Device and method for measuring fluid saturation pressure and seepage capacity in porous media

A porous medium and pressure technology, which is applied in the direction of measuring devices, suspension and porous material analysis, permeability/surface area analysis, etc., can solve the problems of complexity, expensive operation of equipment, and low accuracy of measurement methods, and achieve simple equipment and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

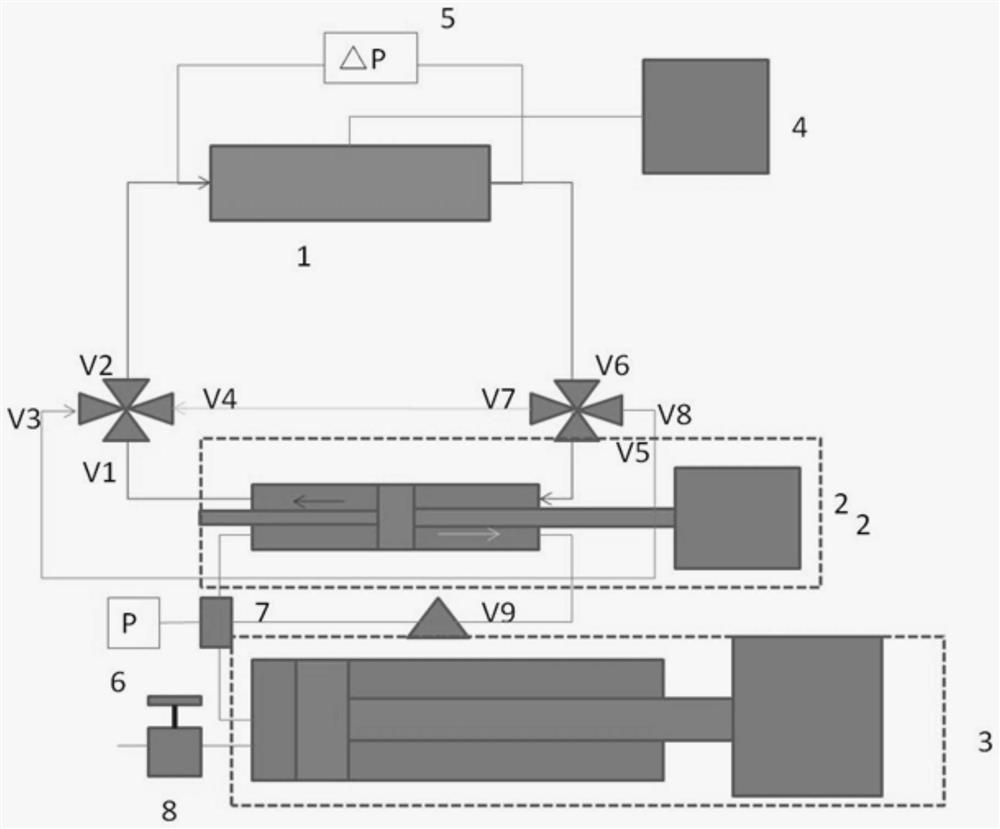

[0043] According to one aspect of the present invention there is provided a device for measuring fluid saturation pressure and seepage capacity in porous media, the device comprising:

[0044] High temperature and high pressure core holder, two-way piston pump, volume adjustment device, pressure collection device and pressure difference collection device;

[0045] Wherein, the volume adjustment device includes a chamber and a piston, one side of the piston is an effective chamber, and the piston can move in the chamber to adjust the volume of the effective chamber;

[0046] Wherein, the liquid to be tested flows into the two-way piston pump through the effective chamber, and the two-way piston pump makes the liquid to be tested flow through the core sample in the high-temperature and high-pressure core holder;

[0047] The pressure collection device is used to collect the real-time pressure of the liquid to be tested. The pressure collection end of the differential pressure co...

Embodiment approach 2

[0070] According to another aspect of the present invention there is provided a method for measuring a device for measuring fluid saturation pressure and seepage capacity in a porous medium, the method comprising:

[0071] Hold the core sample to be tested by the high temperature and high pressure core holder;

[0072] Vacuumize the device, and then adjust the temperature of the device to the experimental temperature;

[0073] Inject the liquid to be tested into the device through the volume adjustment device;

[0074] Control the movement of the piston so that the liquid to be tested flows through both sides of the core sample to be tested, and obtain the pressure of the liquid to be tested at this time, the pressure difference before and after the liquid to be tested flows through the core sample to be tested, the flow rate of the liquid to be tested and the effective chamber volume;

[0075] Based on the pressure of the liquid to be tested, the pressure difference before ...

Embodiment 1

[0087] The device for measuring fluid saturation pressure and seepage capacity in porous media includes: a high temperature and high pressure core holder, a bidirectional piston pump, a volume adjustment device, a pressure acquisition device and a pressure difference acquisition device;

[0088] Wherein, the volume adjustment device includes a chamber and a piston, one side of the piston is an effective chamber, and the piston can move in the chamber to adjust the volume of the effective chamber;

[0089] Wherein, the liquid to be tested flows into the two-way piston pump through the effective chamber, and the two-way piston pump makes the liquid to be tested flow through the core sample in the high-temperature and high-pressure core holder;

[0090] The pressure collection device is used to collect the real-time pressure of the liquid to be tested. The pressure collection end of the differential pressure collection device is set on both sides of the high temperature and high p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com