Automatic speed changing electric driven hub

A technology of automatic transmission and electric wheel hub, applied in electric components, vehicle gearboxes, bicycles, etc., can solve the problem that the driver cannot be automatically detected, corrected and excluded, the motor power and driving resistance are difficult to match, and it is difficult to accommodate the new technology of automatic transmission. and other problems, to achieve the effect of compact circuit layout rules, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

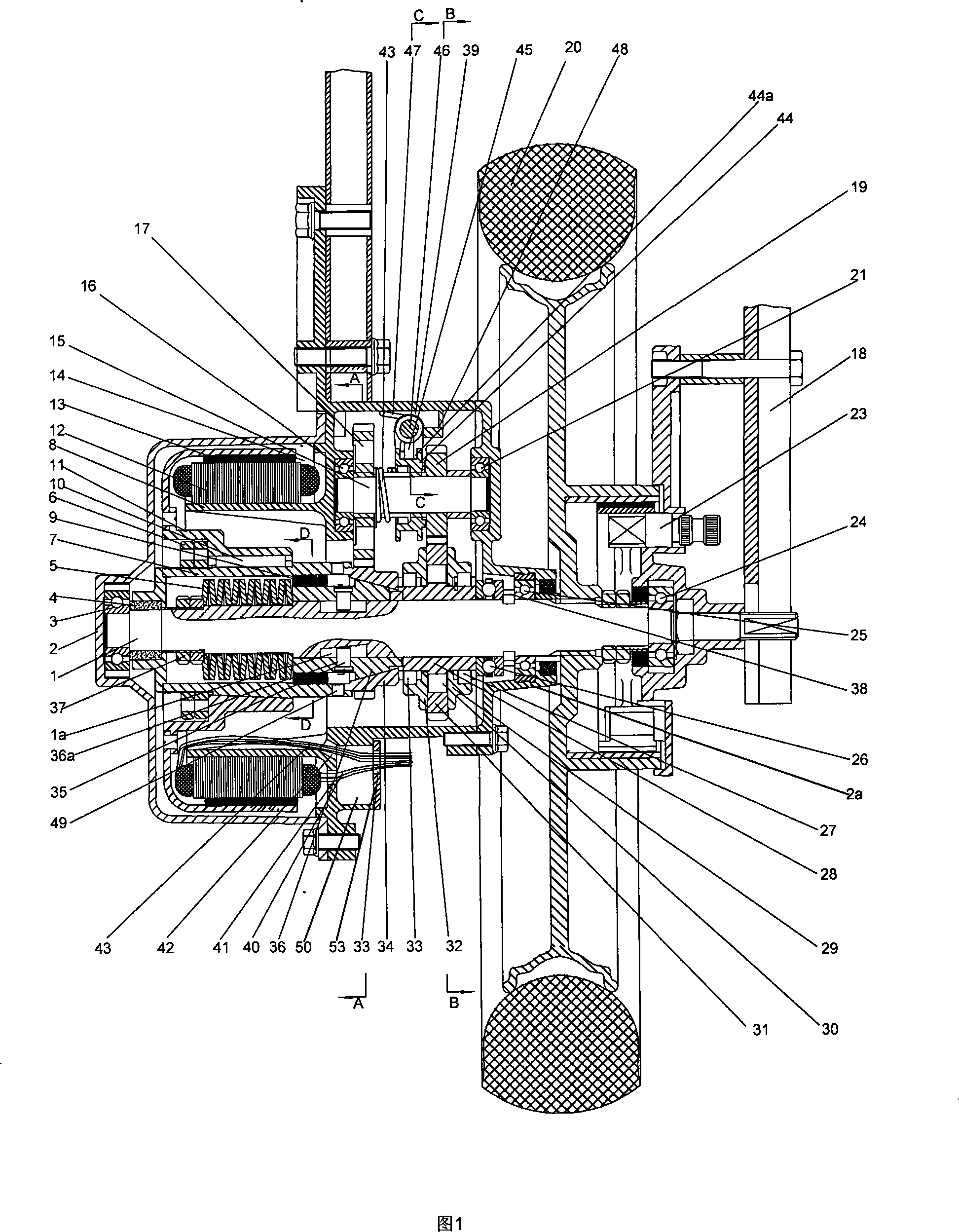

