Rare earth yttrium doped molybdenum disulfide self-lubricating composite coating and preparation method thereof

A composite coating, molybdenum disulfide technology, used in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems such as poor coating quality and equipment susceptible to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

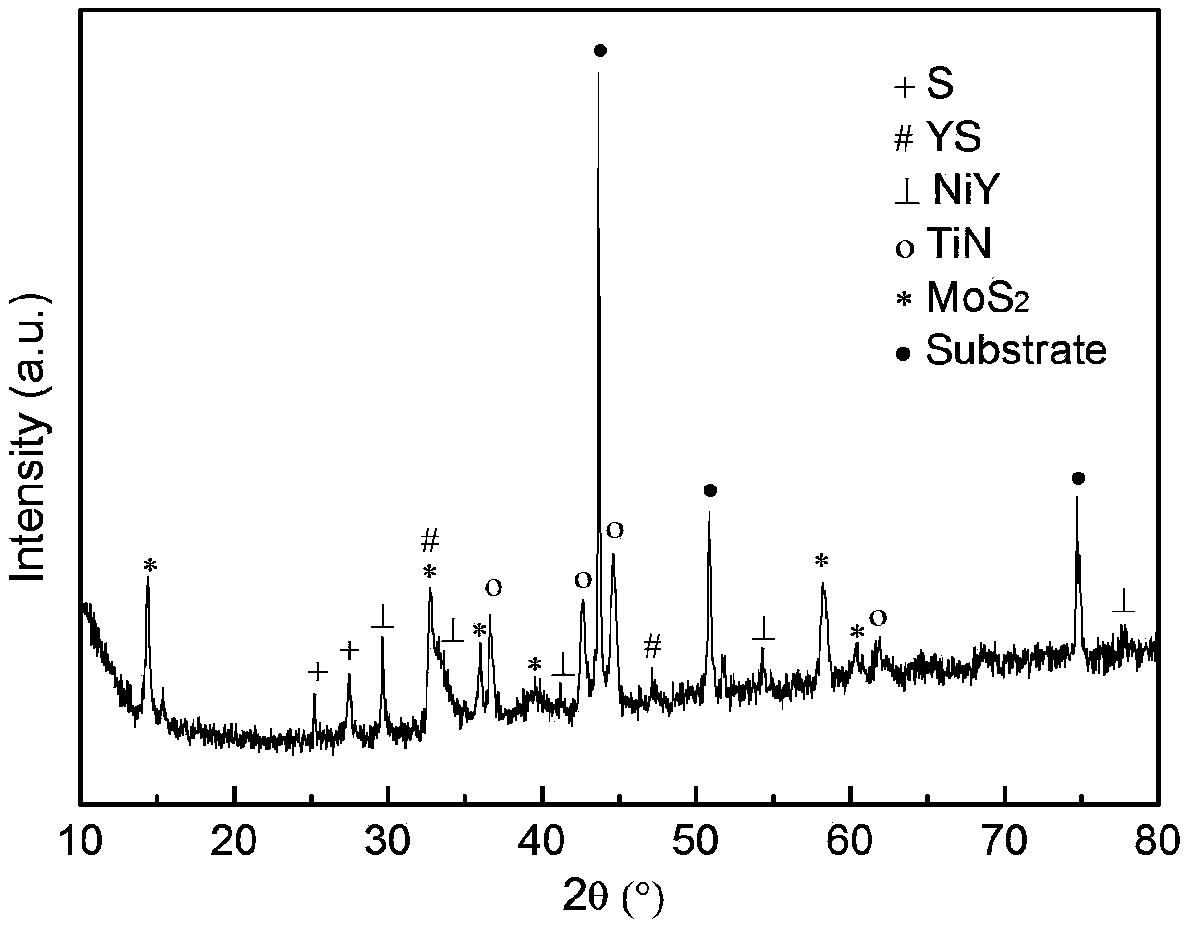

[0066] The invention provides a high-performance CVD-MoS with weak corrosion to equipment 2 A method for preparing a self-lubricating composite coating, the steps of the method are as follows:

[0067] (1) In order to prevent by-products from corroding equipment and improve the quality of the coating, the present invention uses molybdenum trioxide (MoO 3 ) powder and sulfur (S) powder as precursors;

[0068] (2) with Ar and H 2 As a carrier gas and shielding gas;

[0069] (3) Through yttrium chloride hexahydrate (YCl 3 ·6H 2 O) The rare earth element yttrium is introduced into the coating, which greatly improves the MoS 2 Coating structure.

[0070] At the same time, the molybdenum trioxide powder in the present invention is analytically pure, with an average particle size of ≤10 μm and a purity of 99.5%.

[0071] The sulfur powder is analytically pure sublimated sulfur with a purity of 99.95%.

[0072] The yttrium chloride hexahydrate (YCl 3 ·6H 2 O) is analytically...

