Wetting method of aluminum foil and its wetting pool, and method of manufacturing battery packaging film

A manufacturing method and technology of aluminum foil, which is applied to secondary batteries, battery pack parts, battery boxes/coatings, etc., and can solve the problems that aluminum foil is easily corroded by electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

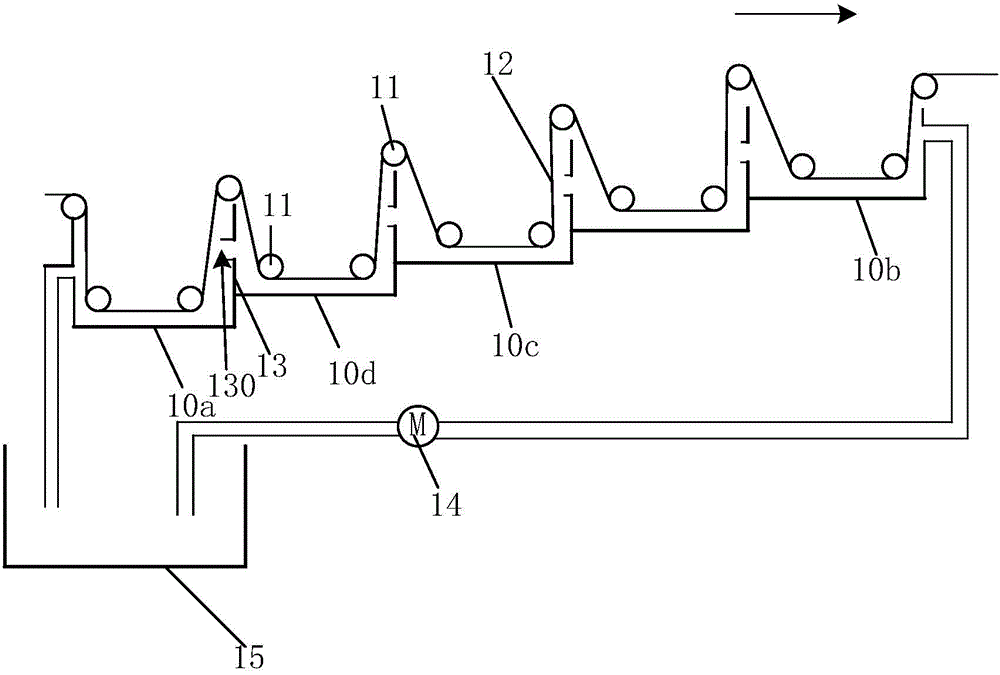

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

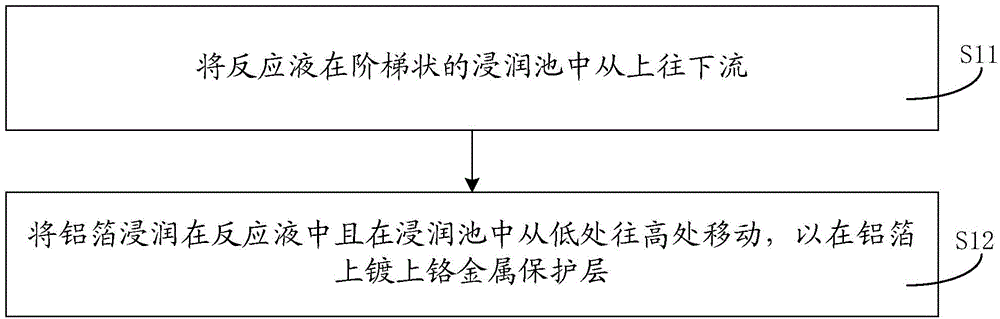

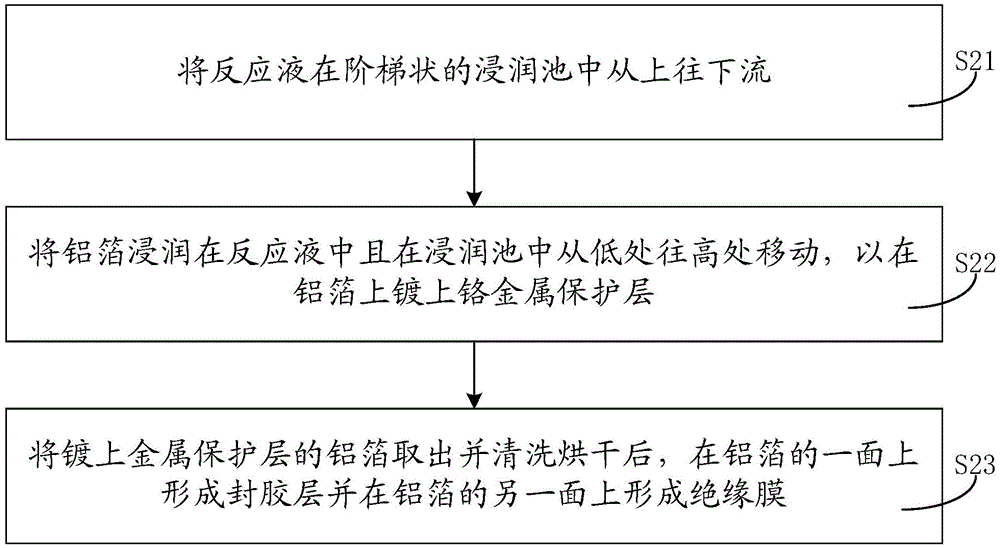

[0021] see figure 1 , figure 1 is a flow chart of a preferred embodiment of the method of soaking aluminum foil of the present invention. The aluminum foil impregnation method is used to deposit a protective layer of chromium metal on the aluminum foil, wherein the aluminum foil is used in the packaging film of the battery. In this embodiment, the soaking method of aluminum foil comprises the following steps:

[0022] Step S11: Flow the reaction solution from top to bottom in the stepped infiltration pool.

[0023] Before step S11, a reaction solution containing chromium ions is prepared so that when the aluminum foil is soaked in the reaction solution, the reaction solution can deposit chromium metal on the surface of the aluminum foil.

[0024] Step S12: soaking the aluminum foil in the reaction solution and moving from a low place to a high pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com