Aluminum template welding production line

A welding production line and aluminum formwork technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of operation, stacking by manual operation, low degree of precision, and low degree of automation, so as to reduce labor The steps of sticking code, increasing the accuracy of feeding, and the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below, the present invention will be described more clearly and completely with reference to the drawings and specific embodiments.

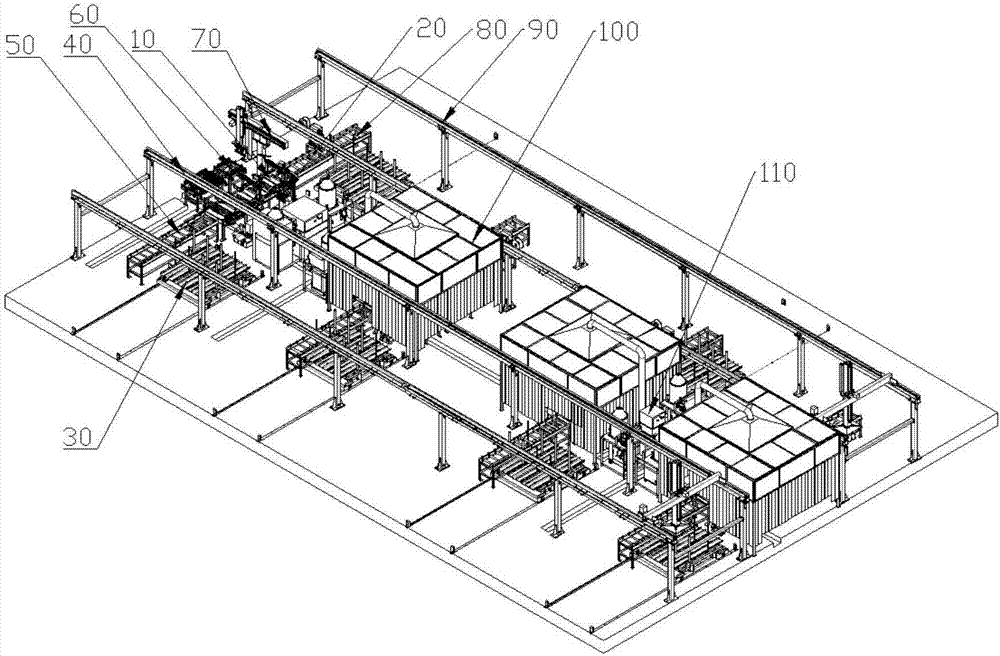

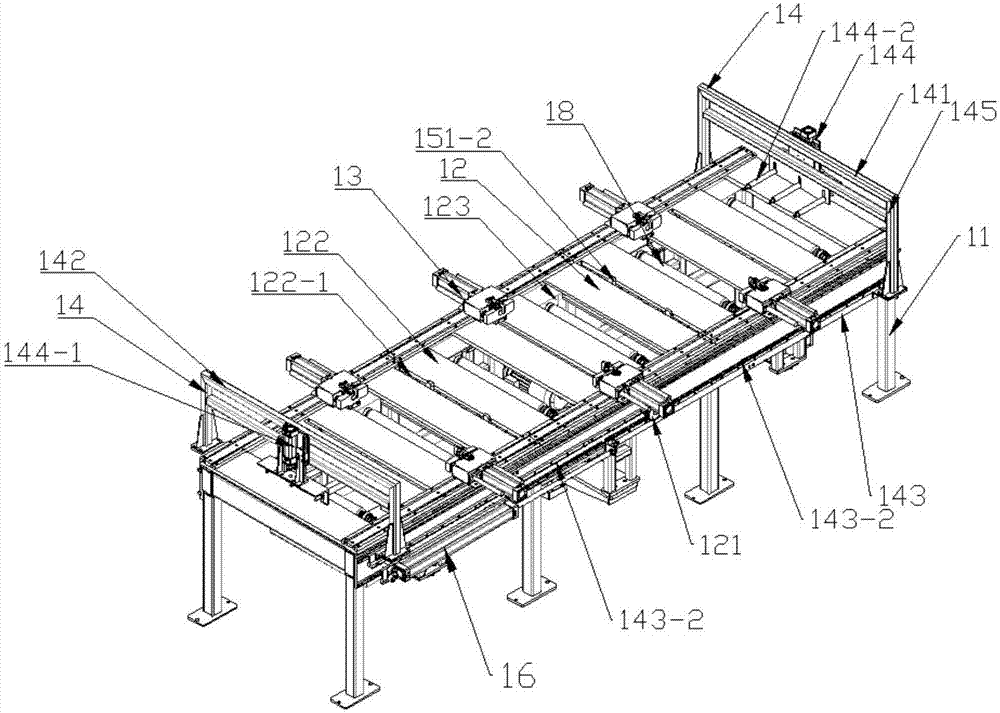

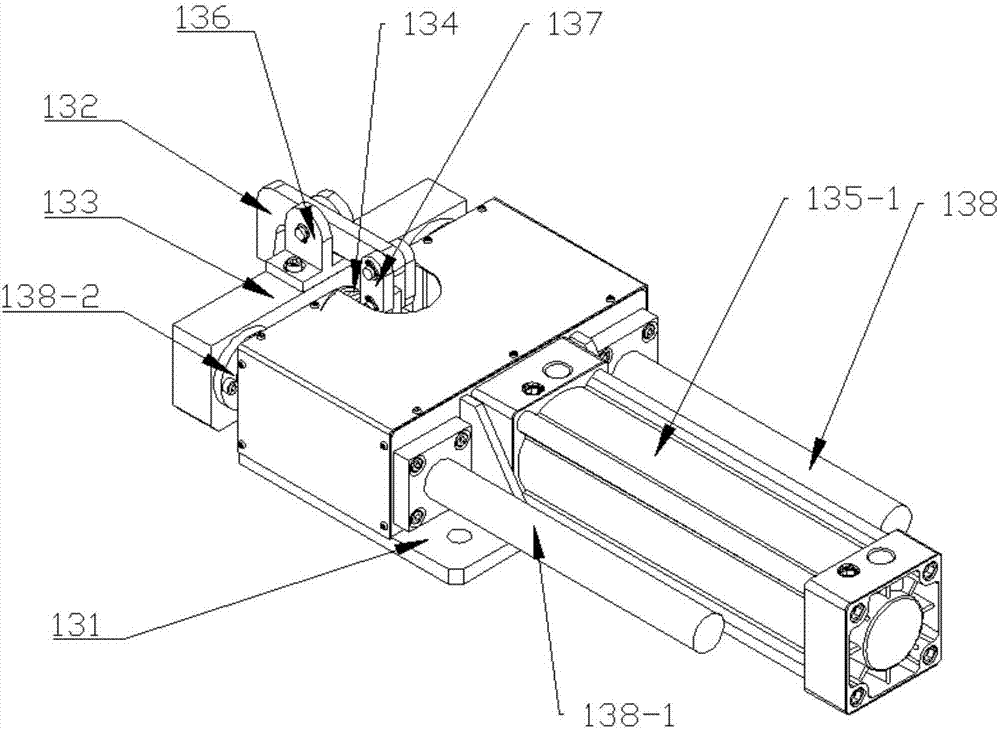

[0048] An aluminum template welding production line, including a feeding system, a welding system, and a feeding system. Special plane 70; welding system includes welding tooling platform 10, welding robot 20, and unloading system includes unloading roller rack 80, finished product palletizing gantry 90; loading gantry 40, small piece feeding special plane 70 and finished product palletizing gantry 90 are all composed of PLC integrated control, driven by servo motor and reducer.

[0049] The welding eager man in the present invention includes three parts: the robot body, the robot control cabinet (KRC4), and the teaching box (KCP) to ensure the normal and precise operation of the system. The casting robot is resistant to high temperature and dust, and the payload is 60KG. Radius 2033, the robot controller KRC4 is based on the windows ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com