Revolving parts electroforming process and device

A processing device and processing method technology, applied in electroforming, electrolysis process, etc., can solve problems such as long electroforming time and unsatisfactory surface quality, achieve the effect of smooth and bright surface, compact structure, and increase electroforming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

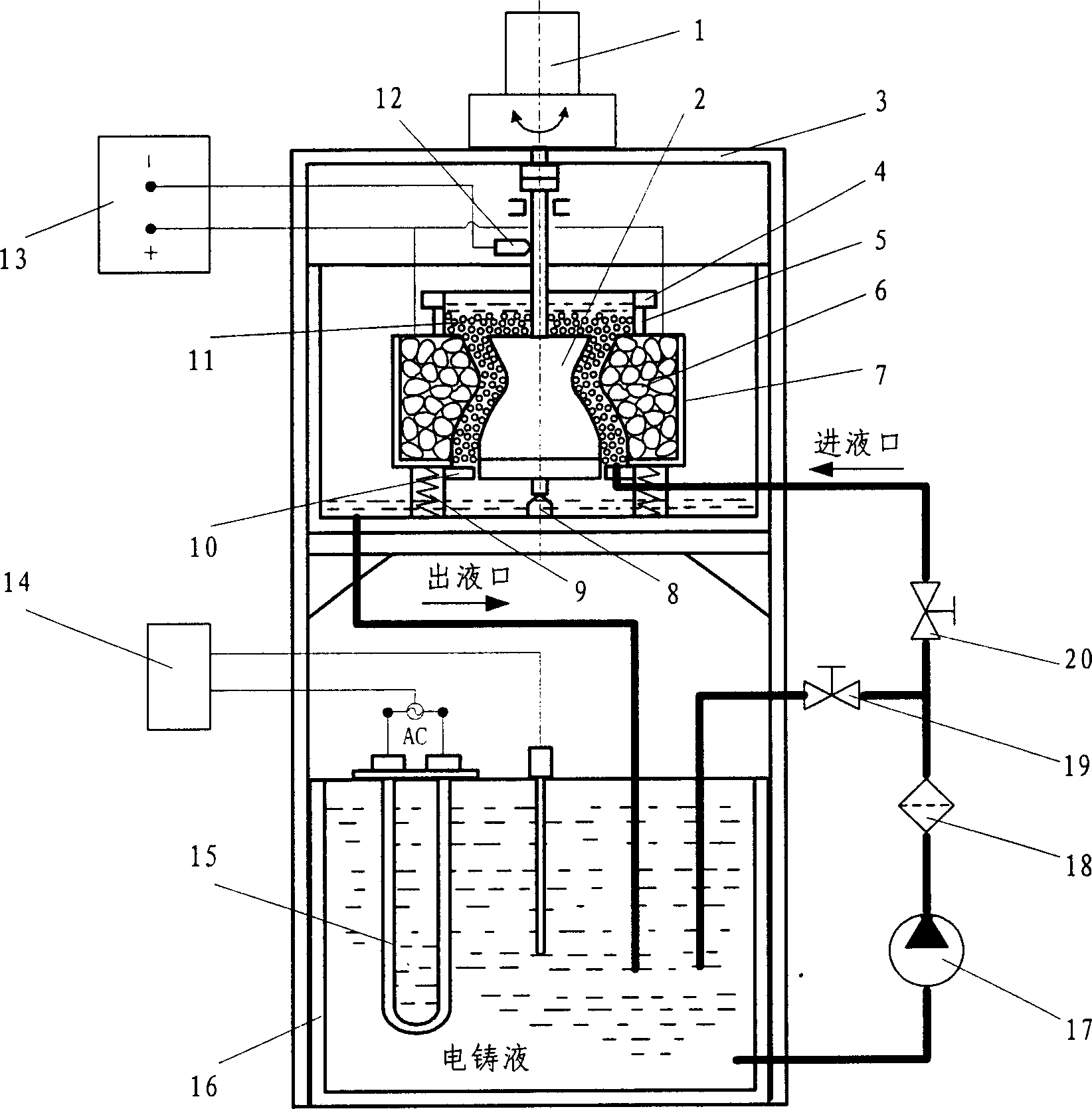

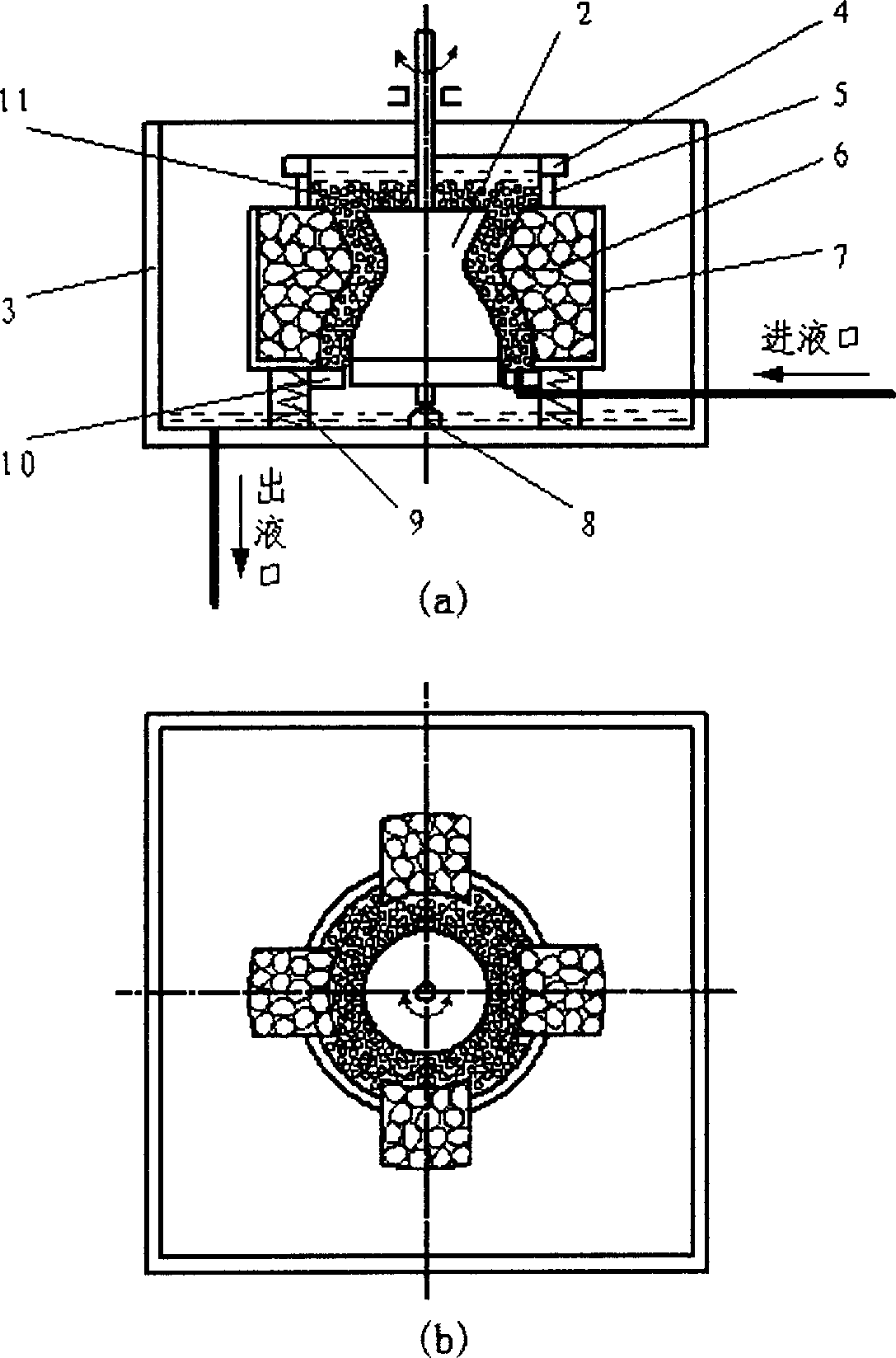

[0030] Combine figure 1 with figure 2 Describe the device structure of the present invention:

[0031] figure 1 It is a schematic diagram of the structure of the electroforming processing device for rotating parts. The device of the present invention includes a motor 1, a machine bed 3, a vibration source 9, a conductive device 12, an electroforming power supply 13, a temperature control device 14, a heater 15, a liquid storage tank 16, a magnetic pump 17, a filter 18, a ball valve 20, Overflow valve 19. It is characterized in that the electroforming process device includes the rotating movement of the core mold 2 and the vibration of the cathode basket 5 acting together on the hard particles 11, causing them to perform a continuous compound movement and uniformly rubbing and perturbing the surface of the electroforming layer. ; The independent cathode basket 5 and the position adjustable anode basket 7 constitute the deposition unit, which can be applied to parts with differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com