Preparation method of high-performance ceramic

A high-performance, ceramic technology, applied in the field of ceramic materials, can solve the problems of inability to realize 3D printing intelligent manufacturing and near-net-size molding, difficult to control product size, uneven product shrinkage, etc., achieving short cycle time, low cost, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

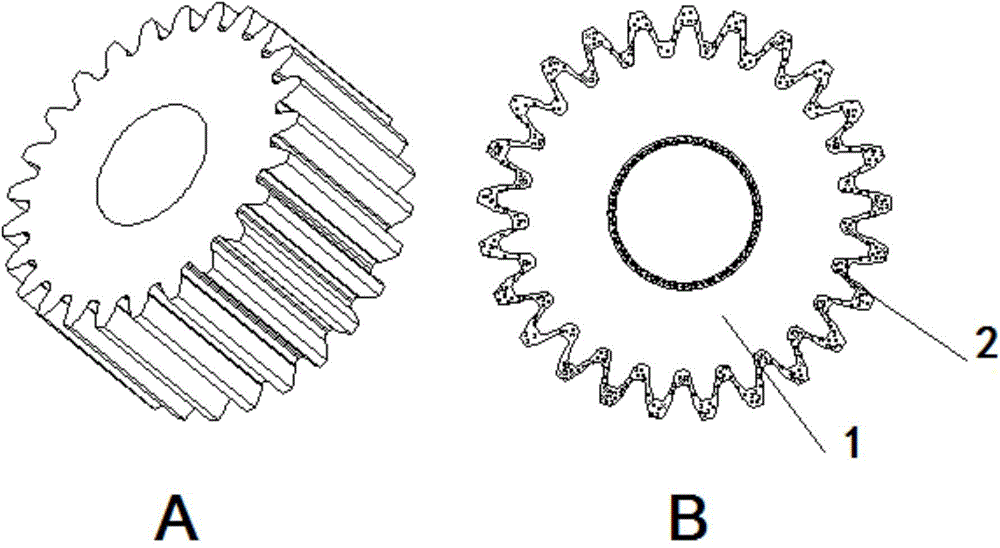

[0032] Example 1: Si 3 N 4 Gear parts (participating in figure 1 , A is the gear blank, B is the gear blank covered with hot isostatic pressing, in which 1 is the gear blank; 2 is the jacket)

[0033] (1) Design the 3D digital model of the gear and its cover with 3D modeling design software (such as UG, Solidworkds), and convert it into STL format with slice layering software and import it into the selective laser sintering equipment.

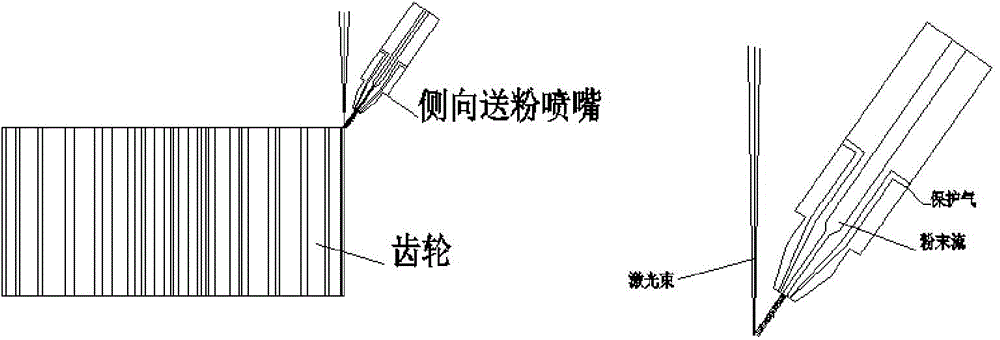

[0034] (2) According to a certain proportion, Si mixed with sintering aids 3 N 4 The powder and double atmosphere A-type epoxy resin powder are mixed uniformly by ball milling, and then laminated with selective laser sintering equipment to print Si 3 N 4 Gear blanks. Si used 3 N 4 The particle size of powder granulation is 20-150 μm, and the particle size of bisphenol A epoxy resin powder is 10-80 μm. The laser used in the selective laser sintering equipment is 50w CO 2 Laser, preheating temperature 40-60°C, single-layer thickness 0.1...

Embodiment 2

[0043] Embodiment 2: prepare Al 2 o 3 Artificial acetabulum (see Figure 4 )

[0044] (1) Design the three-dimensional digital model of the artificial acetabulum and the metal mold for compression molding with three-dimensional modeling design software (such as UG, Solidworks).

[0045] (2) Al mixed with release agent, sintering aid, binder and other materials 2 o 3 The powder is molded to make the blank of the artificial acetabular prosthesis.

[0046] (3) to Al 2 o 3 The artificial acetabular body is degummed to remove the adhesive. Firstly, the softening point temperature is raised to 90°C at a rate of 4°C / min, then raised to 150°C at a rate of 2°C / min to remove all water vapor, kept for 1 hour, and finally raised to 700°C at a rate of 2°C / min. Keep warm for 2h.

[0047] (4) to Al 2 o 3 The artificial acetabular body was subjected to cold isostatic pressing. The speed of cold isostatic pressing was 2-6 MPa / s, and the pressure was raised to 200-350 MPa. The pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com