Device and method for hydraulic injection filled type extrusion cast forming of molten aluminum magnesium alloy

An aluminum-magnesium alloy and squeeze casting technology, which is applied in the field of material processing engineering, can solve problems such as the inability to achieve near-net shape and easy oxidation of liquid metals, and achieve the effects of preventing oxidation, improving mechanical properties, and avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

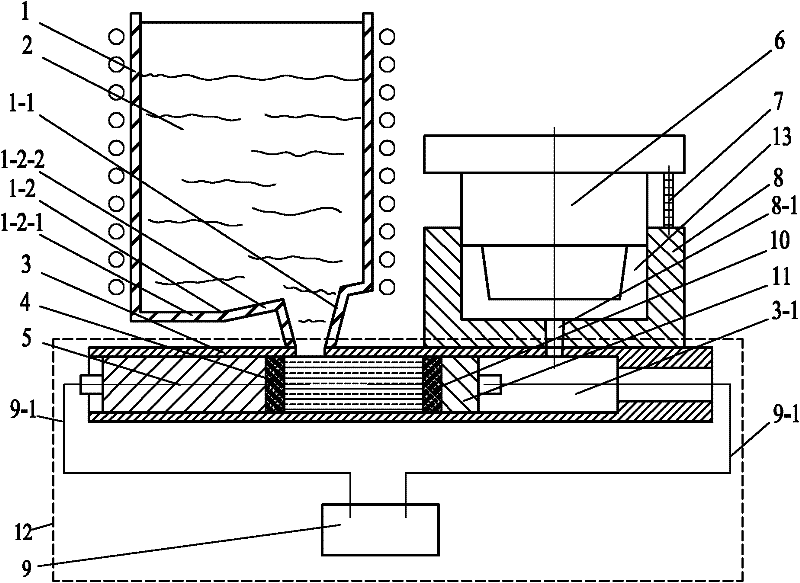

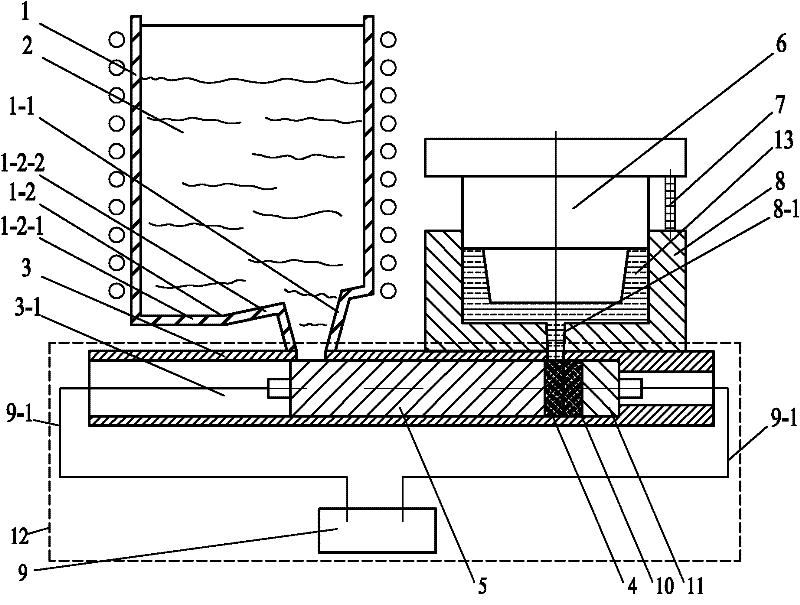

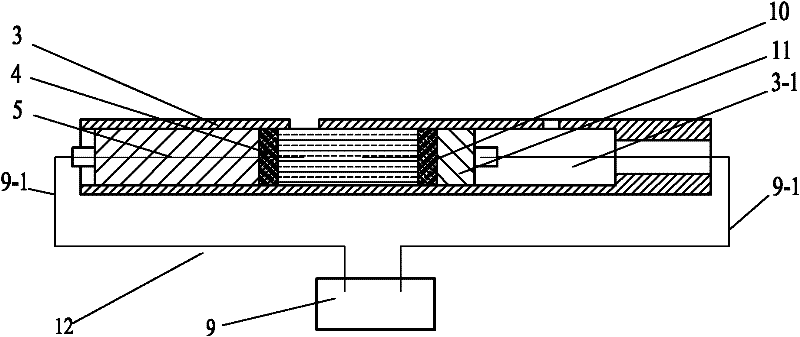

[0016] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, the aluminum-magnesium alloy smelting hydraulic injection filling squeeze casting forming device of this embodiment includes a melting furnace 1, a punch 6, a limit elastic scale 7 and a die 8; There is a feed port 8-1, the punch 6 and the die 8 are co-installed, a cavity 13 is formed between the punch 6 and the die 8, and the limit elastic scale 7 is connected between the punch 6 and the die 8 Between, the bottom plate of the melting furnace 1 is provided with a discharge port 1-1, and the hydraulic injection molding extrusion casting forming device after the aluminum-magnesium alloy is smelted also includes a hydraulic injection device 12, and the hydraulic injection The device 12 includes a push cylinder 3, a first push rod 5, a second push rod 11 and a double-piston rod hydraulic cylinder 9. The push cylinder 3 has a stepped hole 3-1 along its axis, and the melting The fu...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 , figure 2 and Figure 4 To illustrate this embodiment, the bottom plate 1-2 of the melting furnace 1 of this embodiment is made of a horizontal plate 1-2-1 and a parabolic plate 1-2-2, and the parabolic plate 1-2-2 and the horizontal plate 1 The connecting end of -2-1 is lower than the vertex O of the parabolic plate 1-2-2, and the discharge port 1-1 is arranged on the parabolic plate 1-2-2. With such arrangement, the impurities in the molten metal will sink on the horizontal plate 1-2-1, which prevents the impurities in the molten metal from flowing out from the discharge port 1-1, which will affect the quality of the workpiece and the mechanical properties of the workpiece. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, the aluminum-magnesium alloy smelting hydraulic pressure injection filling squeeze casting forming device of this embodiment also includes a first ceramic layer 4 and a second ceramic layer 10, a first push rod 5 and a second push rod The first ceramic layer 4 is provided on the opposite end surface of 11 , and the second ceramic layer 10 is provided on the opposite end surface of the second push rod 11 to the first push rod 5 . With such arrangement, the ceramic layer is in contact with the molten metal, has high temperature resistance, and prevents the molten metal from corroding the push rod. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com