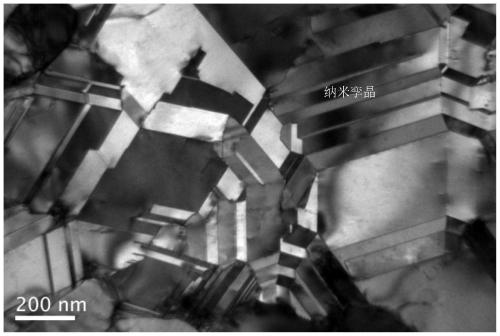

Preparation method of copper based graphene composite with high heat conductivity

A composite material and graphene technology, applied in electrolytic coatings, current conduction devices, electrodes, etc., can solve the problems of insignificant performance improvement, poor film compactness, and high equipment requirements, and achieve improved nucleation rate, low cost, and ratio reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition ratio of the graphene copper electrodeposition solution is: copper sulfate pentahydrate 200g / L, graphene 0.05g / L, and the balance is deionized water; the concentration of additives is: thiourea 2mg / L, boric acid 1g / L , polyethylene glycol fatty acid ester 10mg / L; activate the plate, pickling to remove oil and rust, remove the surface oxide film, the activation solution composition is: 50mL sulfuric acid and 350ml deionized water; the process environment of the deposition solution is: temperature 20°C, pH=0.5; the electrical parameters of DC electrodeposition are: current density is 180mA / cm 2 , the duty cycle is 70%, the deposition frequency is 300Hz, and the electrodeposition time is 0.5h. In this case and under the process conditions, the deposited layer is uniform in thickness, about 30 μm thick, bright in surface and average in density. The thermal conductivity of the prepared deposited layer can reach 390W / m.k, and the tensile strength can reach 313...

Embodiment 2

[0030] The composition ratio of the graphene copper electrodeposition solution is: copper sulfate pentahydrate 200g / L, graphene 1.0g / L, and the balance is deionized water; the concentration of additives is: thiourea is 5mg / L, boric acid is 4g / L , polyethylene glycol fatty acid ester 20mg / L; activate the plate, pickling to remove oil and rust, remove the surface oxide film, the activation solution composition is: 50mL sulfuric acid and 350ml deionized water; the process environment of the deposition solution is: temperature 30°C, pH=1.0; the electrical parameters of DC electrodeposition are: current density is 180mA / cm 2 , the duty cycle is 70%, the deposition frequency is 500Hz, and the electrodeposition time is 0.5h. In this case and under the process conditions, the thickness of the deposition layer deposited is uniform, the thickness is about 40 μm, the surface is bright, and the compactness is good. The thermal conductivity of the prepared deposition layer can reach 636W / m...

Embodiment 3

[0033] The composition ratio of the graphene copper electrodeposition solution is: copper sulfate pentahydrate 200g / L, graphene 2g / L, and the balance is deionized water; the additive concentration is: thiourea is 10mg / L, boric acid is 6g / L, Polyethylene glycol fatty acid ester 30mg / L; Activate the plate, pickling to remove oil and rust, remove the surface oxide film, the activation solution composition is: 50mL sulfuric acid and 350ml deionized water; the process environment of the deposition solution is: the temperature is 30°C, pH=1.5; the electrical parameters of direct current electrodeposition are: the current density is 180mA / cm 2 , the duty cycle is 70%, the deposition frequency is 500Hz, and the electrodeposition time is 1h. In this case and under the process conditions, the thickness of the deposition layer deposited is uniform, the thickness is about 80 μm, the surface is bright, and the compactness is good. The thermal conductivity of the prepared deposition layer c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com