapping rolls on a double-roller plastic mill to become transparent, add foaming agent, ZnO, anti-aging agent, Carbon black, CaCO 3 Mix evenly, enlarge the roller distance to release the sheet, cut it into a 10mm sheet, place the sheet on a flat carding machine for molding and foaming, the foaming temperature is 160-170°C, the foaming pressure is 8-10MPa, and the foaming time is 10 -15min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com