Device and method for wirelessly detecting welding parameters

A welding parameter and wireless detection technology, applied in the direction of welding accessories, etc., can solve the problems of untimely discovery of welding defects, delay of offline detection, workpiece repair or scrapping, etc., achieve low cost, reduce production cost, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

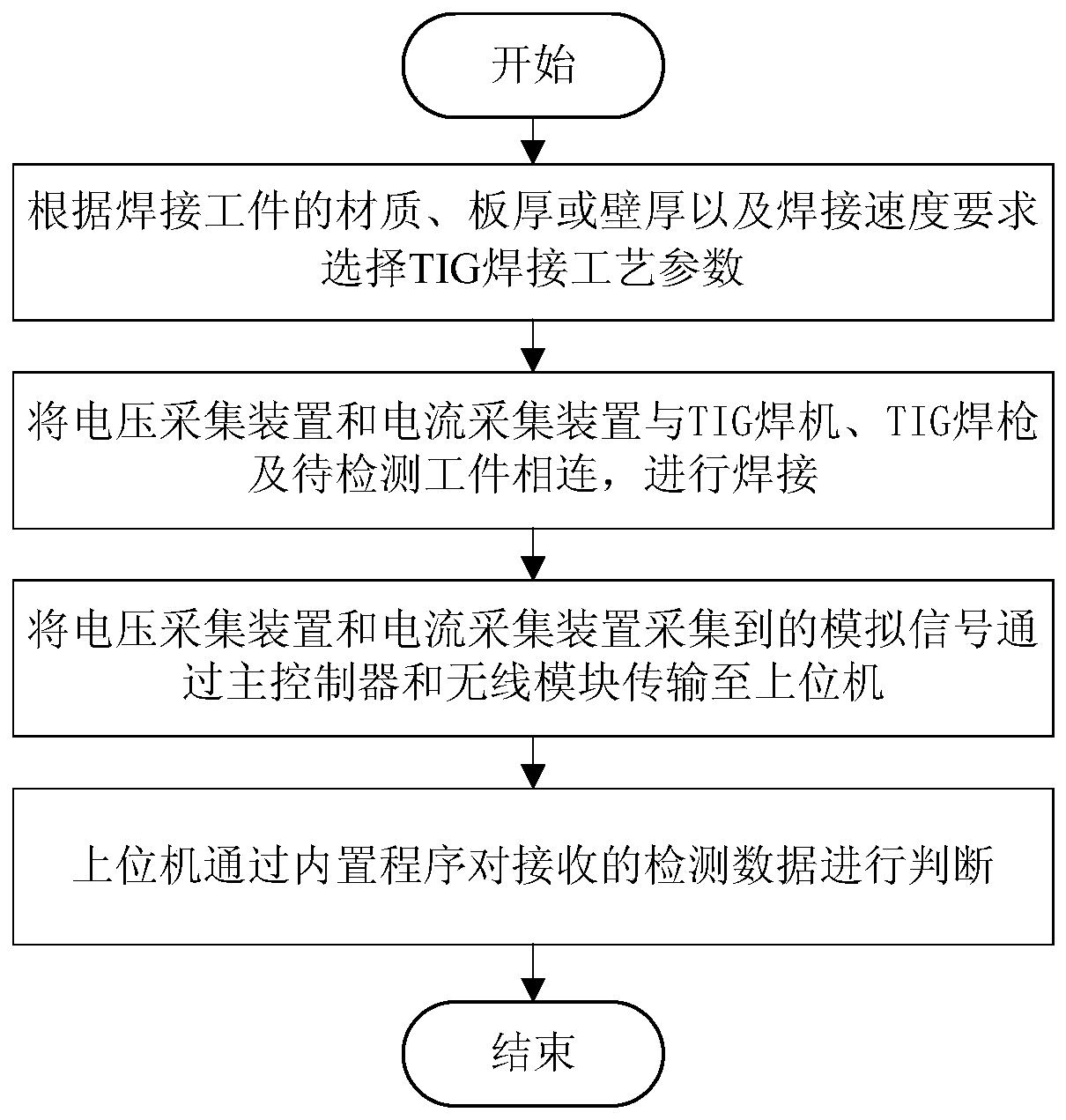

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

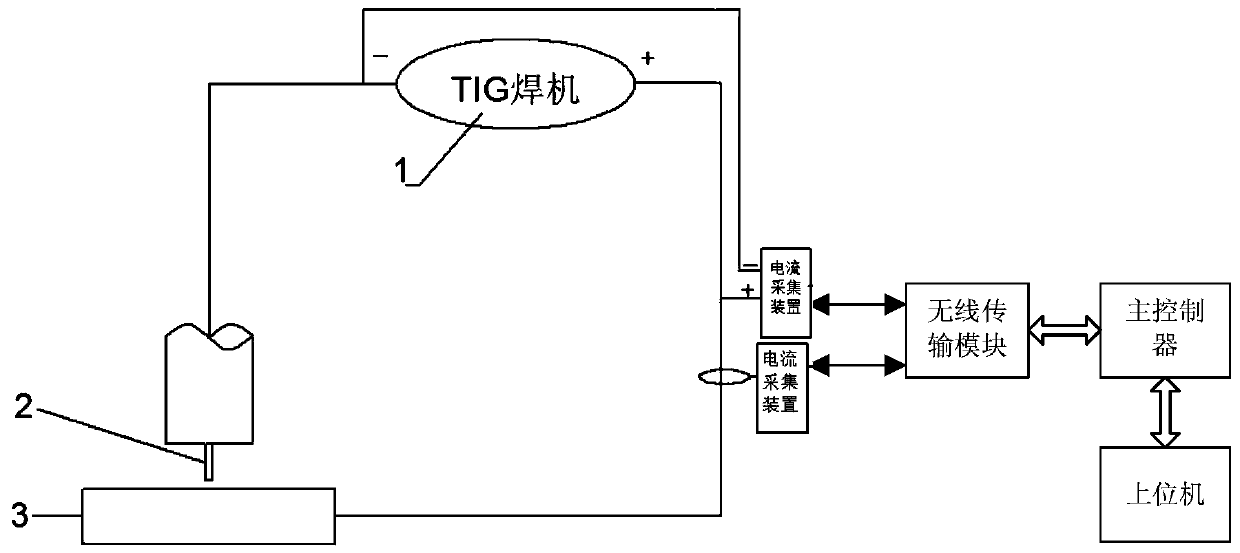

[0023] In this embodiment, a device for wirelessly detecting welding parameters, such as figure 1 As shown, it includes TIG (Tungsten Inert Gas, tungsten argon arc welding) welding machine 1, TIG welding torch 2, voltage acquisition device, current acquisition device, wireless transmission device, main controller and host computer; the TIG welding torch 2 and TIG The welding machine 1 is connected to weld the workpiece 3 to be welded; the positive pole of the voltage acquisition device is connected to the workpiece, and the negative pole is connected to the terminal of the TIG welding torch 2, and the voltage at both ends of the TIG welding torch 2 is collected during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com