Embodiment 1

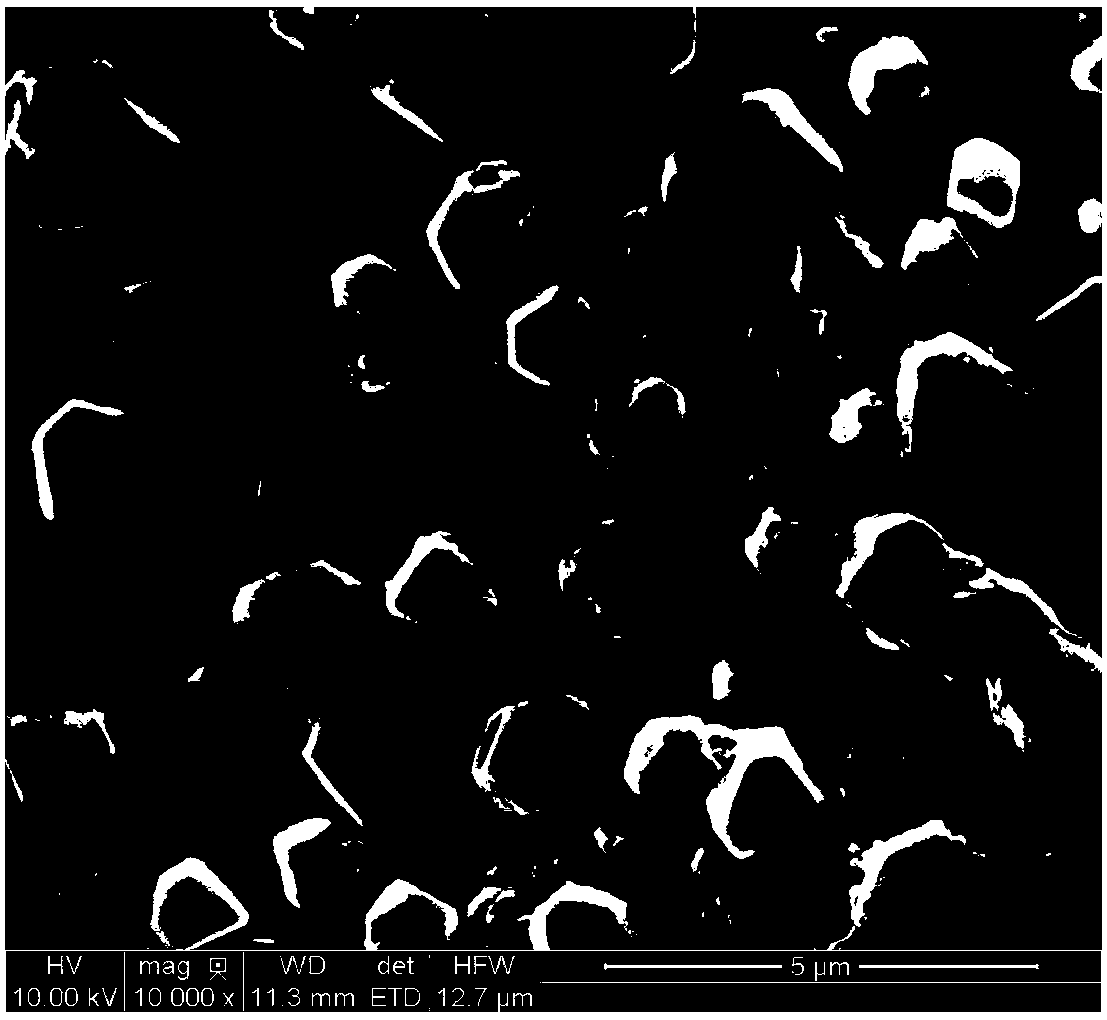

[0085] First weigh 30mg of MoO with a purity of 99.5% 3 Powder and 10 mg of YCl with a purity of 99.99% 3 ·6H 2The O powder is placed side by side on one end of the ceramic boat, and the 304 stainless steel substrate with a titanium nitride (TiN) coating is placed on the other end of the ceramic boat, with a distance of 7 cm between the two. This ceramic boat is placed in the high temperature zone of the tube furnace; Put 1.2g of sulfur powder with a purity of 99.95% into another ceramic boat, and place it in the low temperature area where the heating belt is wound. Then the tube furnace was sealed and evacuated, and then high-purity argon gas was introduced. After doing this twice, the tube furnace starts to heat up. Heating the molybdenum source substrate area to 200°C in 10 minutes, flushing with high-purity argon gas to keep the pressure for 10 minutes, vacuuming for 30 minutes, then raising the temperature to 770°C at a rate of 20°C / min. At this point, the heating bel...

Embodiment 2

[0088] First weigh 60 mg of MoO with a purity of 99.5% 3 The powder is placed on one end of the ceramic boat, and the 304 stainless steel substrate with a titanium nitride (TiN) coating is placed on the other end of the ceramic boat, with a distance of 7cm between the two. The ceramic boat is placed in the high temperature zone of the tube furnace; 99.95% sulfur powder is put into another ceramic boat, put it in the low temperature area where the heating belt is wound. Then the tube furnace was sealed and evacuated, and then high-purity argon gas was introduced. After doing this twice, the tube furnace starts to heat up. Heating the molybdenum source substrate area to 200°C in 10 minutes, flushing with high-purity argon gas to keep the pressure for 10 minutes, vacuuming for 30 minutes, then raising the temperature to 770°C at a rate of 20°C / min. At this point, the heating belt starts to heat the sulfur powder to 130°C until it melts. The tube furnace continued to heat up to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com