Orthogonal three-axis machine tool

A machine tool, Z-axis technology, applied in the field of machine tools, can solve the problems of high manufacturing cost and high processing cost of orthogonal three-axis machine tools, and achieve the effect of reducing labor intensity and skill requirements, ensuring machining accuracy, and accurately ensuring straightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

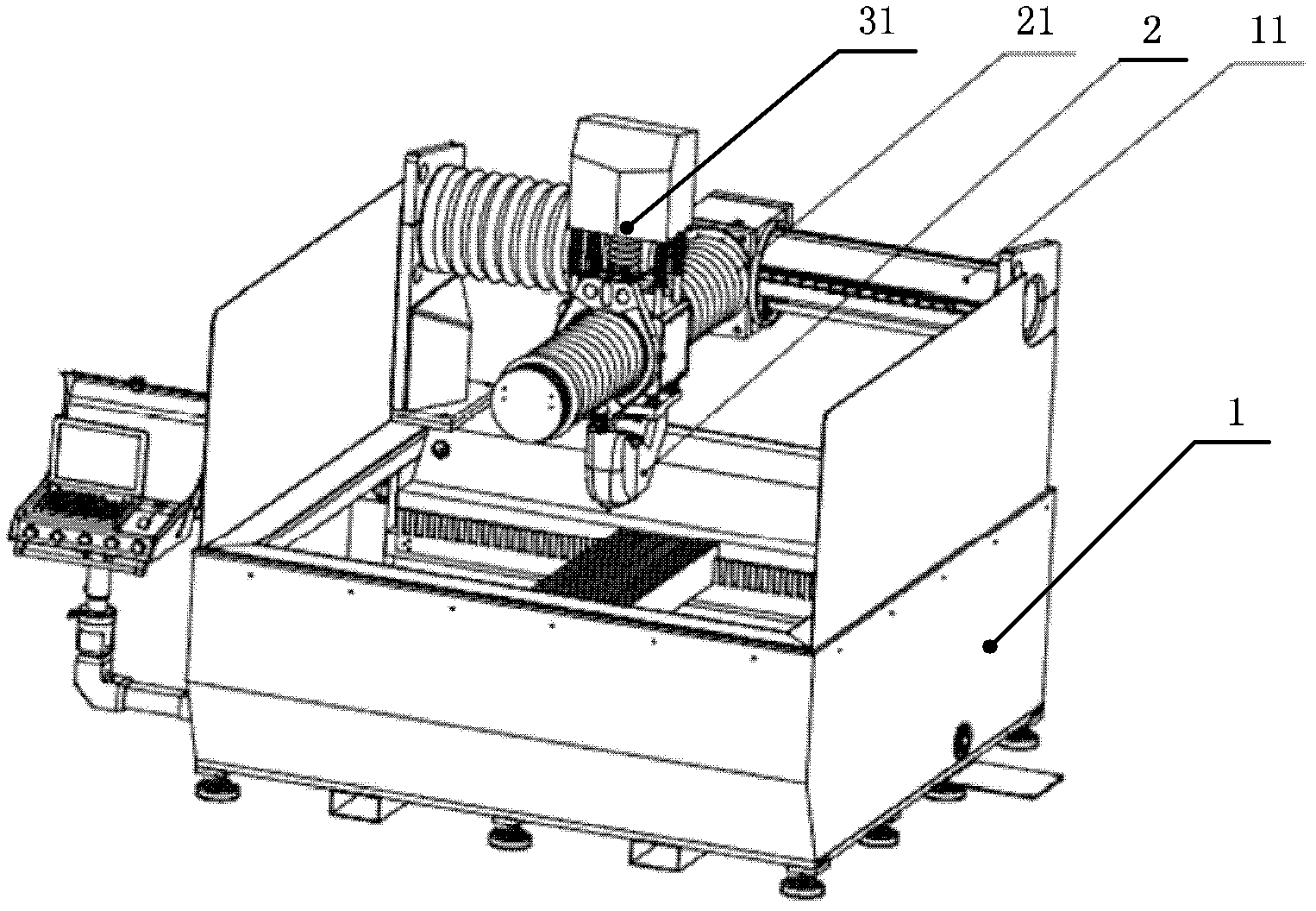

[0035] like figure 1 As shown, the present invention provides an orthogonal three-axis machine tool, including a bed 1, a machining head assembly 2 and an XYZ three-axis motion assembly; the machining head assembly 2 is driven by the XYZ three-axis motion assembly to move in three directions of XYZ , so as to complete the processing task. The machining head assembly 2 can be designed in different ways according to different machining requirements, and the present invention does not limit or describe the machining head assembly 2 .

