Preparation method of diamond/metal-based composite material with high volume fraction

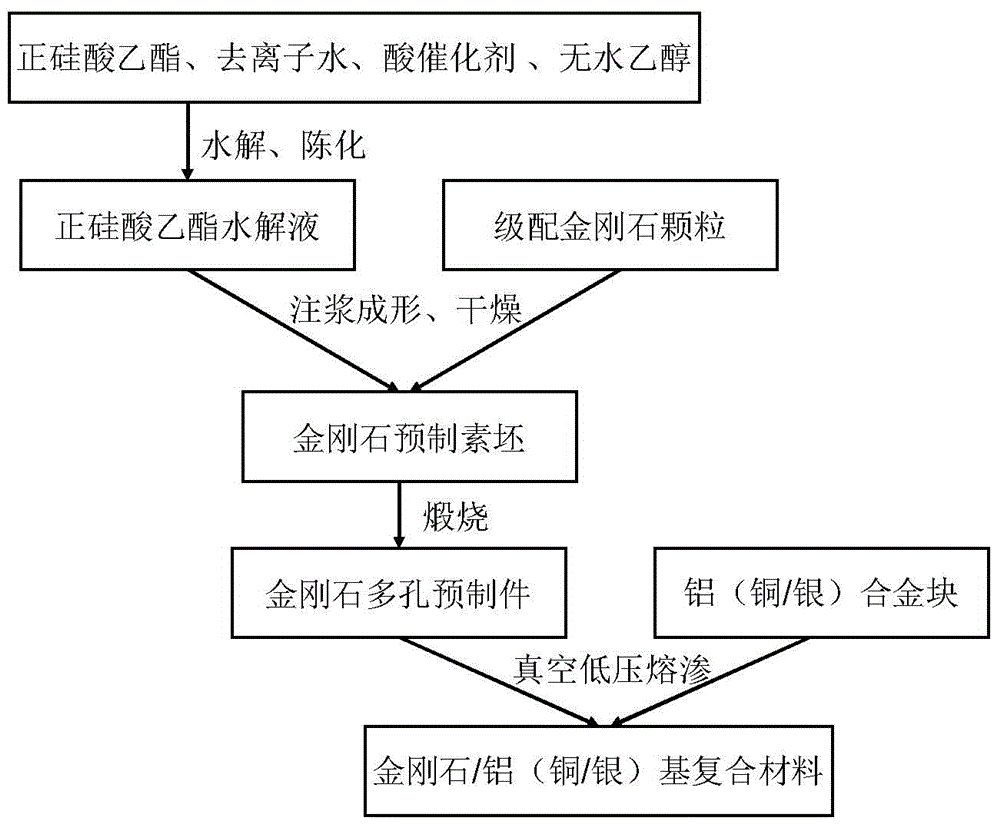

A technology of high volume fraction and composite materials, which is applied in the field of preparation of high volume fraction diamond/metal matrix composite materials, which can solve the problems of affecting the shape and dimensional accuracy of casting preforms, affecting the shape and dimensional accuracy of preforms, and difficulty in degassing, etc. , to achieve the effect of low process equipment requirements, low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

