Iron and steel continuous casting equipment oriented method and device for forecasting faults

A technology for steel continuous casting and fault prediction, which is applied in the direction of measuring devices, machine/structural component testing, special data processing applications, etc. It can solve equipment management and production management services, state information with many parameters, and fault prediction cannot be made, etc. problem, achieve the effect of reducing the trouble of wiring and reducing the application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

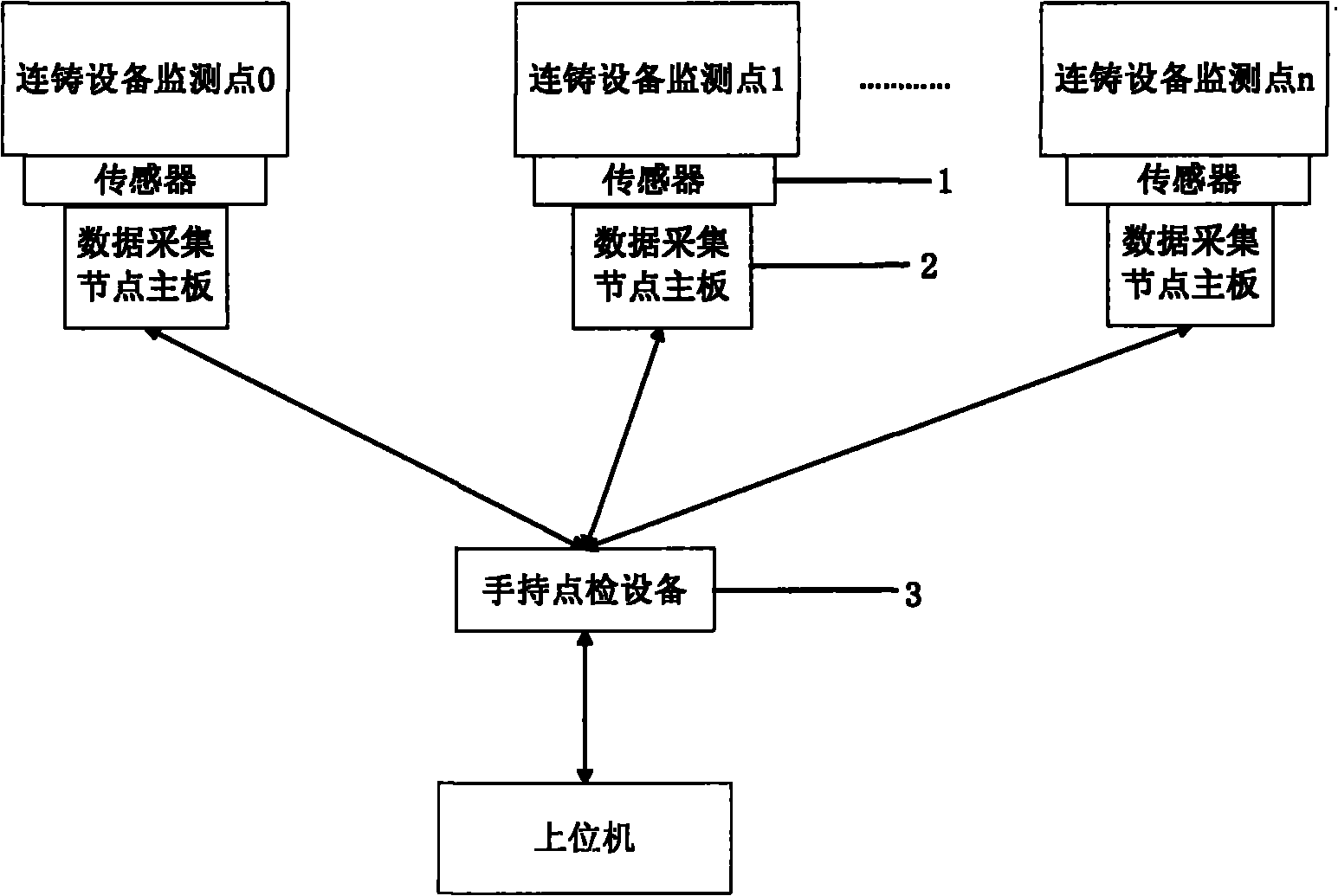

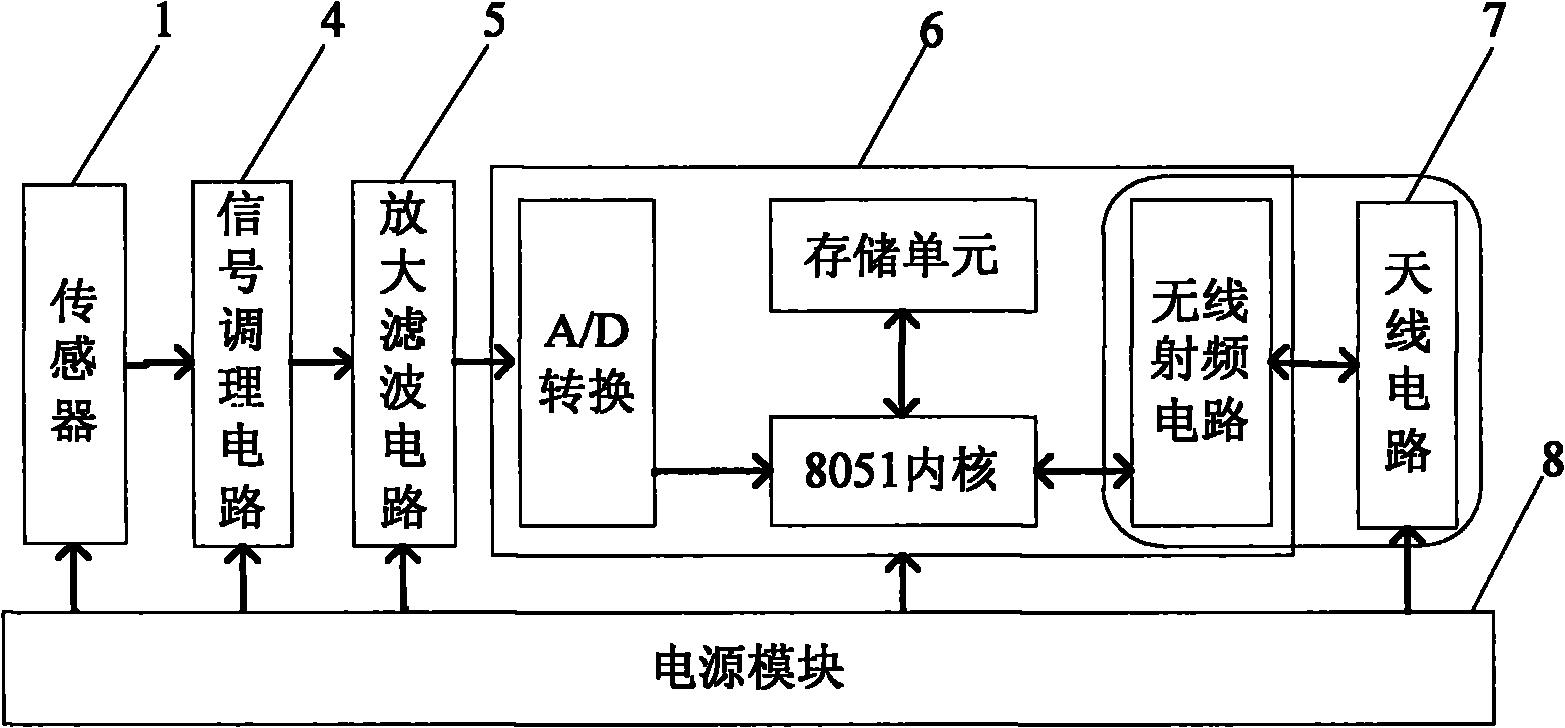

[0040] Such as figure 1 As shown, a device oriented to a fault prediction method for steel continuous casting equipment consists of sensors 1 (acceleration vibration sensor, thermocouple temperature sensor, electromagnetic flow sensor, electromagnetic pressure sensor and eddy current sensor) that collect various state parameters of continuous casting equipment device), data acquisition node main board 2 and hand-held inspection equipment 3. The acceleration vibration sensor monitors the vibration displacement of the rotating machinery bearing, the thermocouple temperature sensor monitors the temperature of different points of the equipment, the electromagnetic flow sensor monitors the flow of cooling water, the electromagnetic pressure sensor monitors the oil and gas lubrication terminal pressure, and the eddy current sensor monitors the motor current. The voltage signals corresponding to the output of each sensor are connected to the main board 2 of the data acquisition node;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com