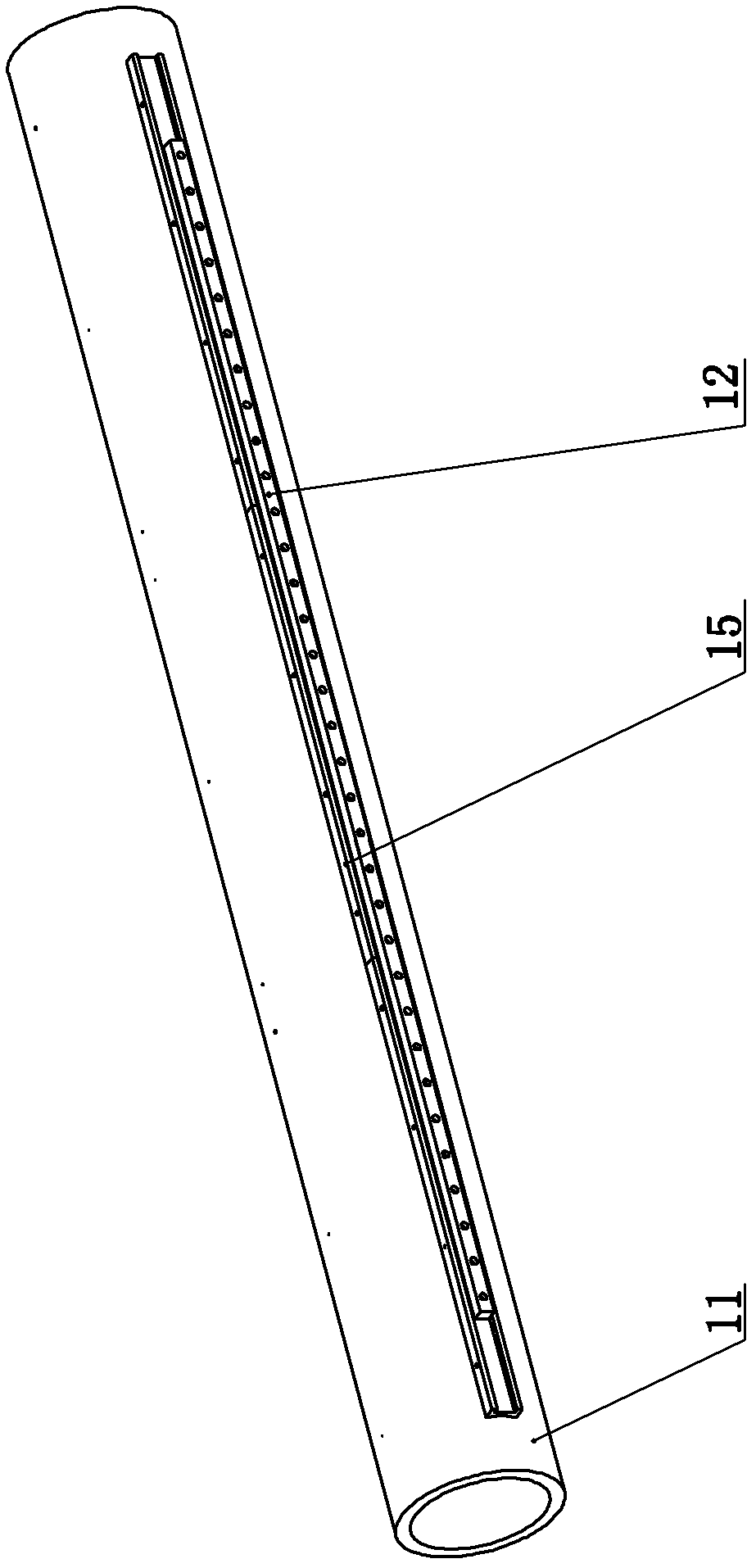

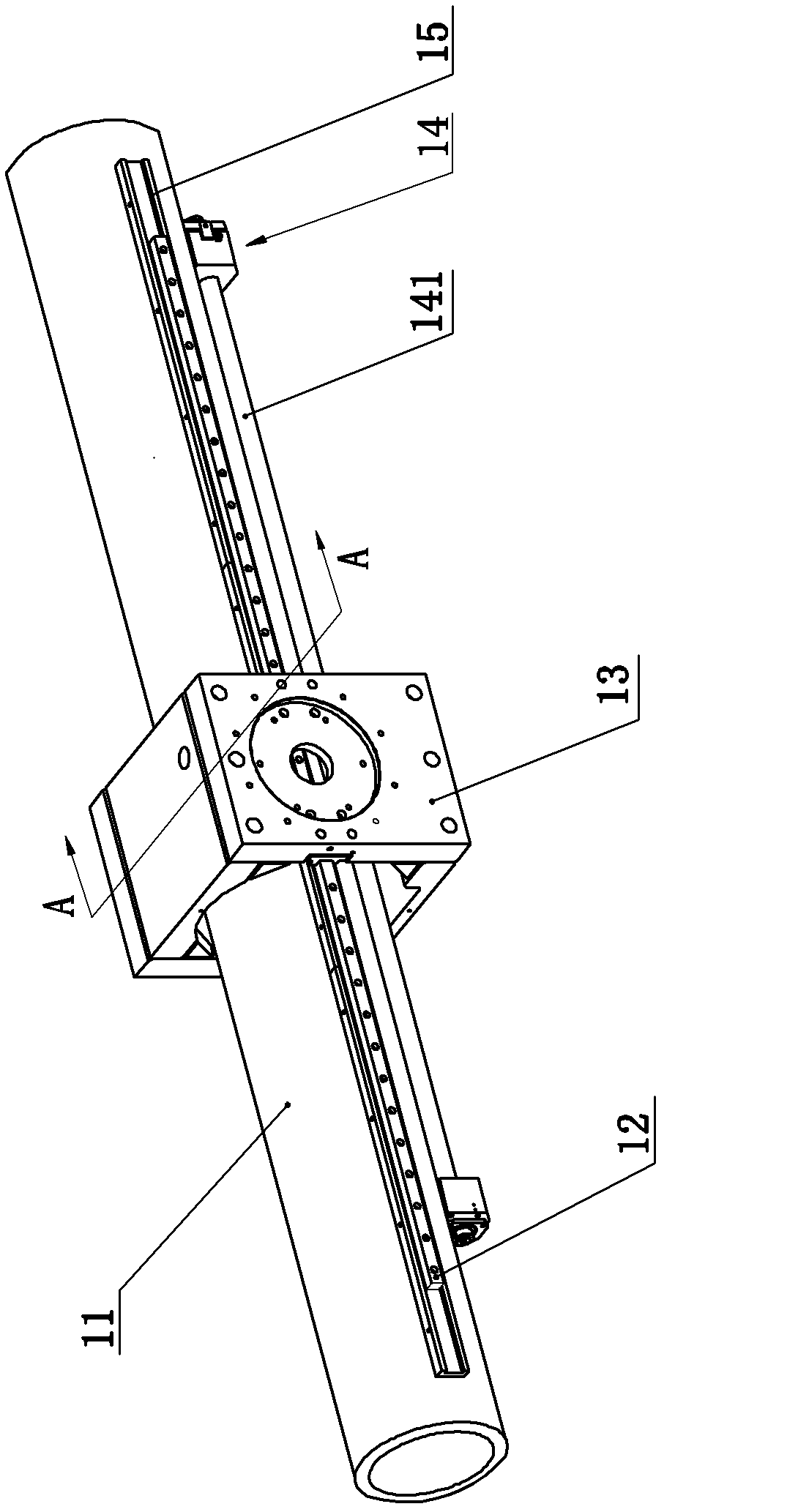

[0036] The XYZ three-axis motion assembly of the present invention includes an X-axis beam 11, a Y-axis cantilever 21 and a Z-axis sliding frame 31 that are orthogonal to each other; both ends of the X-axis beam 11 are fixedly installed on the bed 1 through two uprights , the Y-axis cantilever 21 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com