High-entropy alloy in-situ preparation method and product by laser additives

A high-entropy alloy and laser additive technology, applied in the field of alloy materials, can solve the problems of large high-entropy alloy system, increased cost, formation mechanism and strengthening mechanism, etc., and achieve high efficiency and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

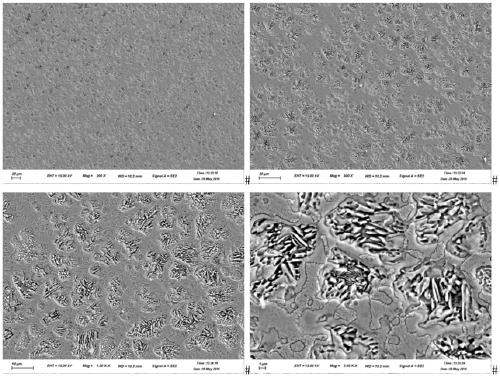

Image

Examples

Embodiment 1

[0032] Step 1, mixing raw materials, Fe, Co, Cr, Ni, Ti spherical powder with a purity of 99.9%, the particle size of the spherical powder is in the range of 50-150 μm, and Fe, Co, Cr, Ni, Ti spherical powder in equal molar ratio Mixing, the mixed spherical powder was mixed in a three-dimensional mixer for 3 hours, the cylinder speed was 30 r / min, and the uniformly mixed spherical powder was dried in a vacuum dryer for 6 hours, the temperature was 80 degrees Celsius, and the vacuum degree was Relative pressure -0.95MPa, sealed and stored after drying;

[0033] Step 2, additive preparation, the substrate is made of 304 stainless steel, the size is 100 × 100 × 15 mm, the surface of the substrate is ground with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol, respectively, and the The spherical powder obtained after the completion of step 1 was put into the printer silo, and the LMD-8060 printer of Nanjing Zhongke...

Embodiment 2

[0042] Step 1, mixing raw materials, Fe, Co, Cr, Ni, Ti spherical powder with a purity of 99.9%, the particle size of the spherical powder is in the range of 50-150 μm, and the Fe, Co, Cr, Ni, Ti spherical powders in an equal molar ratio Mixing, mixing the mixed spherical powder in a three-dimensional mixer for 3 hours, the cylinder rotating speed is 30r / min, drying the uniformly mixed spherical powder in a vacuum dryer for 6 hours, the temperature is 80 degrees Celsius, and the vacuum degree is Relative pressure -0.95MPa, sealed after drying;

[0043] Step 2, additive preparation, the substrate is made of 304 stainless steel with a size of 100×100×15mm, the surface of the substrate is polished with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol respectively, and the The spherical powder obtained after the completion of step 1 is put into the printer silo, and the LMD-8060 printer of Nanjing Zhongke Yuchen Com...

Embodiment 3

[0046] Step 1, mixing raw materials, Fe, Co, Cr, Ni, Ti spherical powder with a purity of 99.9%, the particle size of the spherical powder is in the range of 50-150 μm, and the Fe, Co, Cr, Ni, Ti spherical powders in an equal molar ratio Mixing, mixing the mixed spherical powder in a three-dimensional mixer for 3 hours, the cylinder rotating speed is 30r / min, drying the uniformly mixed spherical powder in a vacuum dryer for 6 hours, the temperature is 80 degrees Celsius, and the vacuum degree is Relative pressure -0.95MPa, sealed after drying;

[0047] Step 2, additive preparation, the substrate is made of 304 stainless steel with a size of 100×100×15mm, the surface of the substrate is polished with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol respectively, and the The spherical powder obtained after the completion of step 1 is put into the printer silo, and the LMD-8060 printer of Nanjing Zhongke Yuchen Com...

PUM

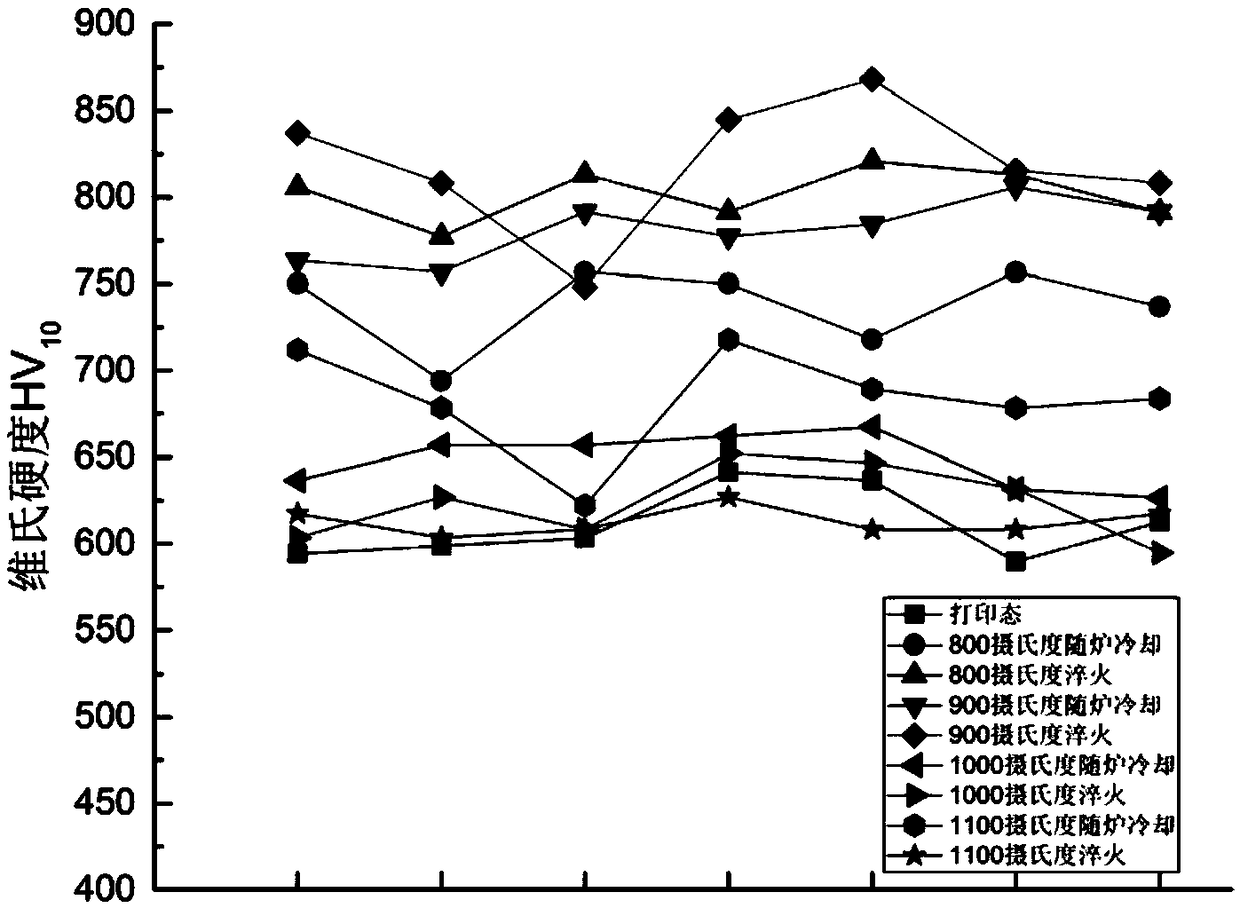

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com