Overhead pipe gallery for comprehensive wiring

A technology of integrated wiring and integrated pipe gallery, applied in overhead installation, bridge applications, bridge parts, etc., can solve the problems of large impact on the surrounding environment, impact on park traffic, long spanning time, etc., to reduce construction costs, shorten construction period, The effect of high cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

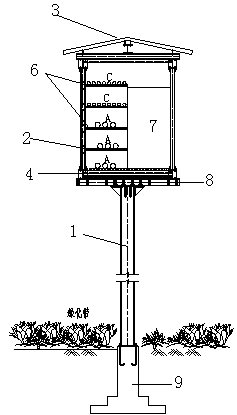

[0041] This embodiment takes the double-sided arrangement of a single pier supporting a single cabin as an example. figure 1 It is understood in conjunction with the structure described in this embodiment.

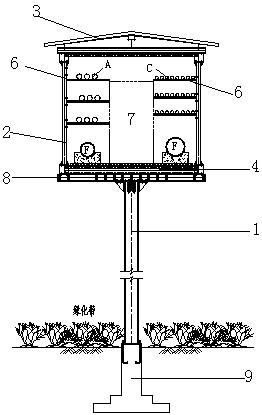

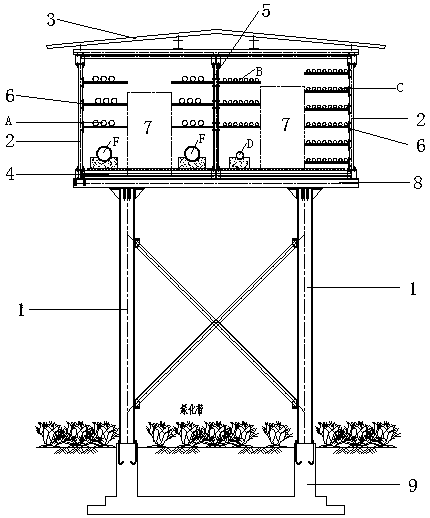

[0042] Refer to the attached figure 2 , a single pier supports a single-cabin overhead type integrated wiring pipe gallery, including a single pier supporting column 1 and a comprehensive pipe gallery, along the direction of the comprehensive pipe gallery, a support column 1 is arranged at an interval of 8-10m. The supporting column 1 is made of steel pipes of equal wall thickness, the specification can be Φ325 / 12, and hot-dip galvanized anti-corrosion is adopted, and the overhead height varies from 4.0m to 6.0m; When the foundation soil is cohesive soil or other strata that can be used as the foundation bearing layer, the foundation shall adopt an independent plate-type pillar foundation; when the foundation soil is soft soil, the pile foundation can be used as the founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com