Preparation method of wire harness

A wire harness and wire technology, applied in the field of wire harnesses, can solve problems such as the inability to improve the production efficiency of wire harnesses and the inability to weld multiple wire harnesses at the same time, and achieve the effect of convenient operation and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a wire harness, the processing steps of which are as follows:

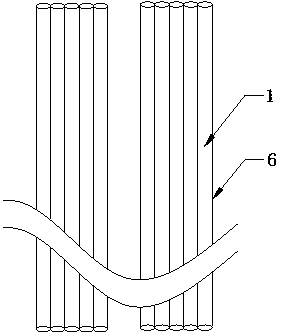

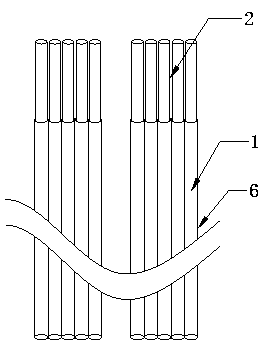

[0034] 1. Wiring and positioning: Carry out wiring on a professional positioning fixture according to the process requirements. The number of wiring groups is two groups. After the wiring is qualified, the positioning can be completed. The wiring of two groups of wires 1 can be completed at one time, such as figure 1 shown.

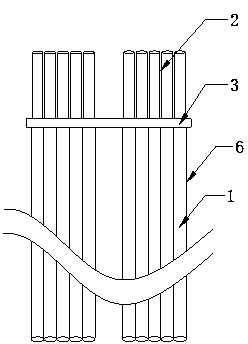

[0035] 2. Laser and half-stripping: According to the process requirements, calculate the laser size and half-stripping size of multiple groups of wires 1, determine the position of the laser, and use the laser machine to laser multiple groups of wires 1 at one time; place the multiple groups of wires 1 that have been lasered in half Positioning in the stripping area, and then half-stripping the outer sheath 6 and the isolation layer of the wire 1 through the half-stripping machine (the isolation layer is a layer inside the outer sheath 6), forming the first laser...

Embodiment 2

[0042] Such as Figure 7 Shown is the welding head 7 for welding the ground sheet 3, the welding head 7 includes two welding parts 71, the welding surface of each welding part 71 is provided with a coating structure for welding the wire 1, the coating structure includes several continuous concave The number and shape of the groove 72 and the groove 72 match the wire rod, meeting the requirements of welding. During welding, the cladding structure of the welding head 7 is directly in contact with the wire rod 1 for welding, the welding head 7 and the lower welding head 8 work at the same time, and the lower welding head 8 is a flat welding head, which jointly completes the welding of the grounding piece 2, as Figure 7 shown. Similarly, welding of 3 groups, 4 groups or more than 4 groups can be carried out at one time. The number of corresponding welding parts 71 is set to be the same as the number of groups, and the positioning jig is provided with wiring grooves corresponding...

Embodiment 3

[0044] The rest are the same as in Embodiment 1, except that the half-stripped size of the wire 1 is 2.0±0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com