Iron-based gradient structure gear and manufacturing method thereof

A gradient structure, iron-based technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of easy breakage and peeling, easy breakage, low bonding strength of coating and substrate, etc., to reduce The effect of low cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and embodiments.

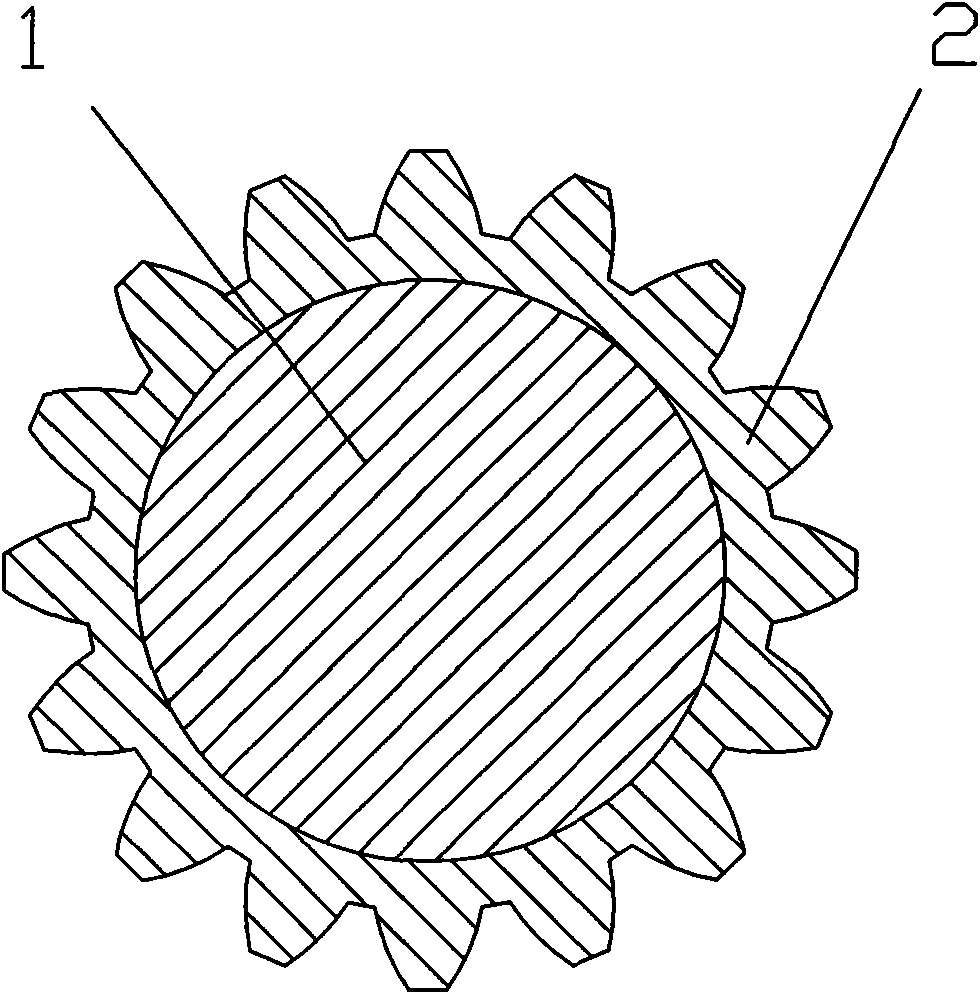

[0017] See figure 1 The outer layer of the core layer 1 is covered with a shell layer 2. The shell layer 2 and the core layer 1 are combined by metallurgy, the core layer 1 is Fe 2Ni, and the shell layer 2 is Fe-2Ni-1, 2, 3Cr.

[0018] The steps of the preparation method are as follows:

[0019] a. Preparation of raw material powder: The gear shell material powder is prepared by weight percentage, taking iron powder 95%, Ni powder 2%, and Cr powder 3%; for gear core material powder preparation, taking iron powder by weight percentage 98%, Ni powder 2%, set a four-pot mixer to mix the powder raw materials evenly;

[0020] b. Preparation of binder: take polyethylene glycol 10-40%, vegetable oil 5-20%, polyethylene 15-30%, plasticizer 1-10%, and paraffin 15-54% by weight. In the blade mixer, mix at 140℃-160 for 1 hour;

[0021] c. Ingredients: the binder and the mixed Fe-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com