Wear-resistant and thermally stable alumina coating carrier

A technology of alumina coating and thermal stability, which is applied in the direction of catalyst carrier, metal/metal oxide/metal hydroxide catalyst, inorganic chemistry, etc. The overall cracking of the layer and other problems can be achieved, and the effects of good hydrothermal stability, increased wear resistance, and reduced shrinkage and deformation can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

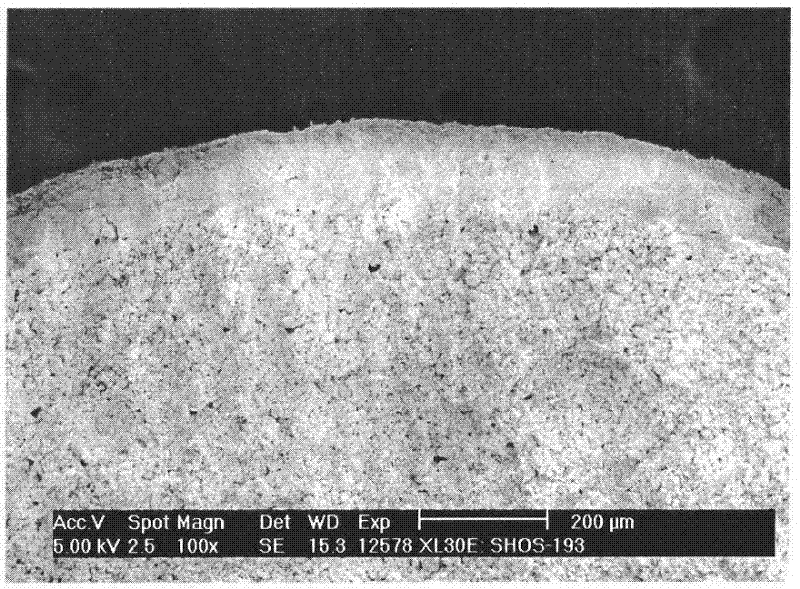

[0025] Dissolve pseudo-boehmite in water to make a 15% alumina sol. 40 grams of the above alumina sol, 0.3 grams of samarium oxide, 4 grams of wollastonite, and 60 grams of 2% PVA solution. Then add 60 grams of gamma-alumina powder (specific surface area 230 meters 2 / gram). After stirring for about ten minutes, the slurry was ball milled at room temperature so that the particle size was controlled below 5 microns. The slurry was sprayed onto cordierite pellets with a particle size of 4 mm, and the coating loading was controlled by controlling the spraying time. After spraying, dry at 80°C for 2 hours, then raise the temperature to 120°C and dry again for 2 hours, and finally bake at 800°C for 10 hours to obtain a layered composite carrier A. The physical and chemical properties are shown in Table 1.

Embodiment 2

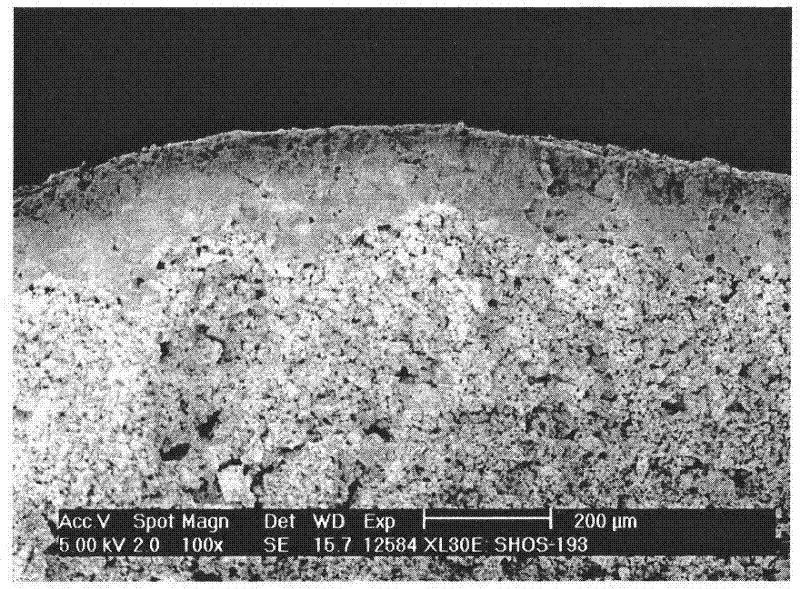

[0027] 40 grams of 20% alumina sol, 0.5 grams of yttrium oxide, 0.5 grams of thulium oxide, 2.0 grams of diopside, 60 grams of 3% hydroxypropyl cellulose solution, 40 grams of ultrafine θ-Al 2 o 3 (Specific surface area 180 meters 2 / gram) powder, be prepared into slurry according to the mode described in embodiment 1, control slurry granularity below 5 microns. The slurry was sprayed onto mullite pellets with a particle size of 4 mm, dried again at 150°C for 2 hours, and finally calcined at 1000°C for 4 hours to obtain a layered composite carrier B. The physical and chemical properties are shown in Table 1.

Embodiment 3

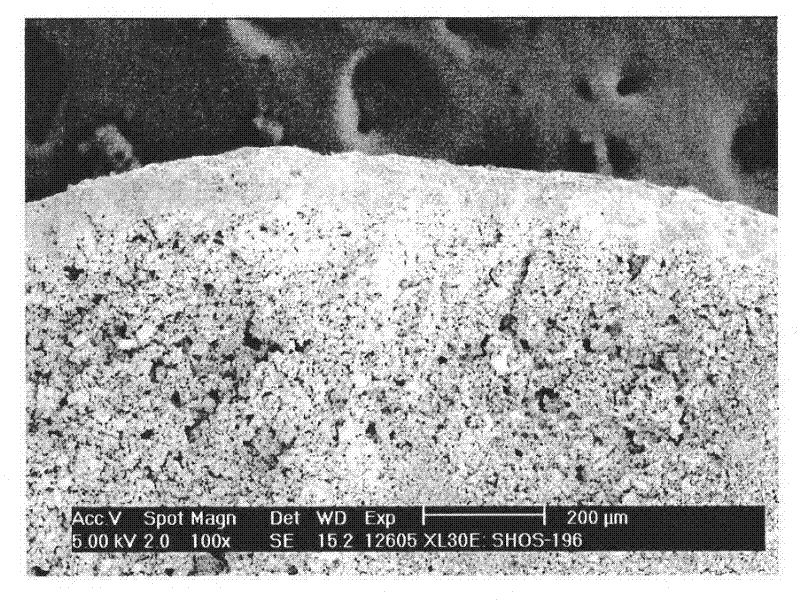

[0029] 36 grams of alumina sol (containing 25% by mass of alumina), 0.8 grams of niobium oxide, 60 grams of 4% CMC solution, 5 grams of magnesium aluminate, 2.5 grams of calcium silicate, 0.5 grams of clay, 50 grams of -Al 2 o 3 powder (specific surface area 160 m 2 / gram), the slurry is obtained in the manner described in Example 1, and the slurry particle size is controlled below 5 microns. Slurry spraying onto δ-Al with a particle size of 4 mm 2 o 3 dry at 80°C for 6 hours, and finally bake at 950°C for 6 hours to obtain a layered composite carrier C, whose physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com