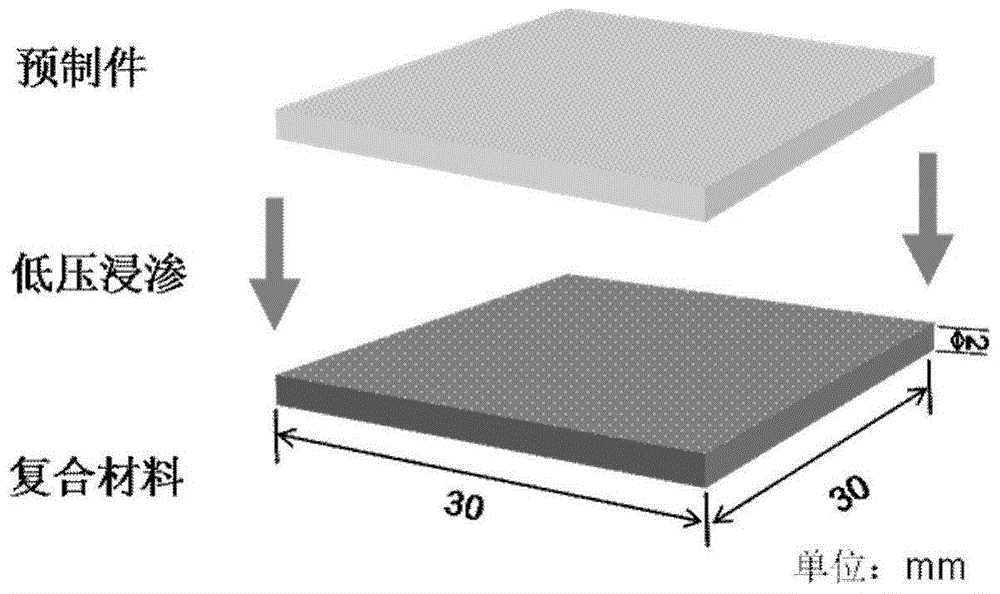

Method used

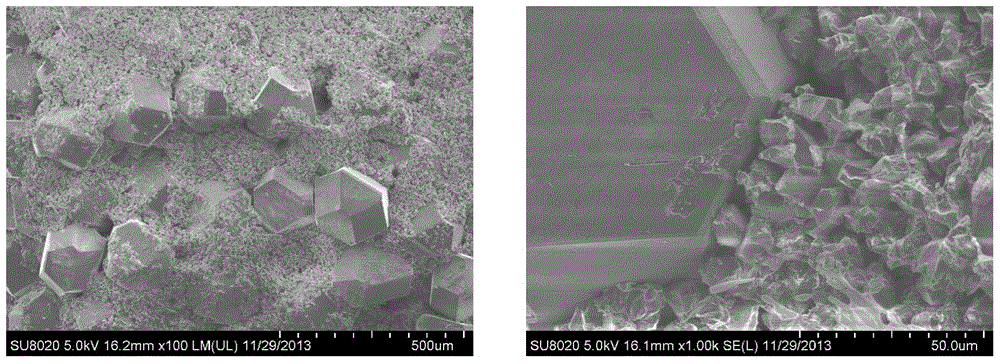

Image

Examples

Embodiment 1

[0040] Raw materials: Analytical pure ethyl orthosilicate (28.8% silica content), commercially available MBD6 diamond coarse powder (particle size 150-180 microns), diamond fine powder (particle size 8-20 microns) and aluminum alloy block (silicon 7%, magnesium 0.5%, the balance is Al).

[0041] 1. Preparation of hydrolyzate

[0042] Mix 3 mol of absolute ethanol, 1 mol of water and 0.05 mol of concentrated hydrochloric acid (mass concentration 36.5%) at room temperature, heat up to 45°C and keep warm, then add 1 mol of tetraethyl orthosilicate under magnetic stirring, stop heating after hydrolysis for 1 hour; After reaching room temperature, it was allowed to stand for 24 hours to obtain a hydrolyzate.

[0043] 2. Preparation of slurry

[0044] Put 1.5g of fine diamond powder and 3.5g of coarse diamond powder into a container and mix them uniformly to obtain a mixed powder, measure 0.6mL of the hydrolyzate prepared in step 1, and dilute the hydrolyzate and absolute ethanol ...

Embodiment 2

[0050] Raw materials: Analytical pure ethyl orthosilicate (28.8% silica content), commercially available MBD6 diamond coarse powder (particle size 150-180 microns), diamond fine powder (particle size 8-20 microns) and aluminum alloy block (silicon 7%, magnesium 0.5%, the balance is aluminum).

[0051] The preparation process of this example is the same as that of Example 1, except that the calcining temperature of the prefabricated green body in the argon atmosphere in step 3 is 750°C, and the volume fraction of the reinforcement in the prepared porous diamond preform is 76%; step 4 The infiltration time of medium vacuum pressure infiltration is 15min. The room temperature thermal conductivity of the diamond / aluminum matrix composite material prepared in this example is 362 W / m·K, and the average linear expansion coefficient is 6.5 ppm / K (30-200° C.).

Embodiment 3

[0053] Raw materials: Analytical pure ethyl orthosilicate (28.8% silica content), commercially available MBD6 diamond coarse powder (particle size 150-180 microns), diamond fine powder (particle size 8-20 microns) and aluminum alloy block (Titanium 0.5%, the balance is aluminum).

[0054] The preparation process of this example is the same as that of Example 1, except that the calcining temperature of the prefabricated green body in the argon atmosphere in step 3 is 950° C., and the volume fraction of the reinforcement in the prepared diamond porous preform is 76%. The room temperature thermal conductivity of the diamond / aluminum matrix composite material prepared in this example is 470 W / m·K, and the average linear expansion coefficient is 6.0 ppm / K (30-200° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com