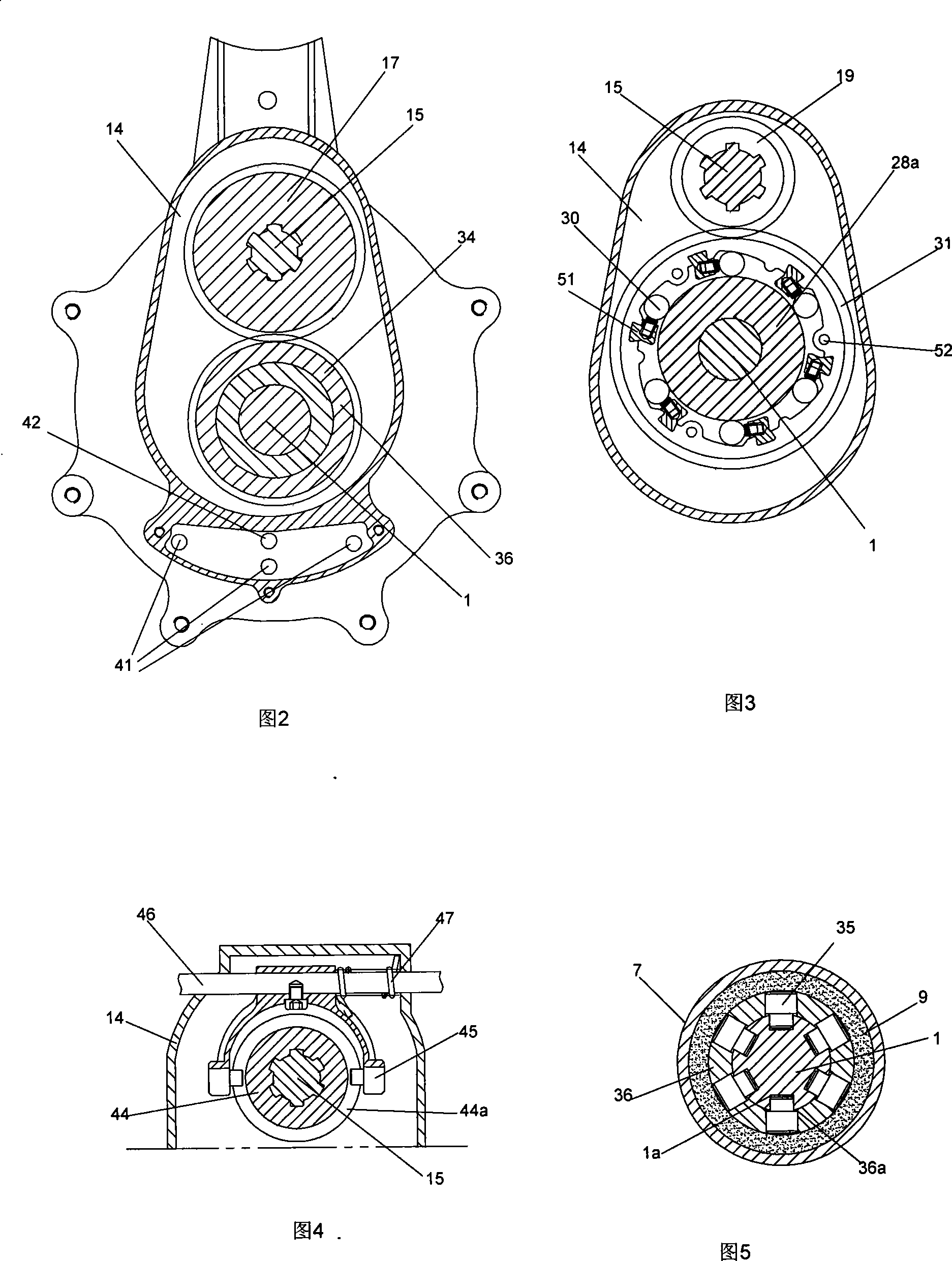

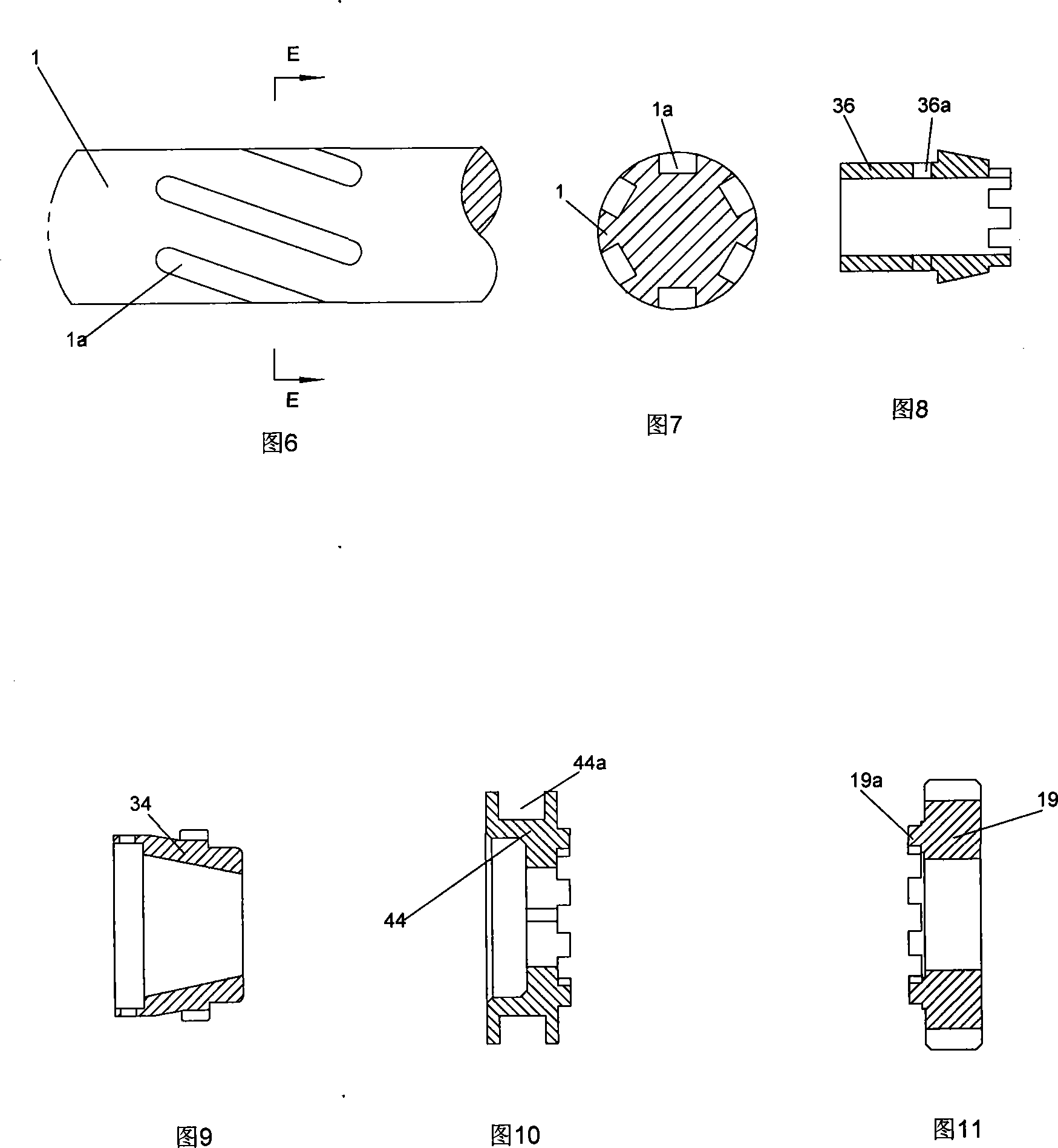

[0040] Fig. 1 is a schematic diagram of the axial section structure of the present invention, as shown in the figure: the transmission shaft 1 of this embodiment rotates counterclockwise from left to right when it is in operation, and the motor is an outer rotor motor.

[0041] The automatic variable speed electric hub comprises a left hub frame 22, a right hub frame 18, a box body 14, a motor, a transmission shaft 1, a wheel 20 and a braking device 23 arranged on the transmission shaft, the inner ring of the wheel 20 and the outer circle of the camshaft 1 The left hub frame 22 and the right hub frame 18 are fixedly connected with the box body 14 through fixing bolts; the box body 14 is fixedly connected with the left hub frame 22, and the brake device 23 is provided with an external bracket, and the external bracket is connected to the right hub frame. The frame 18 is fixedly connected by a spline, and the part of the camshaft 1 protruding from the box body 14 is fixedly match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com