Method for directly titrating and forming ceramic microspheres through gel casting of track

A ceramic microsphere and gel injection molding technology, which is applied in ceramic molding machines, die-casting molds, manufacturing tools, etc., can solve the problems of low uniformity of ceramic microspheres, cumbersome production process, and low production efficiency, and achieve easy automation The effect of production, uniform internal structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

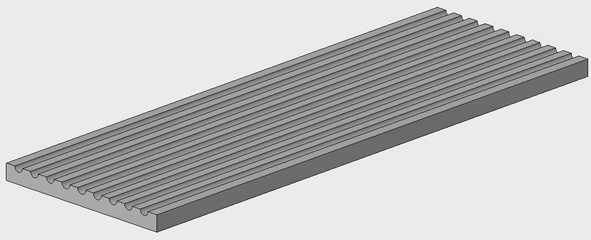

[0030] Embodiment: first process the track disk, the track disk is made of stainless steel, the length is 20m, and the thickness is 10mm. There are 9 semicircular tracks, the diameter of the semicircular track is 5mm, and the distance between two adjacent semicircular tracks is 5mm. mm, carry out sandblasting treatment on the surface of the orbital disk, the surface roughness of the orbital disk after sandblasting is less than 1.6μm, and then paste a heating tape on the surface of the orbital disk and spray hydrophobic paint, so that the heating belt can heat the orbital disk at 80°C 3h, drying the hydrophobic coating.

[0031] Then prepare raw materials, weigh ZrO with an average particle size of 0.1 μm 2 Powder 800g, and according to the mass percentage, weigh the ZrO 2 The total mass ratio of the powder is 2.3% of acrylamide, 0.25% of N-N'methylenebisacrylamide, 1.2% of ammonium polycarboxylate, 0.45% of ammonium persulfate and 0.17% of tetramethylethylenediamine ; Add acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com