Refining method of high-speed tool steel

A technology of high-speed tool steel and high-speed steel, which is applied in the direction of improving process efficiency to achieve the effects of strengthening refining function, improving yield and thin eutectic carbide network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

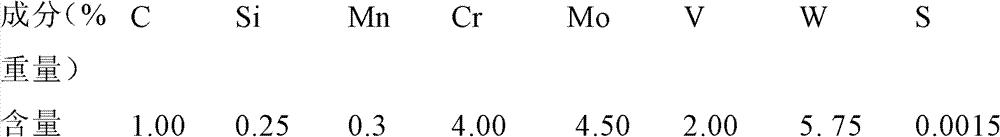

[0017] Example 1, the refining of M2 high-speed tool steel recycled materials.

[0018] Get the metal material that 1.4 tons of high-speed tool steel scraps and 0.4 tons of low-carbon carbon steel scraps form and an appropriate amount of alloying agent are raw materials, and the alloying agent of the present invention is to carry out composition Conventional alloys containing Si, Mn, Cr, Mo, V, W and other elements required for adjustment;

[0019] Putting the above-mentioned high-speed steel scrap and low-carbon carbon steel scrap into an intermediate frequency induction furnace for melting;

[0020] Adding 1.2% of metal material fluorite and carbon powder to make slag, the ratio of fluorite and carbon powder is 1:2;

[0021] After the above-mentioned metal materials in the furnace are completely melted, Al powder and C powder are added on the slag surface for diffusion deoxidation. According to the chemical composition analysis of the molten steel, use the above-mentioned ...

Embodiment 2

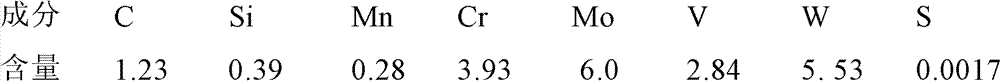

[0025] Embodiment 2, the preparation method of M3 high-speed steel flat wire.

[0026] Get 1.4 tons of high-speed steel waste chips and 0.65 tons of low-carbon carbon steel scrap steel scrap metal material and an amount of alloying agent as raw material, the definition of this alloying agent is the same as embodiment 1;

[0027] Putting the above-mentioned high-speed steel scrap and low-carbon carbon steel scrap into an intermediate frequency induction furnace for melting;

[0028] Add 1.5% of metal material fluorite and carbon powder to make slag, the ratio of the fluorite and carbon powder is 1:2.

[0029] Add Al powder and C powder on the slag surface for diffusion deoxidation treatment. According to the chemical composition analysis of the molten steel, use the alloying agent mentioned above to adjust the chemical composition of the steel; when the temperature of the molten steel reaches 1520°C-1560°C, remove the slag layer on the surface of the molten steel, then insert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com